Herrmidicool

I n s t a l l a t i o n , O p e r a t i o n & M a i n t e n a n c e M a n u a l

4

www.trioniaq.com

I. INTRODUCTION

The Herrmidicool system is an in-duct air/water atomization

system designed to introduce atomized water into the

airstream. The unit uses a native BACnet controller that

responds to an analog 0-5 VDC demand signal to start the

humidification process. An input for proving airflow prior to

starting the system is provided as well as alarm indication.

The touchscreen display allows the operator to interact with

the system. Network communications are available to allow

system monitoring and control.

II. OPERATIONAL CHARACTERISTICS

Upon an increase in demand signal above 20%, the controls

will energize the compressed air solenoid valve. An air

pressure switch will close if sufficient air pressure is present

to allow for proper atomization. When the air pressure switch

contacts close, the water solenoid valve will energize and

atomization will begin. Each nozzle is equipped with a clean

out pin that helps keep the water orifice clear of mineral build-

up each time the nozzle is cycled. Periodically, the controls

will de-energize the water solenoid valve in order to actuate

the clean-out pin to keep the water orifice clear. During

operation if the air proving switch contacts open, the system

will stop. If the system on/off switch is opened the system

will stop. See the Controls section for additional details.

Allowable Operating Conditions

Ambient Temperature: 40°-120°F (4°-50°C)

Ambient Relative Humidity: 0% - 90%

Line Voltage: -15% to +10% Nominal

Frequency: 50/60 Hz

Supply Air Pressure: 60-200 psig

Supply Air Quality: Filter clean and dry to 35°F dewpoint.

Supply Water Temperature: 40°-100°F (4°-38°C)

Supply Water Pressure: 50-100 psig

Supply Water TDS less than 50 ppm: Consult Factory

with water analysis and application data prior to selecting

equipment.

NOTE: If units are mounted in outdoor enclosures, conditions

inside enclosure must be maintained as listed above.

III. MOUNTING

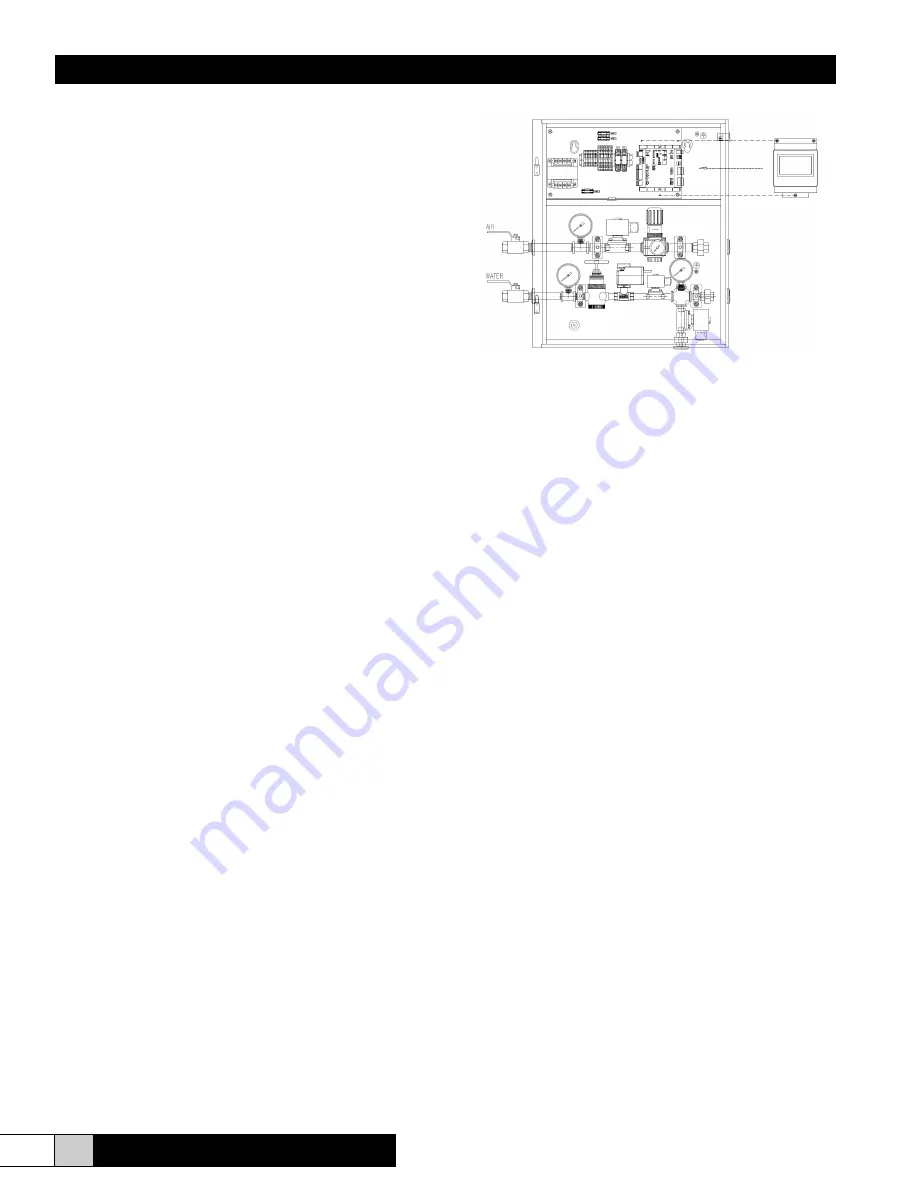

The Herrmidicool system consists of two basic components:

the control cabinet and the atomizing-head manifold

assembly. The control cabinet should be mounted so that the

water outlet of the control cabinet is level or below the water

manifold in the air handler. Air vents must be mounted on

any loops necessary to connect the cabinet to the manifolds.

Minimum Cabinet Clearances:

Top: 1” Bottom: 12”

Sides: 2” Front: 4”

32” Working Area Clearance

Hang the cabinet on the wall or unistrut mounting frame.

Two keyhole slots and two additional mounting holes are

provided. Be sure the unit is level and mounted directly

to the wall to wood studs as least 2” thick (or equivalent).

The atomizing head manifolds consisting of air manifolds,

atomizing heads, water manifold and unistrut brackets are to

be located as shown on specific layout drawings with each

job. Typically, a “unistrut” style mounting structure is field

fabricated to support the atomizing manifold.

Manifold Installation:

1. Install the air/water manifolds per the layout drawing

included with this package.

2. Use only copper, plastic or stainless steel piping as

specified in your print package.

3. Keep runs between control cabinets and heads as short

as possible.

4. Piping runs between control cabinets and manifolds

should be as direct as possible. If loops are unavoidable,

automatic air vents must be supplied and installed.

IV. PLUMBING

Each cabinet has an air inlet, water inlet, air outlet(s), water

outlet(s) and a drain. All air connections are ½” and all water

connections, including drain, are ½”.

1. Drain loop must extend 3” above highest location of

heads or water outlet port on cabinet. This loop allows water

pressure to be relieved on system shutdown.

2. Piping from control cabinet to manifolds without draining

should be ¾” for the air and ½” for the water piping unless

otherwise shown on your job specific drawings provided for

your project.