37

Model 208B BEVELMASTER

®

92-1482 Rev. 190410

10.2

AIR MOTOR LUBRICATION

No maintenance is usually required on the air motor.

However, the air supply must flow through a filter/regulator/lubricator (FRL) unit

or separate units before arriving at the air motor.

The FRL unit must be maintained as required (frequency dependent on the basic

air supply) to keep the water trap drained, filter cleaned and the lubricator oil

reservoir filled so that a drop of oil every 2 to 5 seconds is flowing.

When the Model 208B BEVELMASTER™ is to be left idle for 24 hours or more

after being run on ‘wet’ air, squirt oil directly into the air motor inlet and run the

motor for two (2) to three (3) seconds. This prevents rusting and freezing of the

rotor.

10.3

LUBRICANT RECOMMENDATIONS

The drive gears require a high string lubrication grease such as ‘Chevron Ultra-

Duty Grease EP NCG12 (P/N 68-0024).

The air motor requires a Class 2 lubricant, viscosity of 100 to 200 SSU at 100° F

(38° C) minimum aniline point of 200° F (93° C).

• TRI TOOL INC. Air Tool Lubricant (P/N 68-0022)

• AMOCO – American Industrial Oil No. 32

• Atlantic Richfield – Duro Oil S-150

• Chevron – A.W. Machine Oil 32

• Exxon – Nuto H32

• Shell – Tellus Oil 32

The bearings in the air or electric motor which are sealed, do not require

lubrication.

Содержание BEVEL MASTER 208B

Страница 1: ...92 1482 Rev 190410 Model 208B BEVELMASTER ...

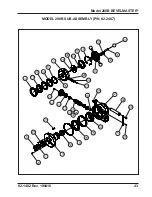

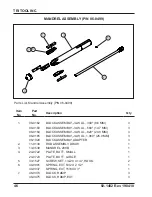

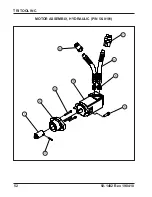

Страница 54: ...52 TRI TOOL INC 92 1482 Rev 190410 MOTOR ASSEMBLY HYDRAULIC P N 56 0101 5 3 1 2 4 10 9 6 8 7 ...

Страница 57: ...This Page is Intentionally Left Blank ...

Страница 58: ......