VII. CARE & MAINTENANCE

WARNING: RISK OF ELECTRICAL

SHOCK. DISCONNECT ELECTRICAL

POWER SUPPLY BEFORE CLEANING

ANY PARTS OF THE UNIT OR PRIOR

TO ANY SERVICE.

VII. a - CLEANING THE CONDENSER:

The most important thing you can do to insure

a long, reliable service life for your Traulsen is

to regularly clean the condenser coil. The

condensing unit requires regularly scheduled

cleaning to keep the finned condenser clean

of lint and dust accumulation. Keeping the

condenser clean allows the cabinet to

operate more efficiently and use less energy.

To clean the condenser, first disconnect electri-

cal power to the cabinet and remove the front

and/or rear louver assembly. To remove this,

remove the screws located on louver assembly.

Once the screws are removed, the panel can be

removed allowing full access to the front facing

condenser. Vacuum any dirt, lint, or dust from

the finned condenser coil, the compressor and

other cooling system parts. If significant dirt is

clogging the condenser fins, use brush or

compressed air to blow this clear. Care should

be taken not to bend any of the condenser

fins, as this will reduce performance and

compressor life. Replace louver assembly

and screws which hold it in place.

VII. b - CLEANING THE EXTERIOR:

Exterior stainless steel should be cleaned

with warm water, mild soap and a soft cloth.

Apply with a dampened cloth and wipe in

the direction of the metal grain.

Avoid the use of strong detergents and gritty,

abrasive cleaners as they may tend to mar and

scratch the surface. Do NOT use cleansers

containing chlorine, this may promote

corrosion of the stainless steel.

Care should also be taken to avoid splashing

the unit with water containing chlorinated

cleansers, when mopping the floor around

the unit.

For stubborn odor spills, use baking soda and

water (mixed to a 1 TBSP baking soda to 1 pint

water ratio).

VII. c - CLEANING THE INTERIOR:

For cleaning stainless steel interiors, the use of

baking soda as described in section “VII. b” is

recommended. Use on breaker strips as well as

door gaskets. All interior fittings are removable

without tools to facilitate cleaning.

VIII. OTHER

VIII. a - SERVICE INFORMATION:

Before calling for service, please check the

following:

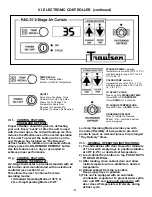

If the unit is NOT COOLING down to the proper

temperatures, verify that the coil is defrosted.

Push the “momentary defrost” button

on the control panel. Allowing proper

defrosting of the coil will allow proper

performance in capacity.

If the unit is NOT WORKING at all, please

check the following;

Is the electrical cord plugged in?

Is the circuit breaker on and fuse OK?

Is the “ON” indicator light illuminated?

Press POWER On/Off button to illuminate.

If after checking the above items and the unit

is still not operating properly, please contact an

authorized Traulsen service agent. A complete

list of authorized service agents was provided

along with your Traulsen unit. If you cannot

locate this, you may also obtain the name of

a service agent from the Tech Service page of

our website: www.traulsen.com.

If service is not satisfactory, please contact

our inhouse service department at:

Traulsen & Co., Inc.

4401 Blue Mound Road

Fort Worth, TX 76106

(800) 825-8220

Traulsen & Co., Inc. reserves the right to

change specifications or discontinue models

without notice.

VIII. b - SPARE PARTS:

Spare or replacement parts may be obtained

through a parts supplier or one of our

authorized service agents. A complete list of

authorized service agents accompanies this

manual and is also posted on our company’s

official website @ www.traulsen.com.

VIII. c - WARRANTY REGISTRATION:

For your convenience, the warranties on your

new Traulsen unit may be registered with us by

one of two methods. Completing the enclosed

warranty card (shipped with the unit), or by

filling out the on-line warranty registration form

located on the Technical Service page of our

website (www.traulsen.com).

-6-

Содержание RAC37

Страница 11: ...10 X WIRING DIAGRAM V 15 0 2 Stage V 15 0...