11

ecoTEC plus 937 installation and maintenance manual

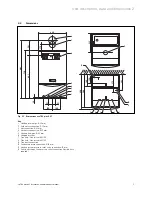

The ecoTEC plus 937 is a fully-automatic wall-mounted

unit with condensing technology for central heating and

hot water preparation and with a shift load storage tank

for the storage of hot water.

Mains cold water heated by the combi boiler is fed to the

heat insulated storage tank by means of a modulating

storage tank charging pump.

The provision of hot water takes place directly from the

combi boiler without the need for a copper cylinder, a

cold water tank or a supply and expansion vessel with

the corresponding pipework. The provision of hot water

has priority over the central heating.

The combi unit supplies the shift load storage tank with

electrical energy for the storage tank charging pump.

The combi unit is equipped with a warm start function

which keeps the heat exchanger hot so that hot water is

immediately available.

The temperature in the hot water heat exchanger is

limited by the control system.

Fitting a water softener on the mains cold water inlet of

the combi boiler is not necessary. In regions with

extremely hard water (greater than 300 mg/l of CaCO

3

)

however a water softener may still be fitted in order to

prevent the formation of scale build up in the water

pipes.

The heating system can be filled using the filling devices

fitted to the ecoTEC plus combination boilers.

The ecoTEC plus 937 is be supplied for natural gas and

can be converted for propane gas with a conversion kit.

3 General

requirements

3.1

Preliminary remarks for room sealed

appliances

This appliance should only be installed in conjunction

with either a Vaillant flue system or an alternative

approved system (details of flue approval categories can

be found in the technical section of the installation

manual).

Install the flue system as detailed in the separate flue

installation instructions supplied with this boiler.

3.2 Related

documents

The installation of the boiler must be in accordance with

the relevant requirements of Gas Safety (Installation and

Use) Regulations 1998, Health and Safety Document No.

635 (The Electricity at Work Regulations 1989), BS 7671

(IEE Wiring Regulations) and the Water Supply (Water

Fitting) Regulations 1999, or The Water Bylaws 2000

(Scotland). It should also be in accordance with the

relevant requirements of the Local Authority, Building

Regulations, The Building Regulations (Scotland), The

Building Regulations (Northern Ireland) and the relevant

recommendations of the following British Standards:

BS 6700: Services supplying water for domestic use

within buildings and their curtilages.

BS 6798: Specification for installation of gas fired

boilers not exceeding 60 kW input.

BS 6891: Specification for installation of low pressure

gas pipework up to 28 mm (R1) in domestic premises

(2nd family gas).

BS 7593: Treatment of water in domestic hot water

central heating systems. – Institute of Gas Engineers

Publication IGE/UP/7/1998: ”Guide for gas installations

in timber framed housing”

BS 5482: Pt. 1 Domestic butane and propane gas burning

installations.

IGE/UP1: Soundness testing and purging of industrial and

commercial gas installation.

IGE/UP2: Gas installation pipework, boosters and

compressors on industrial and commercial premises.

IGE/UP10. Installation of gas appliances in industrial and

commercial premises.

BS 6644: Installation of gas fired hot water boilers of

rated inputs between 60 kW and 2 MW (2nd and 3rd

family gases).

BS 5449: Forced circulation hot water central heating

systems for domestic premises. Note: only up to 45 kW.

BS 6880: Low temperature hot water heating systems of

output greater than 45 kW.

Part 1 Fundamental and design considerations.

Part 2 Selection of equipment.

Part 3 Installation, commissioning and maintenance.

BS 4814: Specification for: Expansion vessels using an

internal diaphragm, for sealed hot water heating

systems.

BS 5440: Installation and maintenance of flues and

ventilation for gas appliances of rated input not

exceeding 70 kW net (1st, 2nd and 3rd family gases).

Part 1 Specification for installation of flues.

Part 2 Specification for installation and

maintenance of ventilation for gas appliances.

European installation directive

a

Caution!

Installation and maintenance of the unit may

only be undertaken by a competent person in

accordance with the "Gas Safety (Installation

and Use) Regulations 1998".

In IE the installation must comply with the

current Version of I.S.813 ‘Domestic Gas

Installations’ and the current Building

Regulations. The current ETCI Regulations for

the installation of electrical equipment must

also be observed.

Caution!

To tighten or loosen bolts, only use suitable

open-ended spanners (do not use wrenches or

extensions etc.).

Improper use or unsuitable tools can cause

damage, (such as gas or water leaks.)

Unit description, data and dimensions 2

General requirements 3