66832-UIM-D-1205

10

Unitary Products Group

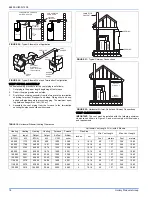

SIDE RETURN/BOTTOM EXTERNAL INSTALLATION

Locate and knock out the square corner locators. These indicate the

size of the cutout to be made in the furnace side panel. Refer to Figure 9.

Install the side filter rack following the instructions provided with that

accessory. If a filter(s) is provided at another location in the return air

system, the ductwork may be directly attached to the furnace side

panel. An accessory filter rack is available for mounting the filter exter-

nal to the cabinet.

Some accessories such as electronic air cleaners and pleated media

may require a larger side opening. Follow the instructions supplied with

that accessory for side opening requirements. Do not cut the opening

larger than the dimensions shown in Figure 5.

EXTERNAL INSTALLATION FOR

UPFLOW/HORIZONTAL CONFIGURATIONS

1.

Select desired filter position for upflow/horizontal (left/right side,

side and bottom). Remove the corresponding cabinet cutouts per

instructions provided.

2.

Install the external filter box to the side of the cabinet and secure

to the cabinet as specified in the instructions provided with the air

filter kit. If a side return is to be used, cut out the side of the casing

14" high by 16 1/4" wide using the lances in the casing side as a

guide. DO NOT CUT THE OPENING LARGER THAN 14" X 16 1/

4". It is not permissible to cut out the back of the furnace. For bot-

tom returns you place the external filter box between the return air

plenum and the base of the furnace. The casing bottom is

embossed to indicate where to bend the flanges. Refer to Figure 5

for the maximum return air opening sizes. Seal this connection to

prevent leaks.

Do not cut the opening larger than the dimensions shown in Figure

5.

3.

Install the return air duct to the air filter box and secure with

screws. Seal this connection to prevent leaks.

4.

Install the field provided filter. Refer to Table 5 for the recom-

mended filter size for your furnace.

NOTE: Air velocity must not exceed 300 feet per minute through low

velocity disposable filters. Air velocity must not exceed 650 feet

per minute through high velocity cleanable permanent filters.

Use of a filter that is too small will cause static pressure in the

duct system to be too high, which will have an adverse effect on

heating and cooling operation.

Downflow Filters

Downflow furnaces typically are installed with the filters located above

the furnace, extending into the return air plenum or duct. Any branch

duct (rectangular or round duct) attached to the plenum must attach to

the vertical plenum above the filter height. Refer to Figure 11 for proper

installation.

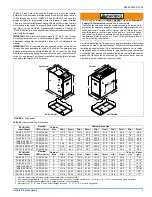

TABLE 5: Filter Sizes - Upflow

UPFLOW

Cabinet

Size

Side

Return

Bottom/End

Return

Input

Output

Air Flow

MBH

kW

MBH

kW

CFM

cmm

in.

cm

in.

cm

50

14.7

40

11.7

1200

34.0

B

25 x 16

64 x 41

24 x 15

61 x 38

75

22.0

60

17.6

1200

34.0

B

25 x 16

64 x 41

24 x 15

61 x 38

75

22.0

60

17.6

1600

45.3

C

25 x 16

64 x 41

24 x 18

61 x 46

100

29.3

80

23.4

1600

45.3

C

25 x 16

64 x 41

24 x 18

61 x 46

100

29.3

80

23.4

2000

56.6

D

(2) 25 x 16

(2) 64 x 41

24 x 21

61

125

36.6

100

29.3

2000

56.6

D

(2) 25 x 16

(2) 64 x 41

24 x 21

61

150

44.0

120

35.2

2000

56.6

D

(2) 25 x 16

(2) 64 x 41

24 x 21

61

DOWNFLOW

Top Return (Downflow)

Cleanable Air Filters

Top Return (Downflow)

Disposable Air Filters

Input

Output

Air Flow

Cabinet Size

MBH

kW

MBH

kW

CFM

cmm

in.

cm

in.

cm

50

14.7

40

11.7

1200

34.0

B

14 x 20

(2) 25 x 51

(2) 10 x 20

(2) 25 x 51

75

22.0

60

17.6

1200

34.0

B

14 x 20

(2) 36 x 51

(2) 14 x 20

(2) 36 x 51

75

22.0

60

17.6

1600

45.3

C

16 x 20

(2) 41 x 51

16 x 20

(2) 41 x 51

100

29.3

80

23.4

1600

45.3

C

16 x 20

(2) 41 x 51

16 x 20

(2) 41 x 51

100

29.3

80

23.4

2000

56.6

D

20 x 20

(2) 51 x 51

20 x 20

(2) 51 x 51

125

36.6

100

29.3

2000

56.6

D

20 x 20

(2) 51 x 51

20 x 20

(2) 51 x 51

150

44.0

120

35.2

2000

56.6

D

N/A

N/A

N/A

N/A

FIGURE 9: Side Return Cutout Markings

CORNER

MARKINGS

FRONT OF

FURNACE

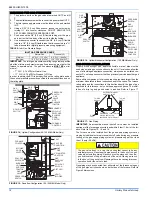

FIGURE 10: Horizontal Mount and Filter

FIGURE 11: Downflow Filter

FURNACE

RETURN

DUCT

18”

MIN.

AIR

FILTER

FILTER RACK

RACK AND FILTERS SECURED

INSIDE BLOWER SECTION

FOR SHIPMENT

DUCTWORK

FILTERS

BRANCH

DUCTS

FH

CROSS SECTION A-A

(with Plenum and filters)

FILTER

RACK

NOTE: FILTER ACCESS THROUGH

DUCTWORK MUST BE PROVIDED

FOR REMOVAL AND CLEANING

CASING SIZE DIMENSION FH

16-1/4”

22-1/4”

26-1/4”

12-3/4”

11”

8-1/4”