unit as shown in Figure 1. Follow proper grounding procedures as required by IEEE and/or

the applicable standards in your area. Use of a ground mat and a running ground on the

conductor are highly recommended.

4.

Put a hazard barrier around the perimeter of the unit to keep unauthorized personnel away

from the equipment.

5.

Perform daily preventive maintenance.

THREADING THE BULLWHEELS

While looking at the bullwheels from the rear of the unit, the cable can be wrapped around the

bullwheels or installed according to the following procedure:

1.

Release the bullwheel brakes by turning the bullwheel pressure control counter-clockwise.

2.

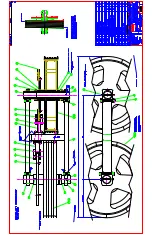

Thread the bullwheels with a length of rope by starting with lower bullwheel and wrapping it

around the top bullwheel while moving from right to left. See Figure 2.

3.

Connect the rope to the pulling line.

4.

Pull the rope to rotate the bullwheels until the pulling line is threaded around the bullwheels.

5.

Connect the pulling line to the conductor.

6.

Apply the brakes by turning the bullwheel pressure control clockwise.

Figure 2: Reeving the Bullwheels

TENSIONING

The function of the tensioner is to control the release of the conductor from the storage reel so

that the required sag between the towers will be maintained. Tension the conductor according to

the following procedure:

1.

Perform the field set up.

2.

Thread the bullwheels.

3.

Adjust the reelshaft brake to provide tail tension from the reel to the bullwheels

4.

Turn the bullwheel tension control fully clockwise to hold the tensioner bullwheels stationary.

5.

When the pulling machine starts, turn the tension control counter-clockwise slowly until the

bullwheels start to turn.

6.

Re-adjust the reelshaft brake control to adjust the tail tension from the reel to the bullwheels.

Содержание T50 BWRC

Страница 11: ......

Страница 12: ......

Страница 24: ......

Страница 25: ......

Страница 26: ......

Страница 27: ......

Страница 28: ......

Страница 29: ......

Страница 30: ......

Страница 31: ......

Страница 32: ......

Страница 33: ......

Страница 34: ......

Страница 35: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 43: ...www dexteraxle com OPERATION MAINTENANCE SERVICE MANUAL 600 8 000 lb Axles Related Components ...

Страница 125: ...Service Record Date Service Performed Mileage ...

Страница 126: ...Service Record Date Service Performed Mileage ...

Страница 127: ...Service Record Date Service Performed Mileage ...