Dual Pneumatic

I n s t a l l a t i o n , O p e r a t i o n & S e r v i c e M a n u a l

11

www.trioniaq.com

Adjust air pressure regulator of control section to 30 psi.

Slowly move the CONTROL humidistat to a higher RH

until you hear a “click” indicating the 2-way solenoid valve

on the air control section has opened. NOTE: If only one

humidistat is used, follow above procedure slowly raising

RH setting, or if switch is used, turn to ON. Reduce the

setting on the SAFETY humidistat until you hear a click

indicating the 3-way solenoid on the water line has closed.

(If no safety humidistat is used, skip this step.) Open the

AIR valve ONLY on one pair of heads. There should be a

constant flow of air from the heads with no flow of water.

This will indicate that the controls for the control section

are properly wired. Make any corrections needed. Close

the air valve after determining wiring is correct. Repeat

the above at each control section in the system.

5. CLEAN DISTRIBUTION LINES FROM CONTROL

SECTIONS TO HEAD ASSEMBLIES.

IMPORTANT:

Be sure all air and water valves at head assemblies are

closed (Step 2). AIR LINES: Put on safety glasses. With

CONTROL humidistat ON and air valve at control section

open, place bucket and cloth over hose bib at end of each

air line and slowly open the hose bib and allow line to

blow clean. DO NOT LOOK INTO BUCKET WHILE AIR

IS BLOWING. Close hose bib. Repeat on all air lines

from each control section. WATER LINES: (Air valve at

control section should be open.) Set SAFETY humidistat

at maximum and CONTROL humidistat ON. Open water

valve at control section. Place bucket or hose on ends

of water lines and slowly open hose bibs. Allow water to

flow until clean. Throttle valve to avoid splashing. Close

hose bib. Close air and water valves at control section.

Repeat on all water lines from each control section.

6. STARTING THE SYSTEM.

Close air and water valves

at all control sections. Open air valves only at all head

assemblies. Set humidistats high enough to assure

system operation. Open AIR valve at control section.

With air flowing through heads, adjust primary air

pressure regulator (or compressor) to maintain 55 psi.

Adjust control section air pressure regulator to 30 psi.

With water valve open at water source, open the control

section water valve and the water valve of the ONE

head assembly located the GREATEST distance from

the control section. Adjust the primary water pressure

reducer to provide 45-50 psi to the control section.

Adjust control section water valve to provide 32-38 psi

to heads. Open the water valve at each head assembly,

checking and correcting for air and water leaks as you

go. CAUTION: Never let water pressure get below

air pressure as air will then get into water lines and

necessitate bleeding of lines. Repeat procedure on all

control sections and primary reducers. Normally, with all

heads operating, it will be necessary to again adjust the

primary water pressure reducer to 45-50 psi and control

section water pressure regulator to 32-38 psi. Tighten

the locknut on all WATER pressure regulators - primary

and control section. All further adjustments will be made

on air controls and at heads. With the entire system in

full operation, check for leaks in all air and water lines,

fittings, connections, valves, control sections, and head

assemblies. Correct as required.

7. FINAL ADJUSTMENTS TO HEADS.

Remove cap

(253206-00X) of each head. This cap is at the non-

discharge end of the head and covers the head adjusting

“spring tension nut” (253207-00X). Slowly turn this

adjusting nut in a clockwise direction until no water is

discharged by the head. Use care to avoid damage to

the valve seat. Then, back off this adjusting nut TWO full

turns counter clockwise. This may result in an excessively

heavy spray, but this will be adjusted later in the control

section. Replace cap. Repeat this operation on every

head on the system. NOTE: Maintain air pressure at 30

psi and water pressure at 32 - 38 psi. Do NOT let air

pressure exceed water pressure.

8. BALANCING THE SYSTEM.

The final and most

important adjustment will be made at the air pressure

regulator of each control section. Adjust the air regulator

to 30 psi; adjust water pressure for proper head capacity.

Increasing the air pressure to the heads results in smaller

droplet size in discharge pattern - and vice versa. Spray

pattern should be visible to at least 10’ from the head to

assure rated capacity. With the system in full operation,

adjust the safety humidistat to 10% above the desired

level. Remove the cover of this humidistat and set the

low and high limit stops to the RH setting so the setting

cannot be changed. Replace cover. Move the CONTROL

humidistat setting alternately lower and higher to cycle

the system OFF and ON several times until all gauges

become repetitive in action and readings.

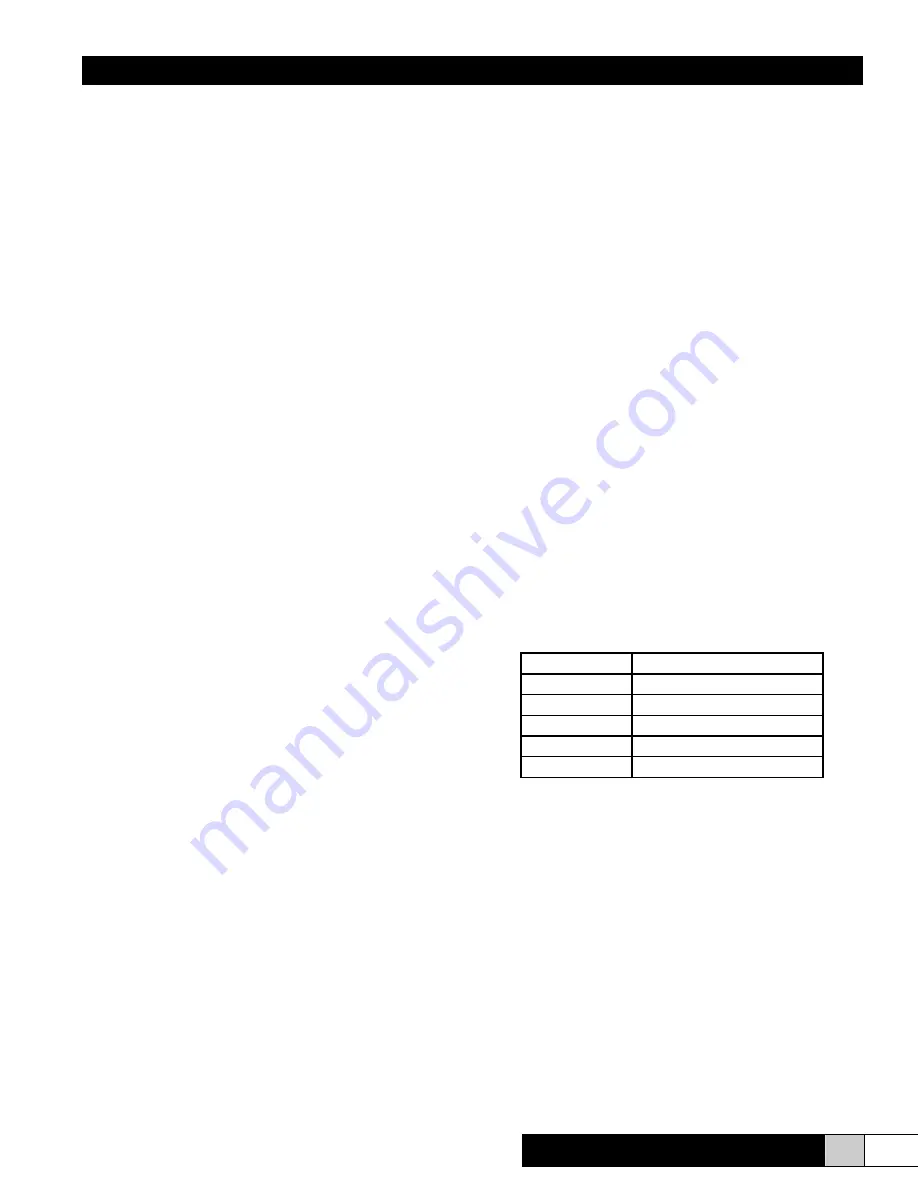

Water Pressure Settings

Head Capacity

Water Pressure Setting (PSI)

6

32

8

38

10

33

12

35

15

37

Note: A new system may require some adjustment until all parts are

properly seated during break-in. This period may last about two weeks.

After that, adjustments may not be required but should be checked on a

regular schedule. Set the humidistat at the desired level.

CAUTION:

1. Do not balance the system by adjusting individual heads. Each

head has been adjusted to provide its design capacity.

2. Do not throttle any valves at control sections or head assemblies to

get final adjustment.

VI. OPERATING INSTRUCTIONS

The Dual Pneumatic Atomizing System utilizes air and water

under pressure to atomize the water into tiny droplets (2-

15 microns with an average of 7.5). These droplets rapidly

evaporate to a gaseous state to raise the level of relative

humidity.