5

EN

Operating manual – rotary hammer PRDS 10-230V

Caution

Vibration emissions can cause a health hazard if the

device is used for an extended period of time or if it is

not properly handled and maintained.

Caution

Keep a sufficient distance from heat sources.

Note

If you store or transport the device improperly, the

device may be damaged.

Note the information regarding transport and storage of

the device.

Behaviour in the event of an emergency

1. Switch the device off.

2. In an emergency, disconnect the device from the mains

feed-in: Hold onto the mains plug while pulling the power

cable out of the mains socket.

3. Do not reconnect a defective device to the mains.

Information about the device

Device description

The rotary hammer

PRDS 10-230V

comes equipped with a

pneumatic hammer mechanism for high impact power and is

ideally suited for continuous high-performance operations.

The infinitely variable impact rate and speed control allows you

to optimally adjust the exertion of force to every application and

material. A function selector switch with safety lock permits the

safe switch-over between functions.

The SDS-plus system tool holder makes it possible to exchange

the insertion tools easily and without the need for further tools.

Standard drilling accessories can also be used with an

optionally installable key-type drill chuck.

The additional handle ensures more stability and safety during

the drilling / chiselling operation.

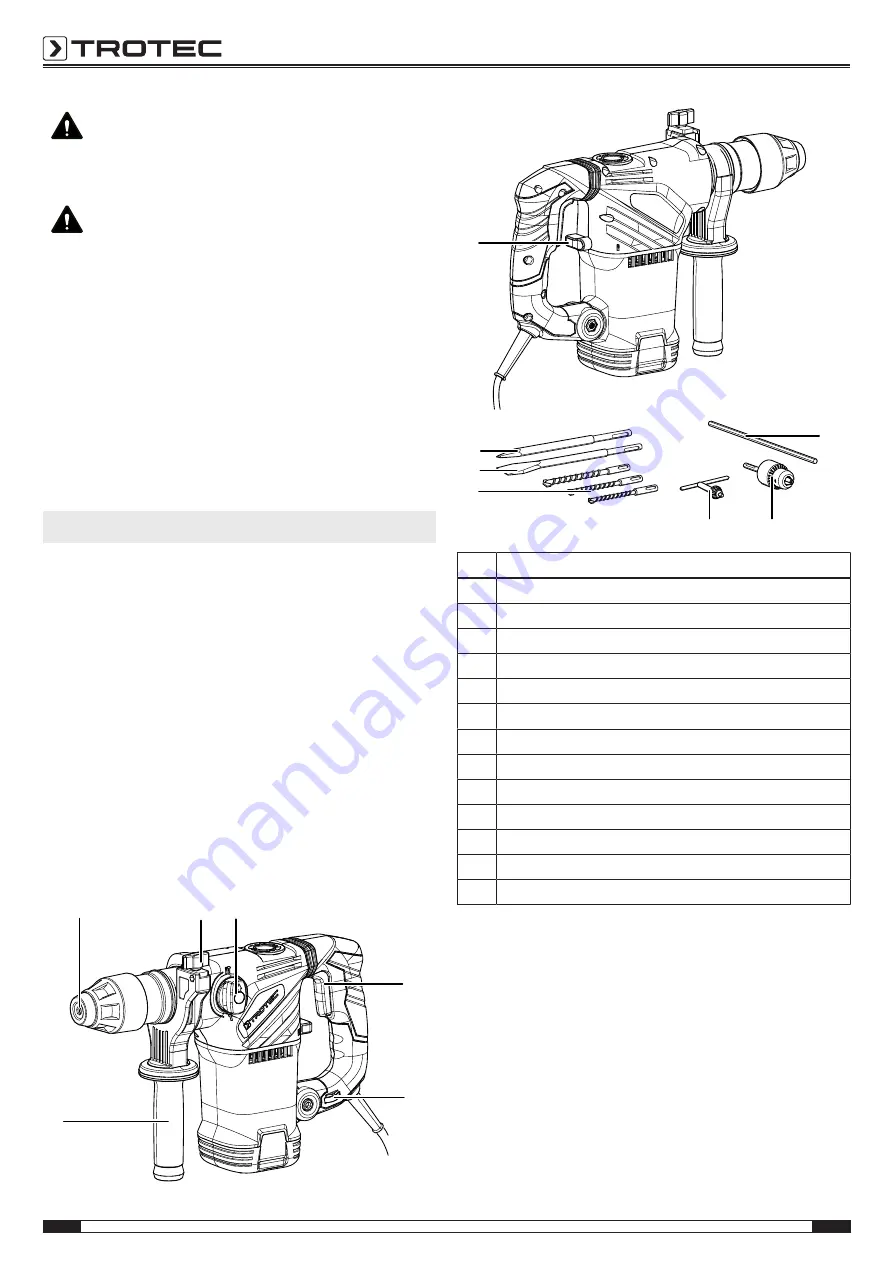

Device depiction

1

2

3

5

13

4

6

7

8

9

10

12

11

No.

Designation

1

SDS-plus system tool holder

2

Fastening screw depth stop

3

Function selector switch with release button

4

Power button

5

Setting wheel speed selection

6

Depth stop

7

Key-type drill chuck with SDS shank

8

Drill chuck key

9

SDS drill bit

10

SDS flat chisel

11

SDS pointed chisel

12

Switch for the impact mechanism

13

Additional handle

Scope of delivery

•

1 x Device

PRDS 10-230V

•

1 x Depth stop

•

1 x Key-type drill chuck with SDS shank

•

1 x Drill chuck key

•

3 x SDS drill bits (8/10/12 x 250 mm)

•

1 x SDS flat chisel (14 x 250 mm)

•

1 x SDS pointed chisel (14 x 250 mm)

•

1 x Additional handle

•

1 x Transport case

•

1 x Manual

Содержание PRDS 10-230V

Страница 1: ...TRT BA PRDS10 230V TC 002 EN PRDS 10 230V EN ORIGINAL INSTRUCTIONS ROTARY HAMMER ...

Страница 16: ......