VAL

S

TEAM

ADCA

Produced in accordance with Sound Engineering Practices of the European PED - Pressure Equipment Directive.

IMI P130.08 E 00.20

15

5. START-UP

Before performing the start-up procedure, refer to section 1 – Safety information.

The start-up procedure must be followed every time the product is put back into service.

5.1. Preparation for start-up

Before starting up, make sure the following conditions are met:

• All works on the system have been completed.

• All the necessary safety devices have been installed.

• When required, warning notices are used to alert others that the system is starting

up.

• The product is correctly installed – see section 4 – Installation.

• Referring to these Installation and Maintenance Instructions (IMI), Information Sheet

(IS) and nameplate, check that the product is suitable for the intended installation:

temperature, medium, pressure, temperature, etc. – see section 1.2 – Intended

use.

•

A safety check was performed by qualified personnel. Checking for leaks, structural

damage and integrity of system components.

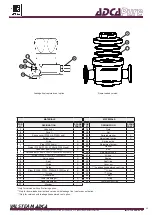

• For spring-loaded regulators, the adjustment spring is completely relaxed. If not,

release tension by turning the adjustment knob (26) counterclockwise.

• For dome-loaded regulators, the dome chamber is depressurized.

RISK OF PRODUCT DAMAGE DUE TO CONTAMINATION

The plant operator is responsible for cleaning the pipelines in the plant as

well as keeping the product well maintained. At start-up,

the presence of

small particles in the medium (dirt, scale, weld splatters, etc.) may damage

the product or cause malfunction.

• Flush pipelines before start-up.

•

Clean protection varnishes from pipes and flanges, leftover paint, graphite,

grease, etc.

•

Use a pipeline strainer or a filter.

NOTICE

5.2. Start-up procedure

1.

Partially open the downstream shut-off valve.

2.

Slowly open the upstream shut-off valve to prevent sudden surges of pressure that

can damage the regulator.