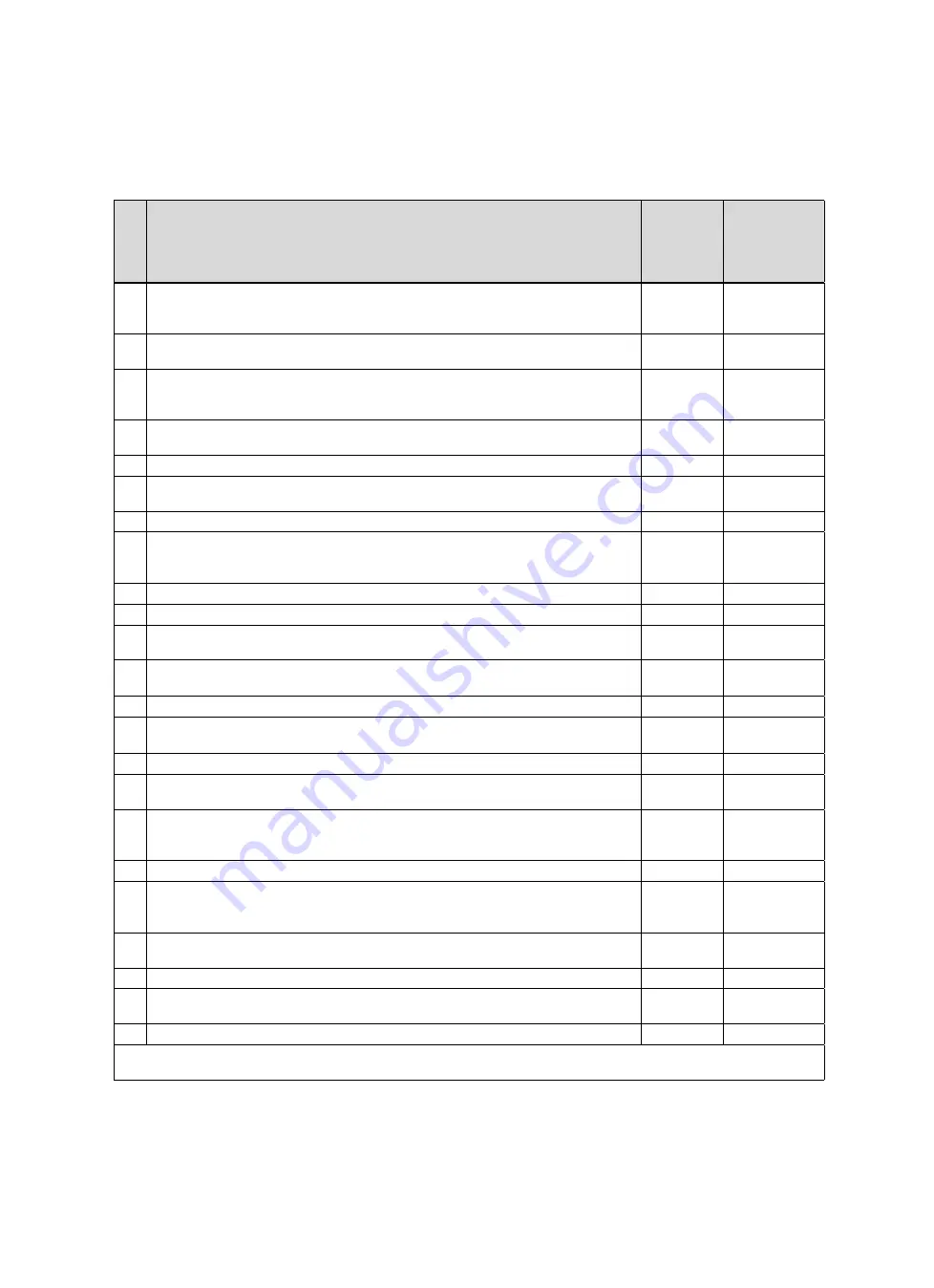

Appendix

40

Installation and maintenance instructions HOME 0020224355_00

G

Inspection and maintenance work

–

Overview

The table below lists the manufacturer requirements with respect to minimum inspection and maintenance intervals. If na-

tional regulations and directives require shorter inspection and maintenance intervals, you should observe these instead of

the intervals listed in the table.

No.

Work

Inspection

(annual)

Maintenance

(must be

carried out at

regular

intervals)*

1

Check the air/flue pipe for leak-tightness and to ensure that it is fastened correctly. Make sure

that it is not blocked or damaged and has been installed in accordance with the relevant In-

stallation Manual.

X

X

2

Check the general condition of the product. Remove any dirt from the product and the vacuum

chamber.

X

X

3

Visually inspect the general condition of the heat exchanger. In doing so, pay particular atten-

tion to signs of corrosion, rust and other defects. If you notice any damage, carry out mainten-

ance work.

X

X

4

Check the gas connection pressure at maximum heat input. If the gas connection pressure is

not within the specified range, carry out maintenance work.

X

X

5

Check the CO

₂

content (air ratio) of the product and, if necessary, adjust it.

X

X

6

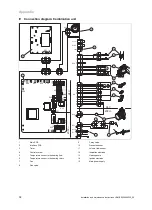

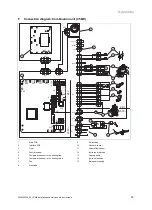

Disconnect the product from the power mains. Check that the plug connections and electrical

connections are correct and make any necessary adjustments.

X

X

7

Close the gas isolator cock and the service valves.

X

8

Drain the product on the water side. Check the pre-charge pressure of the expansion vessel,

and top up the vessel if necessary (approx. 0.03 MPa/0.3 bar under the system filling pres-

sure).

X

9

Check the ignition electrode.

X

X

10

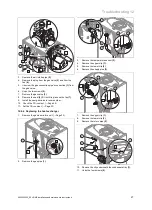

Remove the gas-air mixture unit.

X

11

Replace both burner seals

each time

it is opened and accordingly

each time

maintenance

work is carried out.

X

12

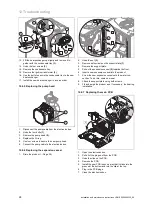

Clean the heat exchanger.

→

Section "Cleaning the heat exchanger"

X

13

Check the burner for damage and replace it if necessary.

X

14

Check the condensate siphon in the product, clean it and, if required, replace it.

→

Section "Cleaning the condensate siphon"

X

X

15

Install the gas-air mixture unit.

Caution: Replace the seals.

X

16

If necessary, if the hot water output is insufficient or the outlet temperature is not reached,

replace the plate heat exchanger.

X

17

Clean the filter in the cold water inlet. Replace the filter if impurities can no longer be removed

or if the filter is damaged. If this is the case, also check that the impeller sensor is not dirty or

damaged. Clean the sensor (do not use compressed air) and, if it is damaged, replace it.

X

18

Open the gas isolator cock, reconnect the product to the mains and switch it on.

X

X

19

If the automatic purging programme does not start, open the service valves, fill the product

or the heating installation to 0.1-0.2 MPa/1.0-2.0 bar (depending on the static height of the

heating installation) and manually start the purging programme

P.07

.

X

20

Perform a test operation of the product and heating installation, including hot water generation

(if available), and purge the system once more if necessary.

X

X

21

Check the CO

₂

content (the air ratio) of the product again.

X

22

Ensure that no gas, flue gas, water or condensate is leaking from the product. Restore leak-

tightness if necessary.

X

X

23

Record the inspection/maintenance work carried out.

X

X

*Note: For those appliances which are not part of an annual service agreement/policy, maintenance must be carried out at least every

5 years.

Содержание home combi

Страница 51: ......