II. RECEIPT INSPECTION

All Traulsen products are factory tested for

performance and are free from defects when

shipped. The utmost care has been taken in

crating this product to protect against damage

in transit. All interior fittings have been

carefully secured to prevent damage.

You should carefully inspect your Traulsen

unit to assure that no damage has occurred in

transit. If, however, damage is detected, you

should save all the crating materials and make

note on the carrier’s Bill Of Lading describing

this. A freight claim should be filed immediate-

ly. If damage is subsequently noted during

or immediately after installation, contact the

respective carrier and file a freight claim.

Under no condition may a damaged unit be

returned to Traulsen & Co. without first obtain-

ing written permission (return authorization).

III. INSTALLATION

III. a - LOCATION:

Select a proper location for your Traulsen

unit is very important.

Always:

- Install to assure that unit is level.

- Install to assure that unit is away from

extreme heat.

- Install to assure that unit is away from

a steamer.

- Install to assure that unit is NOT placed near

or under a ventilation duct or hood, (this will

disturb the airflow of the air curtain and will

hamper the performance of the unit).

- Install to assure that unit is 6” minimum

distance from back of unit to wall or

obstruction (ie; a wall).

- Install to assure that the door(s) may

open a minimum of 90 degrees.

Never:

- Install equipment in an area of

standing water

- Install near or under a ventilation

hood or duct return

- Install equipment in an area not conductive

to safe and proper operator use.

III. b - PACKAGING:

Traulsen Air Curtain units are shipped from the

factory on a wooden pallet and packaged in a

durable cardboard container. The carton is

attached to the wooden skid with the use of

large staples. These should first be removed to

avoid scratching the unit when lifting off the

-2-

III. INSTALLATION (con’t)

crate. Remove the wooden pallet and strapping

material, and the unit should be rolled off the

skid. Avoid laying the unit on its front, side or

back for removal of the pallet.

NOTE: Traulsen does not recommend laying

the unit down on its front, side or back.

However, if you must please be certain to

allow the unit to remain in an upright position

afterwards for 48 hours before plugging the

unit in or attempting to place the unit in to

service, to assure that the compressor oils

and refrigerant may settle.

III. c - CLEARANCE:

It is important for the proper operation and

longevity of your Traulsen unit that it have

adequate provisions for air supply to the

compressor. Allow approximately 6” - 12”

between the back grill of the unit and the

wall for proper air flow.

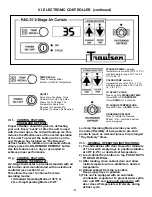

III. d - WIRING DIAGRAM:

Refer to the wiring diagram for any service

work performed on the unit. Should you

require one, please contact Traulsen Service

at (800) 825-8220, and provide the model

and serial number of the unit involved.

III. e - CORD & PLUG:

Traulsen Air Curtain models are supplied with

a cord & plug attached. It is shipped coiled at

the bottom of the cabinet, secured by a nylon

strip. For your safety and protection, all units

supplied with a cord and plug include a special

three-prong grounding plug on the service

cord. Select only a dedicated electrical outlet

with grounding plug for power source.

NOTE: Do not under any circumstances, cut

or remove the round grounding prong from

the plug, or use an extension cord.

III. f - POWER SUPPLY:

The supply voltage should be checked prior

to connection to be certain that proper voltage

for the cabinet wiring is available (refer to the

serial tag to determine correct unit voltage).

Make connections in accordance with local

electrical codes. Use qualified electricians.

Use of a separate, dedicated 20 amp circuit is

required. Size wiring to handle indicated load

and provide necessary overcurrent protector

in circuit (see amperage requirements on the

unit’s serial tag).

Содержание RAC37

Страница 11: ...10 X WIRING DIAGRAM V 15 0 2 Stage V 15 0...