EN

15

condenser dryer DH 160 / TTK 1600

Activities required before starting maintenance

Wear safety glasses

For start-up, maintenance and troubleshooting always

wear suitable safety glasses.

Wear a protective mask

For cleaning and maintenance tasks wear an

appropriate protective mask.

Wear protective gloves

For start-up, maintenance and troubleshooting always

wear suitable protective gloves.

Wear foot protection

For transportation, start-up, maintenance and

troubleshooting always wear suitable foot protection.

Warning of electrical voltage

Do not touch the mains plug with wet or damp hands.

•

Switch the device off.

•

Hold onto the mains plug while pulling the power cable out

of the mains socket.

Warning of electrical voltage

Tasks which require the housing to be opened

must only be carried out by authorised specialist

companies or by Trotec.

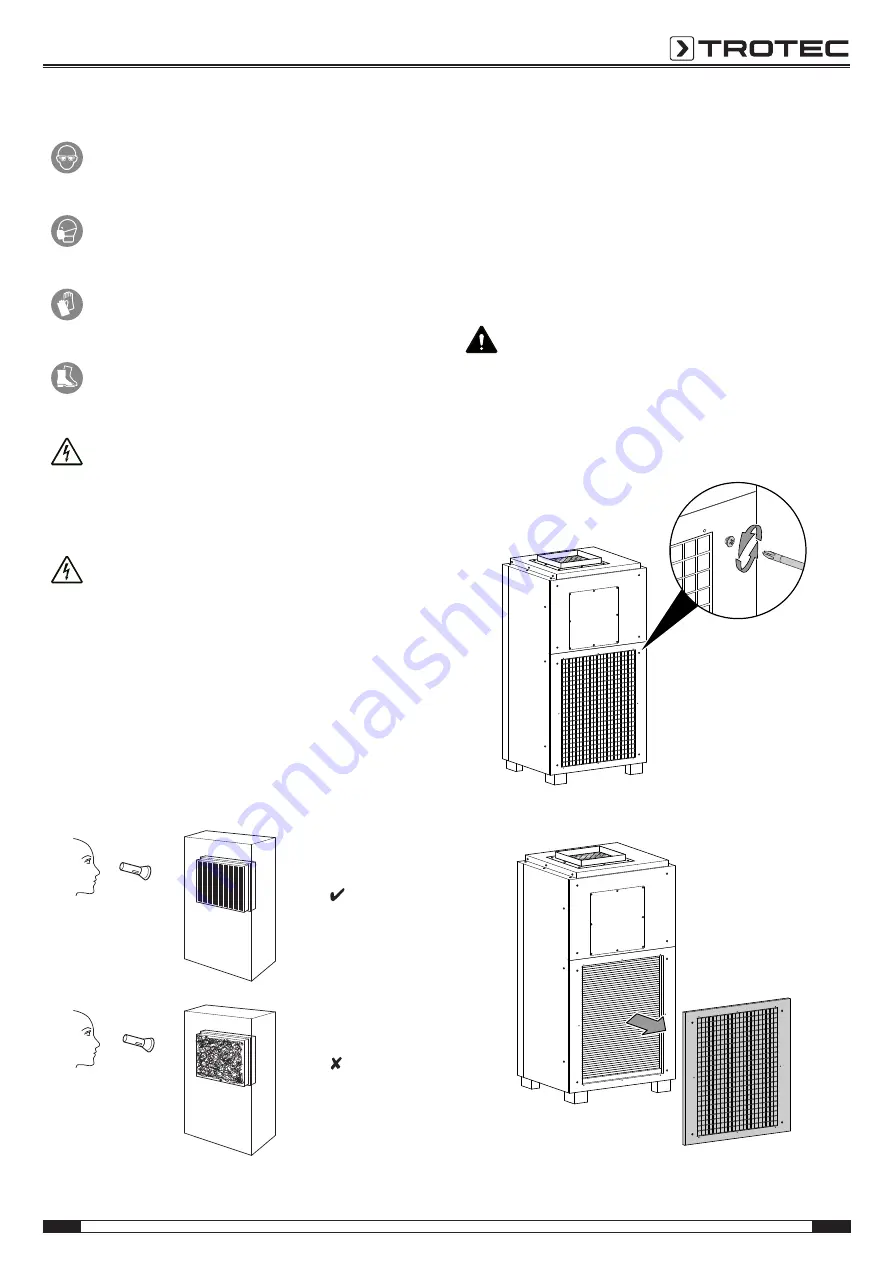

Visual inspection of the inside of the device for dirt

1. Remove the air filter.

2. Use a torch to illuminate the openings of the device.

3. Check the inside of the device for dirt.

4. If you see a thick layer of dust, have the inside of the

device cleaned by a specialist company for cooling and air-

conditioning or by Trotec.

5. Put the air filter back in.

Refrigerant circuit

•

The entire refrigerant circuit is a maintenance-free,

hermetically sealed system and may only be maintained or

repaired by specialist companies for cooling and air-

conditioning or by Trotec.

Cleaning the air filter

The air filter has to be cleaned as soon as it is dirty. This is

brought to light e.g. by a reduced capacity (see chapter Errors

and faults).

Warning

Ensure that the air filter is not worn or damaged. The

corners and edges of the air filter must not be

deformed or rounded. Before reinserting the air filter,

make sure that it is undamaged and dry!

1. Loosen the four attachment screws at the air inlet cover (4)

with 1/4 turn.

2. Remove the air inlet cover with filter (4) from the device.