Herrmidicool

I n s t a l l a t i o n , O p e r a t i o n & M a i n t e n a n c e M a n u a l

6

www.trioniaq.com

(0-5 VDC). When the demand is greater than 20% (1 VDC),

the system will enable the compressed air solenoid valve;

starting the system. On any screen, the user may return

to the HOME screen by touching the house pictured in the

upper left of the screen.

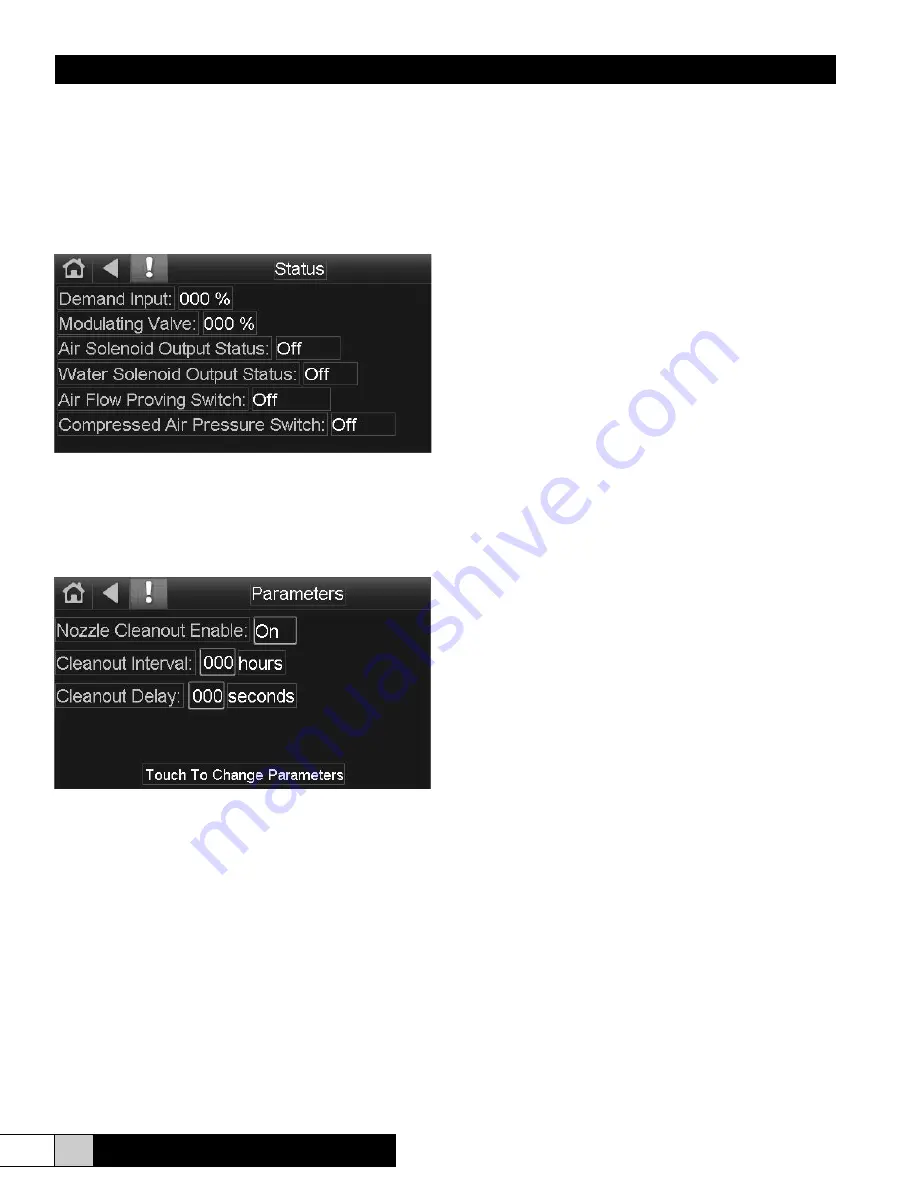

The STATUS, PARAMETERS, & ALARM, screens are

described below.

The STATUS screen (shown above) displays the state of

the inputs and outputs. The demand Input displays the

percentage of demand being supplied to the controller input.

This screen will show the user the status of the inputs and

ouputs.

The PARAMETERS screen (shown above) allows the user

to change the way the system works regarding nozzle

cleanout. If enabled, at the interval set by the parameter,

the water solenoid will de-energize for the duration set by

the Cleanout Duration parameter. If Nozzle Cleanout is

disabled, the system will operate continuously whenever

there is a demand input.

The ALARM screen (not shown) allows the user to check the

status of active alarms and alarm history. Whenever the red

exclamation point is shown on the screen, there is an active

alarm. If the exclamation point is gray, there are no active

alarms. The user may go to the alarm screen at any time

to check the history of alarms that have returned to normal

conditions.

There are two possible alarm conditions that may present

themselves during operation. They are the Air Proving Switch

and the Compressed Air Pressure Switch. After a demand

is present and the unit attempts to start, if either of these two

switch inputs fails to close, the unit will shut down and an

alarm will be present. Once the condition is corrected, the

unit will commence normal operation automatically.

The SETUP and MODULE STATUS screens are gateways to

lower level settings that should only be adjusted by a system

administrator. CHANGING SOME OF THESE SETTINGS

MAY RENDER THE FACTORY WARRANTY VOID

When touching SETUP or MODULE STATUS, the

administrator will be prompted for a password. Enter 2222 to

log in to the controller. Network settings, date and time may

be adjusted via the SETUP screen. The MODULE STATUS

screen should not be used without the direction of the factory.

The CLOCKSET screen allows the date, time, and daylight

savings time details to be programmed into the controller.

Unless the date & time are set, the controller will report

incorrectly on the ALARM screen.

VII. START-UP CHECKLIST

This Check List is intended to highlight critical installation

points. A poor installation frequently results in start-up

difficulties, and always results in less than ideal operation of

the humidifier.

1. Insure all valves and valve cocks through the system

(especially at every head) are shut-off.

2. Electric power is connected to the control cabinet per the

diagram.

3. All sensors, airflow switches and external inputs are

connected to the cabinet.

4. Air compressor is primed, oiled and air supply is

connected to the cabinet.

5. Air supply line has been purged and blown down to

remove any installation dirt.

6. Air supply line has been charged, leak tested and has a

minimum of 60 psi pressure to the cabinet.

7. Water supply is connected to the cabinet and has been

purged and blown down to remove installation dirt.

8. Water supply is charged and leak tested and has a

minimum of 50 psi pressure at the cabinet.

9. Drain loop has been connected to the bottom of the

cabinet and has been plumbed to an open drain.

10. Drain piping is installed with a loop a minimum of 3”

above atomizing heads and all piping after the cabinet.

11. All water piping from the cabinet to the manifolds is level

and without loops or automatic float type air vents have

been installed at high points to remove trapped air.

12. Air handler is completely operational and has been

balanced.

13. All air and water lines at the ends of the manifolds have

been terminated with hose bibs.

14. Mist eliminators, if used, have been installed properly

over drain pan that is trapped.