Aquasensation AS2000X

8

25 mm below the cold feed connection to the

hot water cylinder on the opposite side of the

cistern to the float operated valve

(see fig.2)

.

This minimises air ingress into the pipework.

Plumbing options other than those outlined

in these fitting instructions could impair the

performance. For example, if hot and cold

connections are made after draw-off points

to other outlets, (eg. washing machine, taps,

etc.) it could result in unstable flows and

temperatures should other appliances operate at

the same time.

Run the hot and cold pipework to the shower

position, making sure that the pipework does

not rise above the level of water in the cold

cistern at any point to avoid air locks. Under

normal site conditions 15 mm pipework will be

adequate.

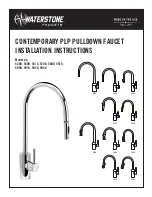

Decide the position of the shower. Cut the

pipework to the dimensions relevant to the

chosen direction of water entry into the shower.

IMPORTANT:

For rear entry only, the supplied

elbows must be used. For ease of installation,

the backplate area adjacent to the top pipe

inlet must be cut out, including the top left

wall fixing hole.

When fitting the elbows to incoming pipework,

ensure the elbow collets are fully engaged with

the pipe.

Dimensions are shown in

fig.9

and

fig.10

.

Note:

The pipe inlets are marked for hot and

cold connections – left-hand side for hot inlet on

bottom entry

(fig.11)

, but right-hand side for

hot inlet on top or rear entry

(fig.12)

.

IMPORTANT:

The fittings on the inlet elbows

are the push-in type. The pipework must be

cut with a pipe cutter and all burrs and rough

edges removed from the end of the tube. The

fittings can be used with copper and plastic

pipe.

If using chrome plated copper pipe, remove

the first 25 mm of plating completely from

the connecting surfaces. If not completely

removed then the collet will not grip the pipe

and under pressure the pipe may be forced

out.

Fig.9

Top

19 mm

26 mm

Cold

Hot

Area of

backplate

to remove

Wall

19 mm

34 mm

26 mm

Rear edge

of

backplate

Hot Cold

Wa

ll

Rear

23.5 mm

Bottom

Fig.10

Содержание AS2000X

Страница 25: ...Aquasensation AS2000X 23 Entry Points Diagram Key Water Entry Points Cable Entry Points...

Страница 26: ...Aquasensation AS2000X 24...

Страница 27: ...Aquasensation AS2000X 25...