VAL

S

TEAM

ADCA

Produced in accordance with Sound Engineering Practices of the European PED - Pressure Equipment Directive.

IMI P130.08 E 00.20

14

• In steam applications (not recommended for the P130 line), it should be dry and

free of impurities. A humidity separator with an appropriate trapping set trap is

strongly recommended.

• Additionally, for dome-loaded variants make sure:

◦

The gas supply is dry and free of oil.

◦

If a pilot regulator is used, then it should be a self-relieving type and its maximum

outlet pressure to the dome chamber may not exceed the downstream pressure

rating of the P130 regulator.

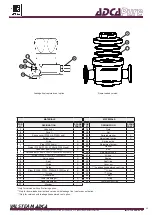

Assembly Drawings (AD) with assembly details and parts lists are available

on request.

NOTE

4.2. Installation procedure

1.

Remove plastic film and other packaging, as well as protective covers which are

placed on clamps or ETO connections. Make sure the regulator is free from foreign

matter.

2.

Handle the regulator carefully to prevent damage to its surface finish.

3. The regulator recommended installation position is horizontal with the adjustment

knob pointing upwards. Other installation positions may increase wear and shorten

its service lifetime.

4. The regulator has an arrow or inlet/outlet designations, be sure that it is installed in

the appropriate direction according to fluid flow.

5. When a clamp ferrule version is being installed, use appropriate gaskets. Sanitary

clamps must respect the system operating limit conditions.

6. When an ETO version is being installed, the welding should be carried out by

qualified personnel following an appropriate orbital welding procedure.

7. For dome-loaded regulators, connect the control pressure line to the dome chamber

threaded port using suitable fittings and tubing.