TYROLIT

Hydrostress AG

Page 21

Ring saw HRH500

Faults

8

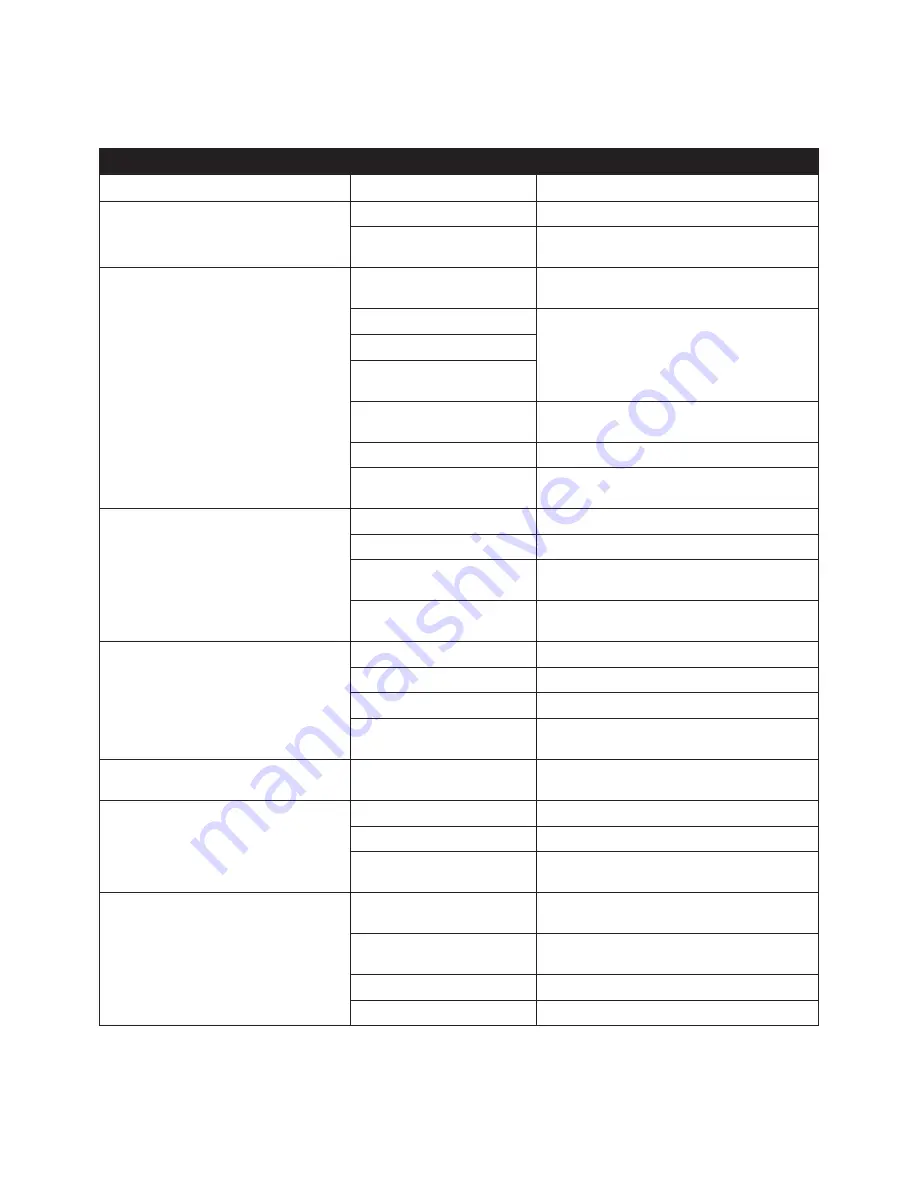

Faults

Fault

Possible cause

Solution

Ring saw does not start

Drive unit switched off

X

Switch on drive unit.

Emergency STOP on drive unit

pressed

X

Re-set emergency STOP.

Cutting ring does not rotate

Cutting ring not located cor-

rectly on the profiled drive roller

X

Mount the cutting ring correctly.

Incorrect hose connection

X

Check hydraulic system.

Hydraulic motor fault

Oil delivery not connected

properly

Main drive unit motor not

switched on

X

Switch on main motor.

Drive rollers dirty

X

Clean drive rollers.

Roller pre-tension device not

engaged

X

Check roller pre-tension device.

Cutting ring revolves too slowly

Drive rollers worn

X

Change drive rollers.

Roller bearing defective

X

Change roller bearing.

Inadequate oil flow and pres-

sure

X

Check drive unit.

Roller pre-tension device not

engaged

X

Check roller pre-tension device.

Cutting ring disengages

Roller distance too large

X

Check roller pre-tension device.

Drive rollers worn

X

Change drive rollers.

Cutting ring damaged

X

Change cutting ring.

Roller pre-tension device not

engaged

X

Check roller pre-tension device.

Cutting ring twisted

Cutting ring inadequately

cooled

X

Check water cooling.

X

Change cutting ring.

Diamond segments broken off

Cutting ring twisted

X

Change cutting ring.

Hard resistance in work piece

X

Change cutting ring.

Brazing or welding of segments

not professional standard

X

Change cutting ring.

Motor seal split

Ring saw runs backwards

X

Check hydraulic connections and drive unit oil

circuit.

Pressure too high

X

Check setting at drive unit. If necessary, install

a pressure reducing valve and a flow divider.

Defective seal

X

Replace seal.

Oil return incorrectly connected

X

Check connector.