66832-UIM-D-1205

Unitary Products Group

25

IMPORTANT: The inlet gas pressure operating range table specifies

what the minimum and maximum gas line pressures must be for the fur-

nace to operate safely. The gas line pressure MUST BE a minimum of

•

7” W.C. (1.74 kPA) for Natural Gas

•

11” W.C. (2.74 kPA) for Propane (LP) Gas

in order to obtain the BTU input specified on the rating plate and in

these instructions.

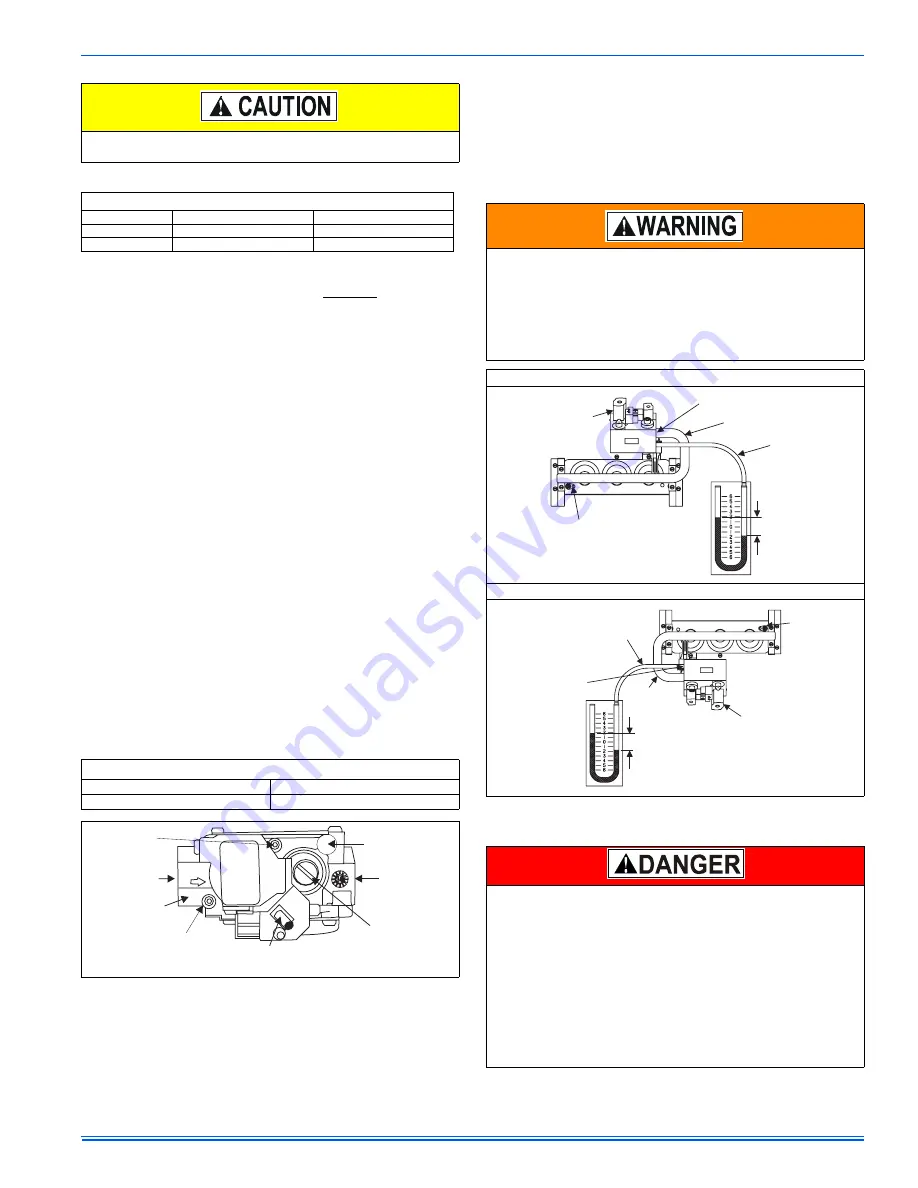

ADJUSTMENT OF MANIFOLD GAS PRESSURE

Manifold gas pressure may be measured at the gas valve.

Turn gas off at the ball valve or gas cock on gas supply line

before the gas valve. Find the pressure ports on the gas

valve marked OUT P and IN P.

1.

The manifold pressure must be taken at the port marked OUT P.

2.

The gas line pressure must be taken at the port marked IN P.

3.

Using a 3/32” Allen wrench, loosen the setscrew by turning it 1

turn counter clockwise. DO NOT REMOVE THE SET SCREW

FROM THE PRESSURE PORT.

4.

Use the 4” (10.2 cm) piece of 1/8” (0.3 cm) tubing to connect the

positive side of the manometer to the gas valve pressure refer-

ence port. Refer to Figure 38 for connection details.

IMPORTANT: The cap for the pressure regulator must be removed

entirely to gain access to the adjustment screw. Loosening or tightening

the cap does not adjust the flow of gas.

5.

Refer to Figure 37 for location of pressure regulator adjustment

cap and adjustment screw on main gas valve.

6.

Turn gas and electrical supplies on and follow the operating

instructions to place the unit back in operation.

7.

Adjust manifold pressure by adjusting gas valve regulator screw

for the appropriate gas per the following:

IMPORTANT: If gas valve regulator is turned in (clockwise), manifold

pressure is increased. If screw is turned out (counterclockwise), mani-

fold pressure will decrease.

8.

After the manifold pressure has been adjusted, re-calculate the

furnace input to make sure you have not exceeded the specified

input on the rating plate. Refer to “CALCULATING THE FURNACE

INPUT (NATURAL GAS)”.

9.

Once the correct BTU (kW) input has been established, turn the

gas valve to OFF and turn the electrical supply switch to OFF; then

remove the flexible tubing and fittings from the gas valve pressure

tap and tighten the pressure tap plug using the 3/32” Allen wrench.

10. Turn the electrical and gas supplies back on, and with the burners

in operation, check for gas leakage around the gas valve pressure

port for leakage using an approved gas detector, a non-corrosive

leak detection fluid, or other leak detection methods.

ADJUSTMENT OF TEMPERATURE RISE

Be sure to relight any gas appliances that were turned off at the

start of this input check.

TABLE 15: Inlet Gas Pressure Range

INLET GAS PRESSURE RANGE

Natural Gas

Propane (LP)

Minimum

4.5” W.C. (1.12 kPa)

8.0” W.C. (1.99 kPa)

Maximum

10.5” W.C. (2.61 kPa)

13.0” (3.24 kPa) W.C.

TABLE 16: Nominal Manifold Pressure

NOMINAL MANIFOLD PRESSURE

Natural Gas

3.5" w.c. (0.87 kPa)

Propane (LP) Gas

10.0" w.c. (2.488 kPa)

FIGURE 37: Gas Valve

INLET

WRENCH

BOSS

INLET

PRESSURE

PORT

ON

OFF

ON/OFF SWITCH

(Shown in ON position)

MAIN REGULATOR

ADJUSTMENT

OUTLET

OUTLET

PRESSURE

PORT

VENT PORT

The manifold pressure must be checked with the screw-off cap for

the gas valve pressure regulator in place. If not, the manifold pres-

sure setting could result in an over-fire condition. A high manifold

pressure will cause an over-fire condition, which could cause pre-

mature heat exchanger failure. If the manifold pressure is too low,

sooting and eventual clogging of the heat exchanger could occur.

Be sure that gas valve regulator cap is in place and burner box to

gas valve pressure reference hose is connected.

MAINFOLD PRESSURE “U” TUBE CONNECTION

MAINFOLD PRESSURE “U” TUBE CONNECTION

FIGURE 38: Reading Gas Pressure

The temperature rise, or temperature difference between the return

air and the supply (heated) air from the furnace, must be within the

range shown on the furnace rating plate and within the application

limitations shown in Table 8 “ELECTRICAL AND PERFORMANCE

DATA”.

The supply air temperature cannot exceed the “Maximum Supply

Air Temperature” specified in these instructions and on the fur-

nace rating plate. Under NO circumstances can the furnace be

allowed to operate above the Maximum Supply Air Temperature.

Operating the furnace above the Maximum Supply Air Temperature

will cause premature heat exchanger failure, high levels of Carbon

Monoxide, a fire hazard, personal injury, property damage, and/or

death.

GAS VALVE

U-TUBE

MANOMETER

3.5 IN

WATER

COLUMN

GAS

PRESSURE

SHOWN

MANIFOLD PIPE

1/4” TUBING

FLAME

SENSOR

OUTLET

PRESSURE TAP

GAS VALVE

U-TUBE

MANOMETER

3.5 IN

WATER

COLUMN

GAS

PRESSURE

SHOWN

MANIFOLD

PIPE

1/4” TUBING

FLAME

SENSOR

OUTLET

PRESSURE

TAP