(5)

♦

♦

♦

♦

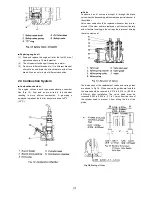

Fuel injection nozzle

The fuel injection nozzle, like the fuel injection pump, is also

a precision piece of equipment and should be treated with the

same amount of care.

♦

♦

♦

♦

The nozzle cracking pressure

The nozzle cracking pressure is adjusted by adding or

subtracting shims from the top of the nozzle spring. Adding a

0.004in. (0.1mm) shim will increase the cracking pressure by

about 142 psi. (10 kg/cm

2

). The nozzle cracking pressure is

1990 to 2133 psi. (140 to 150 kgf/cm

2

)

♦

♦

♦

♦

Spray pattern

The nozzle cracking pressure and fuel spray pattern are most

accurately checked by using a nozzle “pop test” stand. If a

“pop test” stand is not available, remove the nozzles from the

engine, leaving the pressure lines connected.

[[ CAUT ION ]]

Hold nozzles so that the high pressure spray from them

will not in any way impinge upon unprotected skin. The

atomized fuel will easily penetrate the skin and cause

blood poisoning.

Set the speed control lever at W. 0. T. and operate the

starter. The needle valve, if it is working properly, will

produce a high pitched pulsating sound like that of a flute as

fuel is sprayed out. If this sound is not heard or other

problems are noted, refer to the “Fuel Injection Pump &

Nozzle Maintenance Std.” in 4.1 in “Engine”.

[[ Precaution ]]

(1) Assembly and disassembly of the nozzle should be

done in fresh clean fuel

(2) The nozzle should always be installed as an

assembly, never by component parts

(3) Remember never to let the nozzle spray contact

unprotected flesh

(4) Tighten the retaining nut to 43.5 to 58 ft-lb (6 to 8

kgf.m) Any torque higher than this will cause slow

action of the needle valve and poor injection.

2.2 Lubrication System

♦

♦

♦

♦

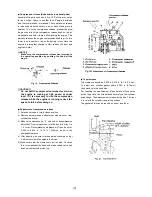

Oil pump pick-up screen

The oil pump pick-up is located in the crankcase as shown in

Fig. 9 and is fitted with a metal screen. If the screen becomes

plugged, wash it off with diesel fuel or kerosene.

♦

♦

♦

♦

Lubrication system

The entire lubrication system is illustrated in Fig. 8. Oil from

the pump is forced through the replaciable paper element

filter. The filter is equipped with a pressure regulated valve to

keep the pressure through the filter at 64— 71 psi. (4.5—5

kgf/cm

2

). From the filter part of the oil goes to the crankshaft

to lubricate the crankpins and the remainder goes to lubricate

the rocker arms.

An oil pressure switch is located in the passage from the filter

and controls the oil pressure. If the oil pressure falls below 14

psi. (1.0 kgf/cm

2

) the oil warning lamp will light on the dash

panel. If the oil pressure lamp stays on after the engine is

running at normal speed, shut the engine off immediately.

Find and correct the cause of the low oil pressure before

operating again.

If the pressure regulating valve in the filter fails and the

pressure rises, a safety valve will limit the pressure to 140

psi. (10 kgf/cm

2

)

Содержание Universal diesel 5416

Страница 21: ...19...