TRANE

R

19

Assembly & Installation

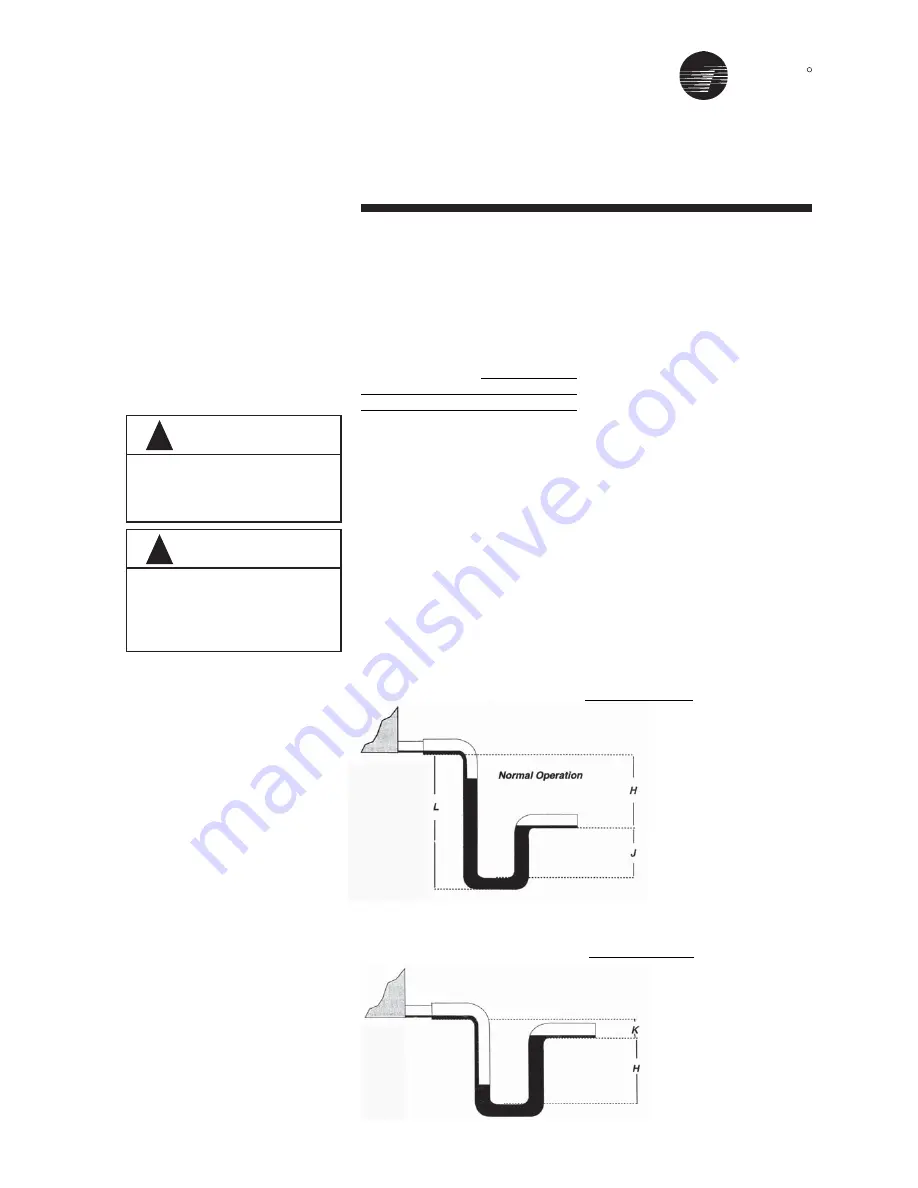

Piping - Condensate Drain

Pan Connections

On cooling section(s) the drain pan

should always be connected directly

to a trap to ensure proper drainage of

condensate.

Male-threaded, 1-1/2" BSPT conden-

sate drain connection is provided on

one side of the coil section. The main

drain lines and trap must be the same

size as the drain connection.

Pitch the connection line horizontal or

downward toward an open drain and

install a plugged tee to facilitate

cleaning. Condensate lines should not

be connected to a closed drain. This

is to avoid the possibility of drawing

sewer gasses into the unit.

Drain traps must be primed. lf they

are not, the trap is essentially non-

existent and the drain pan will likely

overflow.

CAUTION

!

Units With More Than One

Drain Pan

With the Trane Quantum

TM

Air Handler,

each module can be ordered with or

without a drain pan. When more than

one module has a drain pan, you must

trap each module individually.

Connecting all drains to a common line

with only one trap will result in

condensate retention, and possible

water damage to the air handler or

adjoining space.

If a module has a drain pan for cleaning

purposes only, it does not need a trap;

however a cap or shut off valve should

be installed on the drain connection.

Only modules handling condensate,

such as a cooling coil module or

eliminator module, require a trap.

Figure 9 through Figure 10 are

examples of typical installations.

IMPORTANT

!

Figure 9

Drain Pan Trapping for module under Negative Pressure

H = (1” for each 1” of

maximum negative

pressure) + 1”

J = 1/2 H

L = H + J + Pipe di

Insulation

Figure 10

Drain Pan Trapping for module under Positive Pressure

K = min. 1/2”

H = 1/2” plus maximum

total static pressure

Failure to provide adequate

condensate piping may result in

water damage to the equipment or

building.

The applicable "rule of thumb" for

amount of condensate may as high

as 6 lbs/hr/ton for units serving areas

with high latent heat.

Содержание TRANE Quantum CLCPEuro

Страница 2: ...TRANE R...

Страница 6: ...TRANE R 2 CLCPXP Model Nomenclature...

Страница 7: ...TRANE R CLCPEURO Model Nomenclature 3...

Страница 13: ...TRANE R Assembly Installation CLCPEuro CLCPXP External connection 9...

Страница 14: ...TRANE R Assembly Installation CLCPEuro Break Point 25mm Frame to Frame 10...

Страница 15: ...TRANE R 11 Assembly Installation CLCPEuro Break Point 25mm Panel to Frame...

Страница 16: ...TRANE R 12 Assembly Installation CLCPEuro Break Point 2 50mm Frame to Frame...

Страница 17: ...TRANE R Assembly Installation CLCPEuro Break Point 2 50mm Panel to Frame 13...

Страница 18: ...TRANE R Assembly Installation CLCPEuro Paneling 14...

Страница 19: ...TRANE R Assembly Installation CLCP XP Break Point 15...

Страница 20: ...TRANE R Assembly Installation CLCP XP Break Point 16...

Страница 21: ...TRANE R 17 Assembly Installation CLCP...

Страница 22: ...TRANE R Assembly Installation CLCP 18...

Страница 36: ...TRANE R Maintenance 32 Figure 18 Belt Tension Measurement...

Страница 39: ...TRANE R 35 Trouble Analysis Pulley and Belt...

Страница 45: ...TRANE R Appendix B HDT Unit Weight CLCPXP 41...

Страница 46: ...TRANE R Appendix B HDT Unit Weight CLCPXP 42...

Страница 47: ...TRANE R Appendix B HDT Unit Weight CLCPXP 43...

Страница 48: ...TRANE R Appendix B VDT Unit Weight CLCPXP 44...

Страница 52: ...TRANE R Appendix D Filter and Quantity 48 Filter Dimension and Arrangement High Capacity Filter CLCP Euro only...

Страница 53: ...TRANE R Appendix D Filter and Quantity 49 Filter Dimension and Arrangement Final Filter HEPA...

Страница 57: ...TRANE R Typical Wiring Diagram Starter Star Delta 380 420V 3Phase 4Wires ELCB Standard 53...

Страница 58: ...TRANE R 54 Typical Wiring Diagram Starter Dol 380 420V 3Phase 4Wires ELCB Standard...

Страница 59: ...TRANE R 55 Typical Wiring Diagram Starter Dol 380 420V 3Phase 4Wires Standard...

Страница 60: ...TRANE R 56 Typical Wiring Diagram VFD Starter Dol Bypass Starter C W Door Switch 380 415 440 460V 3Phase 3Wires...

Страница 61: ...TRANE R 57 Typical Wiring Diagram Starter Dol 380 420V 3Phase 4Wires ELCB Enhance with Thermistor Relay...

Страница 62: ...TRANE R 58 Typical Wiring Diagram Starter Dol 380 420V 3Phase 4Wires Standard...

Страница 63: ...TRANE R 59 Typical Wiring Diagram Starter Dol 380 420V 3Phase 4Wires Enhance with Thermistor Relay...

Страница 64: ...TRANE R 60 Typical Wiring Diagram Starter Star Delta 380 420V 3Phase 4Wires Enhance with Thermistor Relay...

Страница 65: ...TRANE R 61 Typical Wiring Diagram Starter Star Delta 380 420V 3Phase 4Wires Standard...

Страница 68: ...TRANE R 64...

Страница 70: ...TRANE R 66...

Страница 71: ...TRANE R...