66832-UIM-D-1205

Unitary Products Group

27

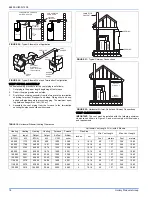

Input / Output / CFM / Cabinet Width (A=14-1/2, B=17-1/2, C=21, D=24-1/2)

Motor voltage is 115VAC.

TABLE 18: Blower Performance - CFM

UPFLOW, SINGLE SIDE RETURN (WITHOUT FILTER)

BTU/H (kW)

Input / Output

Cabinet

Size

Speed

Tap

EXTERNAL STATIC PRESSURE, INCHES WC (kPa)

0.1 (0.025)

0.2 (0.050)

0.3 (0.075)

0.4 (0.099)

0.5 (0.124)

0.6 (0.149)

0.7 (0.174)

0.8 (0.199)

cfm cm/m

cfm cm/m

cfm cm/m

cfm cm/m

cfm cm/m

cfm cm/m

cfm cm/m

cfm cm/m

50/40 (14.7/11.7)

1

B

High

1411

40.0

1360

38.5

1289

36.5

1218

34.5

1154

32.7

1075

30.4

983

27.8

882

25.0

Med

1213

34.3

1177

33.3

1134

32.1

1085

30.7

1022

28.9

960

27.2

880

24.9

782

22.1

Low

887

25.1

884

25.0

871

24.7

848

24.0

814

23.0

775

21.9

726

20.6

656

18.6

75/60 (22.0/17.6)

1

B

High

1535

43.5

1470

41.6

1408

39.9

1343

38.0

1275

36.1

1202

34.0

1115

31.6

1014

28.7

Med

1215

34.4

1199

34.0

1182

33.5

1151

32.6

1106

31.3

1039

29.4

976

27.6

887

25.1

Low

875

24.8

874

24.7

864

24.5

847

24.0

827

23.4

799

22.6

736

20.8

658

18.6

75/60 (22.0/17.6)

1

C

High

1792

50.7

1724

48.8

1630

46.2

1552

43.9

1462

41.4

1367

38.7

1264

35.8

1152

32.6

Med

1597

45.2

1555

44.0

1496

42.4

1444

40.9

1372

38.9

1287

36.4

1190

33.7

1086

30.8

Low

1115

31.6

1140

32.3

1167

33.0

1183

33.5

1149

32.5

1093

31.0

1023

29.0

939

26.6

100/80 (29.3/23.4)

1

C

High

1868

52.9

1781

50.4

1690

47.9

1600

45.3

1498

42.4

1396

39.5

1277

36.2

1156

32.7

Med

1602

45.4

1553

44.0

1503

42.6

1447

41.0

1376

39.0

1287

36.4

1181

33.4

1060

30.0

Low

1147

32.5

1147

32.5

1147

32.5

1147

32.5

1132

32.1

1078

30.5

1009

28.6

918

26.0

100/80 (29.3/23.4)

2

D

High

NOT ALLOWED

Med-High

Med-Low

Low

125/100(36.6/29.3)

3

D

High

Med-High

Med-Low

Low

150/120(44.0/35.2)

2

D

High

Med-High

Med-Low

Low

DUAL RETURN (TWO SIDES OR ONE-SIDE & BOTTOM)

50/40 (14.7/11.7)

1

B

High

1507

42.7

1433

40.6

1371

38.8

1300

36.8

1223

34.6

1132

32.1

1040

29.4

938

26.6

Med

1239

35.1

1215

34.4

1175

33.3

1144

32.4

1085

30.7

1012

28.7

938

26.6

838

23.7

Low

907

25.7

907

25.7

891

25.2

875

24.8

849

24.0

800

22.7

741

21.0

672

19.0

75/60 (22.0/17.6)

1

B

High

1634

46.3

1562

44.2

1484

42.0

1417

40.1

1340

37.9

1238

35.1

1154

32.7

1030

29.2

Med

1243

35.2

1228

34.8

1214

34.4

1184

33.5

1133

32.1

1079

30.6

999

28.3

912

25.8

Low

886

25.1

886

25.1

886

25.1

886

25.1

865

24.5

823

23.3

777

22.0

700

19.8

75/60 (22.0/17.6)

1

C

High

1978

56.0

1896

53.7

1803

51.1

1693

47.9

1589

45.0

1478

41.9

1366

38.7

1235

35.0

Med

1682

47.6

1657

46.9

1606

45.5

1530

43.3

1455

41.2

1366

38.7

1265

35.8

1137

32.2

Low

1235

35.0

1235

35.0

1235

35.0

1235

35.0

1198

33.9

1154

32.7

1083

30.7

987

27.9

100/80 (29.3/23.4)

1

C

High

2122

60.1

2027

57.4

1916

54.3

1821

51.6

1717

48.6

1590

45.0

1462

41.4

1312

37.2

Med

1667

47.2

1696

48.0

1656

46.9

1597

45.2

1523

43.1

1438

40.7

1330

37.7

1191

33.7

Low

1130

32.0

1145

32.4

1177

33.3

1194

33.8

1181

33.4

1146

32.5

1077

30.5

982

27.8

100/80 (29.3/23.4)

2

D

High

2350

66.5

2248

63.7

2129

60.3

2015

57.1

1876

53.1

1745

49.4

1596

45.2

1425

40.4

Med-High

2122

60.1

2018

57.1

1926

54.5

1824

51.6

1722

48.8

1606

45.5

1458

41.3

1311

37.1

Med-Low

1958

55.4

1875

53.1

1782

50.5

1690

47.9

1608

45.5

1491

42.2

1364

38.6

1213

34.3

Low

1820

51.5

1757

49.8

1664

47.1

1594

45.1

1506

42.6

1405

39.8

1287

36.4

1137

32.2

125/100(36.6/29.3)

2

D

High

2483

70.3

2392

67.7

2282

64.6

2161

61.2

2032

57.5

1887

53.4

1739

49.2

1567

44.4

Med-High

2198

62.2

2123

60.1

2039

57.7

1930

54.7

1830

51.8

1708

48.4

1550

43.9

1413

40.0

Med-Low

1999

56.6

1916

54.3

1859

52.6

1778

50.3

1684

47.7

1576

44.6

1451

41.1

1315

37.2

Low

1832

51.9

1775

50.3

1709

48.4

1642

46.5

1556

44.1

1450

41.1

1335

37.8

1209

34.2

150/120(44.0/35.2)

2

D

High

2570

72.8

2462

69.7

2361

66.9

2244

63.5

2128

60.3

1983

56.2

1826

51.7

1655

46.9

Med-High

2205

62.4

2105

59.6

2033

57.6

1952

55.3

1865

52.8

1738

49.2

1617

45.8

1459

41.3

Med-Low

1993

56.4

1931

54.7

1869

52.9

1880

53.2

1708

48.4

1590

45.0

1485

42.1

1330

37.7

Low

1831

51.8

1782

50.5

1722

48.8

1660

47.0

1575

44.6

1477

41.8

1364

38.6

1231

34.9

BOTTOM/END RETURN

50/40 (14.7/11.7)

1

B

High

1419

40.2

1357

38.4

1297

36.7

1212

34.3

1131

32.0

1050

29.7

942

26.7

846

24.0

Med

1221

34.6

1185

33.6

1145

32.4

1092

30.9

1036

29.3

961

27.2

879

24.9

780

22.1

Low

920

26.1

902

25.5

883

25.0

860

24.4

818

23.2

761

21.5

711

20.1

639

18.1

75/60 (22.0/17.6)

1

B

High

1552

43.9

1491

42.2

1420

40.2

1348

38.2

1271

36.0

1185

33.6

1080

30.6

970

27.5

Med

1229

34.8

1237

35.0

1198

33.9

1164

33.0

1105

31.3

1039

29.4

956

27.1

861

24.4

Low

889

25.2

892

25.3

879

24.9

866

24.5

846

24.0

807

22.9

760

21.5

689

19.5

75/60 (22.0/17.6)

1

C

High

1946

55.1

1862

52.7

1775

50.3

1620

45.9

1518

43.0

1409

39.9

1291

36.6

1160

32.8

Med

1683

47.7

1611

45.6

1551

43.9

1484

42.0

1388

39.3

1300

36.8

1190

33.7

1080

30.6

Low

1110

31.4

1138

32.2

1175

33.3

1190

33.7

1175

33.3

1126

31.9

1041

29.5

937

26.5

100/80 (29.3/23.4)

1

C

High

1997

56.5

1920

54.4

1822

51.6

1723

48.8

1620

45.9

1500

42.5

1355

38.4

1211

34.3

Med

1728

48.9

1679

47.5

1635

46.3

1556

44.1

1465

41.5

1359

38.5

1249

35.4

1117

31.6

Low

1131

32.0

1156

32.7

1181

33.4

1190

33.7

1171

33.2

1126

31.9

1049

29.7

926

26.2

100/80 (29.3/23.4)

2

D

High

2327

65.9

2232

63.2

2121

60.1

1999

56.6

1888

53.5

1763

49.9

1628

46.1

1473

41.7

Med-High

2050

58.0

1967

55.7

1868

52.9

1757

49.8

1658

46.9

1525

43.2

1403

39.7

1260

35.7

Med-Low

1911

54.1

1839

52.1

1758

49.8

1675

47.4

1593

45.1

1468

41.6

1340

37.9

1189

33.7

High

1780

50.4

1712

48.5

1642

46.5

1566

44.3

1465

41.5

1366

38.7

1249

35.4

1094

31.0

125/100(36.6/29.3)

2

D

High

2397

67.9

2304

65.2

2192

62.1

2063

58.4

1955

55.4

1822

51.6

1678

47.5

1521

43.1

Med-High

2151

60.9

2063

58.4

1977

56.0

1881

53.3

1774

50.2

1652

46.8

1528

43.3

1377

39.0

Med-Low

1972

55.8

1906

54.0

1838

52.0

1748

49.5

1660

47.0

1551

43.9

1419

40.2

1282

36.3

Low

1845

52.2

1794

50.8

1721

48.7

1646

46.6

1559

44.1

1451

41.1

1344

38.1

1208

34.2

150/120(44.0/35.2)

2

D

High

2488

70.5

2389

67.6

2276

64.4

2151

60.9

2024

57.3

1883

53.3

1730

49.0

1577

44.7

Med-High

2164

61.3

2084

59.0

2024

57.3

1920

54.4

1816

51.4

1692

47.9

1558

44.1

1395

39.5

Med-Low

1998

56.6

1934

54.8

1868

52.9

1773

50.2

1673

47.4

1567

44.4

1445

40.9

1294

36.6

Low

1843

52.2

1793

50.8

1728

48.9

1653

46.8

1553

44.0

1453

41.1

1328

37.6

1192

33.8

1.

Return air is through side opposite motor (left side)

.

2. Airflows above 1800 CFM (50.97 m3/min) require either return from two sides or one side plus bottom

3. Airflows expressed in standard cubic feet per minute (CFM) and in cubic meters per minute (m

3

/min).