QUICK START GUIDE

u-line.com

QUICK START GUIDE

u-line.com

CAUTION

!

Too large of an adjustment to the screw can

cause the water to overflow the ice maker and

can cause property damage.

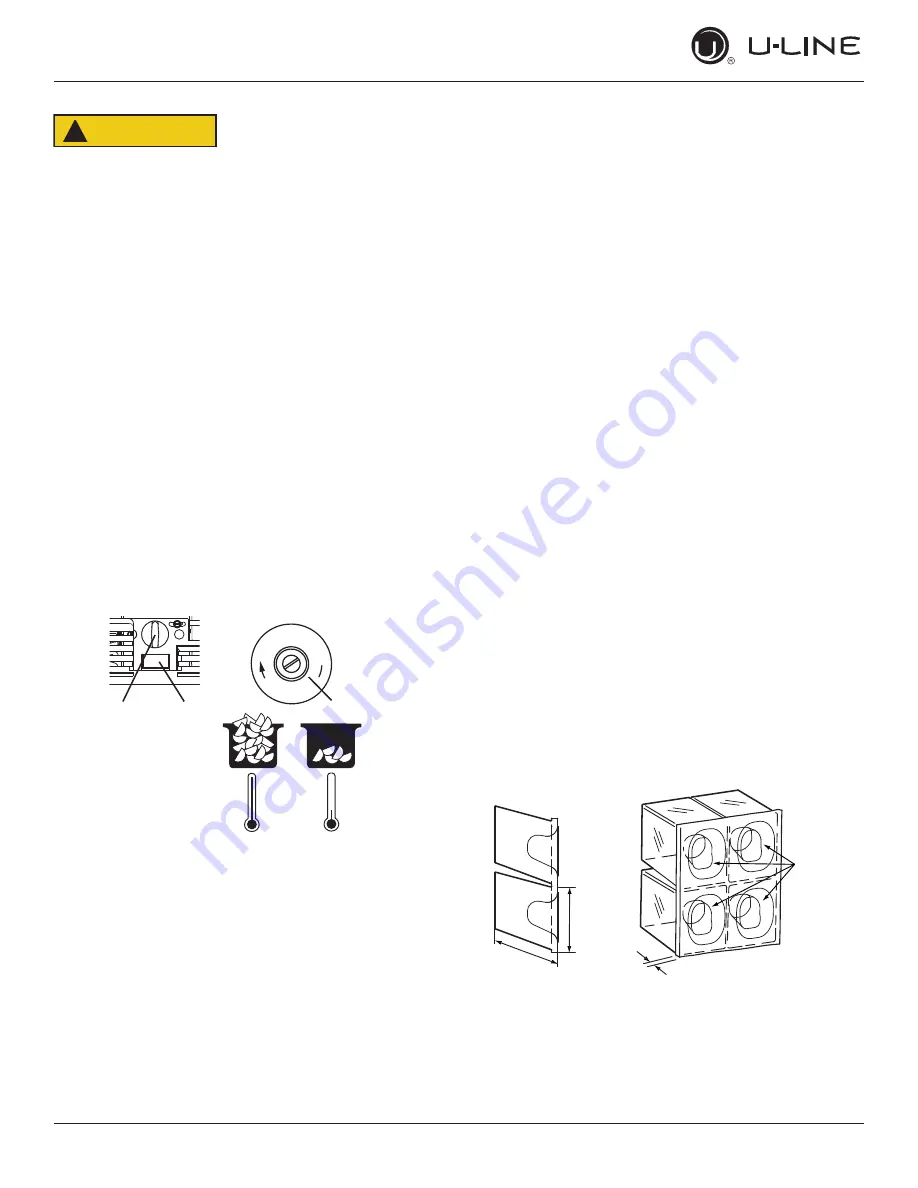

3. Turn the adjusting screw toward the minus (-) sign

(clockwise) for smaller cubes or toward the plus (+)

sign (counterclockwise) for larger cubes.

4. Install the ice maker assembly cover.

ADJUSTING ICE HARVEST

1. Remove the front grille

2. Using a flat tip screwdriver, turn the adjusting screw

(3) a small increment clockwise for a COLDER setting

(slower ice production) or counterclockwise for a

WARMER setting (faster ice production).

3. Reinstall the front grille (two screws).

CLEAR ICE MACHINES

ICE CUBE THICKNESS ADJUSTMENT

Ice thickness adjustment should only be made

one increment at a time. Allow ice maker

production to stabilize for 24 hours before

rechecking ice thickness.

Ice is produced in layers resulting in a clear cube. Ice in

bin may develop surface frost which disappears when cube

is placed in liquid.

Ice cubes in any given batch will vary, so it is necessary

to choose cubes from the sample area for comparison

when making adjustments.

The ice cube thickness is factory set for best overall

performance. The factory setting is designed to maintain

an ice bridge of approximately 1/16" to 1/8" (1.6 mm to

3.2 mm) under normal conditions, resulting in a dimple of

approximately 1/4" to 1/2" (6.4 mm to 12.7 mm) in

depth. A fuller cube with less of a dimple results in a

thicker ice bridge. As the ice bridge becomes thicker, the

tendency for the cubes to stay together as a slab

increases. A bridge thicker than 1/8" (3.2 mm) may cause

cubes to overfill the ice bucket.

32 ice cubes are formed on a 4 x 8 slab during each cycle.

Each cycle takes approximately 15-20 minutes at the

default cube thickness (0).

CO

LDER

Warmer Colder

3

1

2

DIMPLES

ICE BRIDGE

7/8"

(22 mm)

7/8"

(22 mm)

24

27