SECTION 6

38

NOTES

1.

Make functional check of the flow switch in the following way before starting

the coater. Close the cooling water valve temporarily to check that the GUN

WATER indicator goes out. Then slowly open the valve to feed water and

check that the indicator lights when the flow rate exceeds the necessary

minimum value mentioned in the electron beam gun instruction manual. If the

flow switch does not operate properly, adjust the operating point.

The minimum flow rate is 10 L/min.

2.

The life of the insulator and filament largely depends on the operating

conditions of the electron beam gun. This section describes the frequency for

checking the insulator and filament so that the life expectancy under user

’

s

operating conditions can be known.

3.

The filament lead, made of copper, tends to be worn by ionized gas particles in

sputtering. A worn lead may be heated and broken if the electron beam gun is

operated at high power. Loose connection causes an unstable filament current

because of the contact resistance and will result in an unstable beam current.

In that event, the connection will be heated. The lead is subject to local

sputtering. Replace it when the thickness of the sputtered portion has become

80 of the initial size.

4.

If the lead of the X-axis or Y-axis for the deflecting coil is within 20 mm from

the filament lead, discharge will take place between the two wires and may

break down the magnet control circuit. Make sure the lead is not in a state

susceptible to short with ground or to breakage at the joint with the deflecting

coil feed-through or terminal. Use care especially after change of filament or

cleaning of the crucible area.

5.

The high voltage feedthrough is heated with heat from the electron beam gun.

This temperature cyclic makes screws easily loosened and periodical

retightening necessary.

6.

The emitter assembly gets very hot during operation. The temperature cycle

tends to loosen screws and the screws must be retightened periodically.

7.

Imperfect grounding can be very dangerous. Check the connections of the

ground cable and avoid use of an unnecessarily long ground cable. For

grounding requirements, see the E/B gun power supply instruction manual.

8.

It is recommended to use distilled water for cooling maintain cooling efficiency.

Generally, city water or well water can be used as it is, but its quality must be

less than 100 ppm (hard water of which salts contents in one liter are 100 mg as

converted to calcium carbonate). Water of poor quality tends to deposit fur on

Содержание EGL-206M

Страница 2: ...EB0007 03e...

Страница 3: ...EB0007 03e...

Страница 10: ......

Страница 13: ...SECTION 1 3 Fig 1 1 Dimensional Drawing for EGL 206M EGL 406M...

Страница 24: ...SECTION 3 14 Fig 3 1 Installation of two or more electron beam guns...

Страница 26: ...SECTION 3 16 Fig 3 3 Typical water cooling piping arrangement...

Страница 27: ...SECTION 3 17 Fig 3 4 Wiring arrangement in vacuum chamber...

Страница 28: ...SECTION 3 18 VIEW PORT LEADEN GLASS X RAY SUS304 SHIELD GASKET BELLJAR TARGET Fig 3 5 X ray shield...

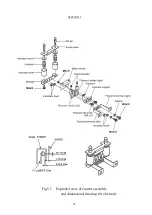

Страница 38: ...SECTION 5 28 Fig 5 1 Exploded view of emitter assembly and dimensional drawing for electrode...

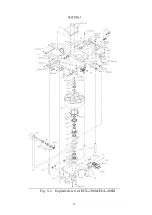

Страница 42: ...SECTION 5 32 Fig 5 2 Exploded view of EGL 206M EGL 406M...

Страница 43: ...SECTION 5 33 Fig 5 3 Exploded view of emitter assembly Fig 5 4 Exploded view of Limit switch assembly...