(10)

♦

♦

♦

♦

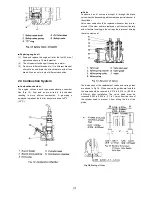

Boring and replacing the cylinder liner

Referring to Fig. 22, the inside diameter of the liner

should be checked at points 1, 2, and 3 and in the

directions (a) and (b). The liner on which the wear has

exceeded the service limit can be bored and honed to

0.020 in (0.50mm) oversize. The finished dimensions

are 3.012 to 3.013 in: (76.500 to 76.519mm) Models

5416 and 5424.

An oversized piston and rings must then he used with

this liner. Once this oversized liner has exceeded its

wear limit, it should be replaced with a new one. To

install a new liner, coat the outside liberally with oil,

push into the block with a press and finish to the

standard Size. When this is done, a standard size

piston must again be used.

♦

♦

♦

♦

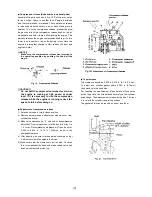

Tightening Cylinder Head Capscrews (Fig. 23)

(1) The tightening torque of the cylinder head

capscrews is 54 to 58 ft.lbs. (7.5 to 8.0 kg.m).

Numbers 7, 8, 11 and 13 (

♦

♦

♦

♦

)

are studs. The nuts on

these studs should also be tightened to this torque.

(2) All the capscrews must be tightened uniformaly. To do

this, tighten all the capscrews in the order indicated on

the diagram until they are just snug. Then tighten each

one (1) turn at a time in this same sequence until all

have been tightened to the required torque.

(3) The cylinder head capscrews should be re-tightened if

the engine has not been used for a long time. The valve

lash should also be adjusted each time the cylinder

head capscrews are retorqued. If the cylinder head

gasket has been replaced, run the engine for about 30

minutes and re-tighten the cylinder head capscrews as

described above.

Содержание Universal diesel 5416

Страница 21: ...19...