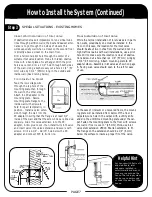

Measuring: Measurements should be taken from the

base of the pipe-stop, which is on the inside of the fit-

ting hub. As each section of tubing is cut, it should be

dry fitted before the next measurement is taken.

Cutting: The tubing must be cut as straight and square

as possible. A miter box should be used if available. All

rough edges must be removed with a utility knife or

coarse sandpaper.

Dry Fitting: Once all the pieces are cut, they should be

dry fitted to check for correct fit. The markings on the

fittings can be utilized to assure proper alignment.

Gluing: PVC solvent cement actually welds the fitting to

the tubing. A chemical reaction permanently joins the

molecules from each surface to produce an airtight seal.

Before cementing, both the tubing and the fitting must

be free of PVC burrs, dirt, and grime. The components

should be wiped with a clean cloth if necessary. Cement

should only be applied to the tubing because cement

applied to the fitting will be pushed ahead and create a

rough bead on the inside of the fitting. This bead will

reduce airflow and could cause a clog. The tubing

should be inserted all the way into the fitting and

twisted a quarter turn to evenly distribute the cement.

All excess cement should be removed with a rag. The

glue should be allowed to set for several hours before

the vacuum system is used.

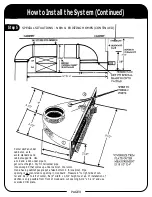

Every power unit has an on/off switch that is activated

by completing a circuit at the inlet valves. The power

unit is turned on by simply inserting the hose in the

inlet valve. To facilitate this, low voltage wire must fol-

low the tubing system. At the junction of a branch line

and the trunk line, the wires must be spliced together.

Each inlet valve must be able to activate the machine

independently of the other valves. There must be an

uninterrupted route from each inlet valve to the power

unit. With wire ties, attach the wire to the tubing at

least every four feet. If using Lexan inlet valves, do not

loop wires at valve locations. Only one pair of wires

can be hooked up to these valves.

HOW TO CUT AND CEMENT PVC TUBING AND FITTINGS

LOW VOLTAGE WIRE

PAGE 4

Planning the Central Vacuum System (Continued)