1.3 -

Pressure equipment and components

These products incorporate equipment or components under

pressure, manufactured by Carrier or other manufacturers. We

recommend that you contact your professional body to find out

which regulations affect you as the operator or owner of pressure

equipment or components (declaration, re-qualification, re-testing,

etc.). The characteristics of this equipment/these components are

given on the name plate or in the regulatory documentation

supplied with the products.

These units comply with the European Pressure Equipment

Directive.

The units are intended to be stored and operated in an

environment where the ambient temperature is always within

the allowable temperature range indicated on the nameplate.

Do not introduce significant static or dynamic pressure with

regard to the operating pressures used during operation, or

for tests in the refrigerant circuit or heat exchange circuits.

NOTE: Monitoring during operation, re-qualification, re-

testing and re-testing dispensation:

•

Follow regulations on the monitoring of pressure

equipment.

•

The user or the operator is usually required to create

and maintain a monitoring and maintenance register.

•

In the absence of any regulations, or in addition to the

regulations, follow the guidance in EN 378.

•

Follow the local professional recommendations,

whenever they exist.

•

Regularly inspect the surface of the components for

signs of corrosion. To do this, check an uninsulated

part of the component or check for an accumulation of

rust at the insulation joints.

•

Regularly check for the presence of any impurities (e.g.

sand, grit) in the heat transfer fluids. These impurities

can cause wear and/or pitting corrosion.

•

Install filters in the heat transfer fluid piping.

•

The reports from the regular checks carried out by the

user or operator must be included in the monitoring

and maintenance register.

Repair:

Any repair or modification of a pressurised container is

prohibited.

Only the replacement of the container with an original

manufacturer component is authorised. In this case, the

replacement must be carried out by a qualified operator.

The replacement of the vessel must be entered in the

monitoring and maintenance register.

Recycling:

The pressure equipment can be recycled in whole or in part.

After use, they may contain refrigerant vapours and oil

residue. Some parts are painted.

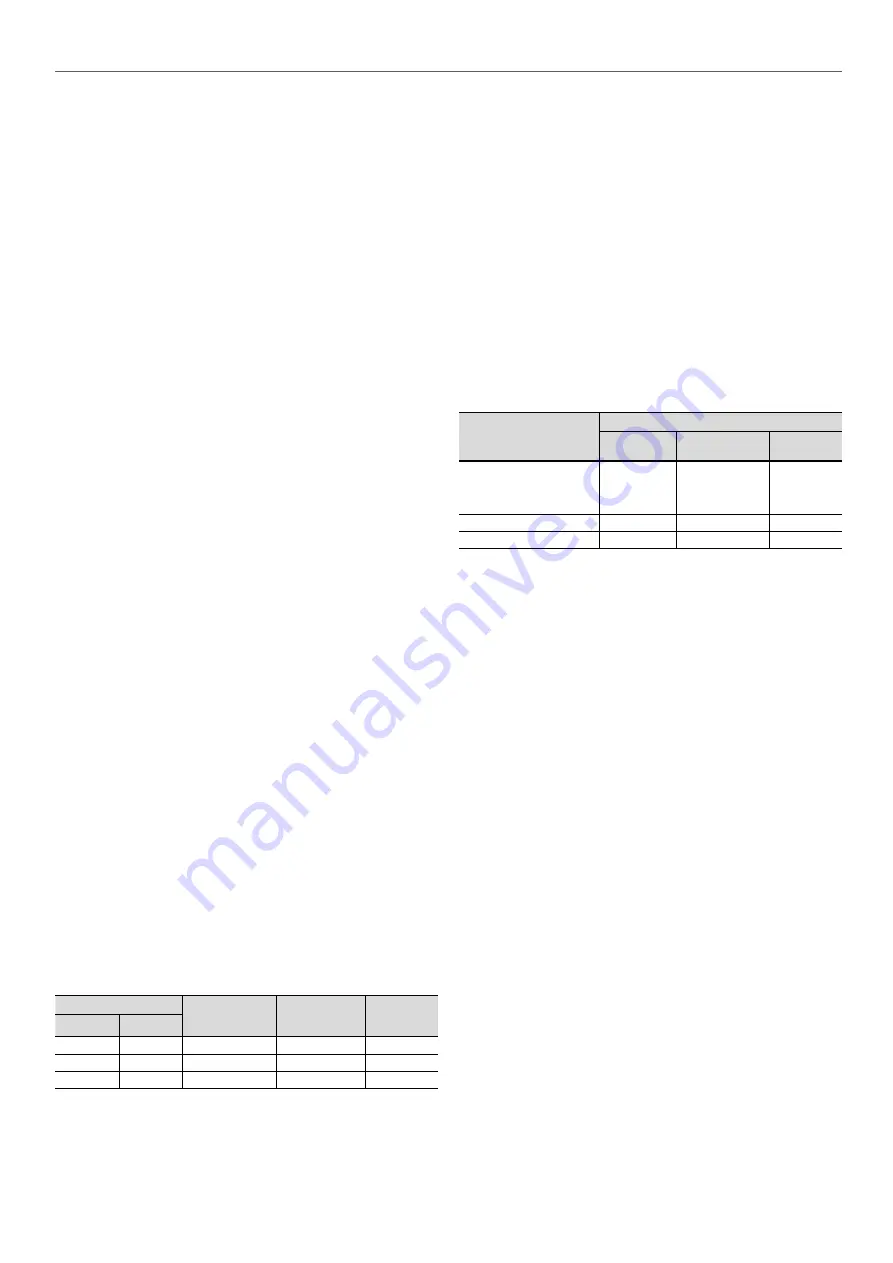

1.4 - Maintenance safety considerations

Carrier recommends the following table as a guide to completing

the monitoring and maintenance register (logbook) required by

EN 378-2:

Intervention

Name of the

commissioning

engineer

Applicable

national

regulations

Verification

Organism

Date

Nature

(1)

(1) Maintenance, repairs, regular verifications (EN 378), leakage, etc.

Engineers working on the electrical or refrigeration components

must be authorised, trained and fully qualified to do so. All work

on the refrigerant circuit must be carried out by a trained person,

fully qualified to work on these units. He/she must have been

specifically trained on this equipment and system. All welding

operations must be carried out by qualified specialists.

30RQM/30RQP units use high pressure R-410A refrigerant (the

unit operating pressure is above 40 bar; the pressure at an air

temperature of 35°C is 50% higher than for R-22). Special

equipment must be used when working on the refrigerant circuit

(pressure measurement, charge transfer, etc.).

Do not clean the unit with hot water or steam. This may cause

the refrigerant pressure to rise.

Any manipulation (opening or closing) of a shut-off valve

must be carried out by a qualified and authorised engineer,

observing applicable standards (e.g. during draining

operations). The unit must be switched off during maintenance.

NOTE: The unit must never be left shut down with the liquid

line valve closed, as liquid refrigerant can be trapped between

this valve and the expansion device and lead to the risk of a

pressure increase. This valve is situated on the liquid line

before the filter drier.

Equip the engineers that work on the unit as follows:

Personal protection

equipment (PPE)

(1)

Operations

Handling

Maintenance,

service

Welding or

brazing

(2)

Protective gloves,

eye protection,

safety shoe,

protective clothing.

X

X

X

Ear protection.

X

X

Filtering respirator.

X

(1) We recommend to follow the instructions in EN 378-3.

(2) Performed in the presence of A1 refrigerant according to EN 378-1.

Never work on a unit that is still energized.

Never work on any of the electrical components until the

general power supply to the unit has been isolated.

Lock the power supply circuit upstream of the unit in the open

position during maintenance interventions.

If work is interrupted for any reason, check that all circuits

are powered off before resuming work.

CAUTION: Even if the unit has been shut down, the power

circuit remains energized, unless the unit or circuit disconnect

switch is open. Refer to the wiring diagram for further details.

Follow the appropriate safety guidelines. When working on

the fan deck, particularly if the discharge grilles have been

removed, isolate the power supply to the fans to prevent their

operation.

CAUTION: The option Power factor (231) and the variable

frequency drives (VFD) fitted to the 30RQP units and the units

with options 116V, 116W or 28 have capacitor banks whose

discharge time is five (5) minutes after disconnecting the

power supply.

After disconnecting the power supply to the electrical box,

wait for 5 minutes before accessing the electrical box or

variable drives.

Before any intervention, verify that there is no voltage present

on any accessible conducting parts of the power circuit.

It is recommended that an indicating device be installed to

check if any refrigerant has leaked from the relief valve.

The presence of oil at the outlet orifice is a useful indicator

that refrigerant has leaked. Keep this orifice clean to ensure

that any leaks are obvious. The calibration of a valve that has

leaked is generally lower than its original calibration. The new

calibration may affect the operating range. To avoid nuisance

tripping or leaks, replace or re-calibrate the valve.

CAUTION: If refrigerant circuit service valves are installed,

ensure the protective caps are fitted in order to avoid

leakages.

1 - INTRODUCTION

5

Содержание Carrier 30RQM 160

Страница 63: ......