CIB UNIGAS - M039177CA

6

How to interpret the burner’s “Performance curve”

To check if the burner is suitable for the boiler to which it must be installled, the following parameters are needed:

z

fuel

z

furnace input, in kW or kcal/h (kW = kcal/h / 860);

z

boiler type;

z

combustione head type (reverse flame or three phase)’

z

temperature or pressure of the thermal carrier fluid

z

Comburent air temperature

z

Air duct positioning

z

Pressure in the combustion chamber

z

Elevation (altitude) of burner installation

z

Gas train (only for gas burners)

z

Pumping unit (only for light-oil or heavy-oil burners)

z

Air fan

z

Bilt-in or separated control panel

z

backpressure (data are available on the boiler’s ID plate or in the user’s manual).

Burners provided with built-in control panel are designed for IP40 index of protection. For other values of IP, please contact the CIB

UNIGAS Technical Dpt.

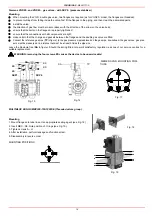

See the diagram in Fig. 2, as to find the burners that better suite the power range requested in the exmple (9600kW). Once the models

are founded out, the choice regards technical and economical features.

Checking the proper gas train size

To check the proper gas train size, it is necessary to the available gas pressure value upstream the burner’s gas valve. Then subtract

the backpressure. The result is called p

gas.

Draw a vertical line matching the furnace input value (600kW, in the example), quoted on

the x-axis, as far as intercepitng the network pressure curve, according to the installed gas train (DN65, in the example). From the inter-

ception point, draw an horizontal line as far as matching, on the y-axis, the value of pressure necessary to get the requested furnace

input. This value must be lower or equal to the p

gas

value, calculated before.

Data requested:

z

furnace input;

z

air temperature

z

altitude

z

generator pressure or temperature

Example:

z

furnace input: 9600kW

z

air temperature: 15°C

z

altitude: 0m

z

generator pressure (only for steam generators): 12bar

Fig. 2

Fig. 3

TP1030

TP1050

TP91A

TP90A

TP92A

TP93A

TP512A

TP515A

TP520A

TP525A

0

2000

4000

6000

8000

10000

12000

14000

16000

Power output diagram at 15àC air temperature

Burner performance range

Tipo / Type P60

M-...50 (Multibloc DUNGS MB-DLE 420 B01)

M-...65 (Filtro / Filter DN65+ SIEMENS VGD40.065 +SKP1x+SKP2x)

0

5

10

15

20

25

100

200

300

400

500

600

700

800

900

Potenza / Output (kW)

M

ini

ma pr

essi

one gas i

n

re

te

/ Min

im

u

m

in

le

t g

as

pr

essur

e (

m

bar

)

Rp 2" (50)

DN65

Содержание TP512A

Страница 43: ...CIB UNIGAS M039177CA 43 Wiring diagram 21 001 2 Progressive burners ...

Страница 44: ...CIB UNIGAS M039177CA 44 Wiring diagram 21 001 2 Fully modulating burners ...

Страница 46: ...CIB UNIGAS M039177CA 46 ...

Страница 47: ...CIB UNIGAS M039177CA 47 ...

Страница 48: ...CIB UNIGAS M039177CA 48 ...

Страница 49: ...CIB UNIGAS M039177CA 49 WIRING DIAGRAM Cod 09 315 1 Burners type TP525A Mod M MD x xx x 1 xx ...

Страница 50: ...CIB UNIGAS M039177CA 50 ...

Страница 51: ...CIB UNIGAS M039177CA 51 ...

Страница 52: ...CIB UNIGAS M039177CA 52 ...

Страница 55: ...CIB UNIGAS M039177CA 55 ...

Страница 56: ......