XP

22

12.0 Troubleshooting

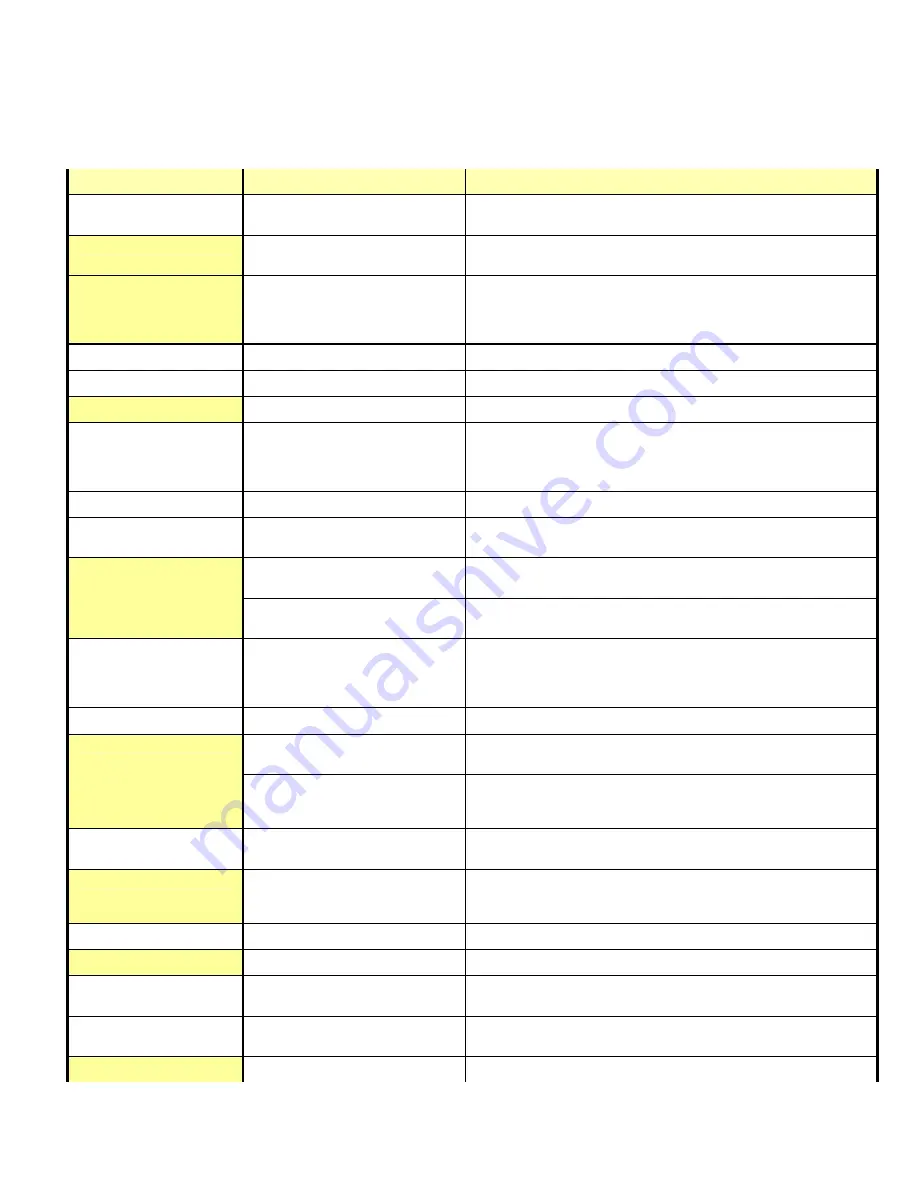

12.1 Basic Scenario Failure Analysis

The following table describes typical fault scenarios that may occur, the possible causes, and corrective actions to be taken.

Scenario

Possible Cause

Corrective Action

Burst Failure

Stock damaged and could not

burst/separate

Remove stock from burst area and press RESET key to continue

Stock length setting does not match stock

being used

Check with CRS or Airline host and confirm stock length setting

Burst positioning needs adjustment

Check the burst position level for the selected bin (in adjustments menu and listed

on configuration coupon). Adjust if appropriate (more +pos number moves burst

position further into the transport mechanism, while a more –neg number moves

the burst position towards the bin input.

Bin C will not load stock

Bin C is exposed to direct sunlight

Reposition the Unit so direct sunlight does not shine into the Bin C input.

Encode Error

Magnetic stock not loaded

Load magnetic stock in selected bins

Stock loaded in the wrong direction

Load stock correctly (confirm magnetic stripe location is against the inside wall)

Not powering up properly or

stuck in self-test state

Unit may have a hardware failure on the

transport mechanism PCBA (Printed

Circuit Board Assembly)

Toggle the Unit’s power switch to the

O

(OFF) position, wait a few seconds, then

switch the power switch to the

I

(ON) position and attempt to power on again. If

this does not correct the problem, call the CRS or Airline host Help Desk for

assistance

Out of Forms

One of the selected bins is out of stock.

Load more ticket stock in the selected bins

Not Operating

(display indicates Offline)

The Unit is off-line or the ONLINE key

was pressed while Unit was on-line.

Press the ONLINE key to place the Unit on-line

Paper jam in transport mechanism or ticket

stock path

Clear the jam and load the ticket stock correctly. Refer to the “Clearing Ticket

Jams” section for instructions

Host system has detected an error

condition and has taken the Unit off-line

Most errors can be corrected by pressing the RESET key, or restarting the Unit. If

problems persist, call the CRS or Airline host Help Desk for assistance

Not Operating

(display shows erroneous

characters)

Unit may have a hardware failure on the

transport mechanism PCBA (Printed

Circuit Board Assembly)

Toggle the Unit’s power switch to the

O

(OFF) position, wait a few seconds, then

switch the power switch to the

I

(ON) position and attempt to power on again. If

this does not correct the problem, call the CRS or Airline host Help Desk for

assistance

Not Operating (display is blank)

The Unit is not powered on.

Toggle the Unit’s power switch to the

I

(ON) position

Power line fuse may have blown or power

line circuit breaker may have tripped

Check the fuse or breaker protecting the power line going to the wall outlet used

to power the Unit. If OK, verify the wall outlet has power

The Unit’s power supply may have

malfunctioned, or a printed circuit board

may be defective

Make sure power cable(s) are plugged in and completely seated on both the wall

outlet and Unit ends. If this does not correct the problem, call the CRS or Airline

host Help Desk for assistance

Not Printing

(ONLINE LED does not blink)

The host is not communicating with the

Unit

Make sure that the host communication cable is connected and completely seated

on the Unit

The required hardware connection has not

been made or has been misconnected

Check the host connection and verify that the correct one has been installed. For

example, if using the serial RS-232 ports, make sure the cable is connected to

COMM1 and not COMM2 by mistake (some versions may use COMM2)

Not Printing on Ticket

Ticket stock loaded incorrectly

Load ticket stock in correct orientation

Using thermal transfer (TT) ticket stock

Load direct thermal (DT) ticket stock

Not printing in correct location

on the ticket

Print misalignment

Call the CRS or Airline host help desk for assistance

Print too Light or Dark

Print contrast level is too low for the stock

being used

Check the print contrast level for the selected bin (in adjustments menu and listed

on configuration coupon). Adjust if appropriate

Print head location misadjusted

Call the CRS or Airline Host help desk for assistance