TRANE

R

5.

6.

7.

8.

9.

10.

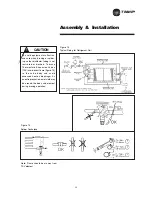

Assembly & Installation

Steam Coil Piping

Type A, AA Steam Coils

These are for central system, industrial

and process application with one row,

opposite-end connections. Maximum

standard operating limits:

Copper tubes: 100 psig and 400

o

F

Type AA coils feeds alternate tubes.

Refer to Figure 13 for typical steam coil

piping.

1. lnstall a 1/2 inch, 15 degree swing

check vacuum breaker in the

unused condensate return tapping

as close as possible to the coil.

2. Vent the vacuum breaker line to the

atmosphere or connect it to the

return main at the discharge side of

the steam trap.

Note: Vacuum breaker relief is

mandatory when the coil is controlled

by a modulating steam supply or a two-

position (ON-OFF) automatic steam

supply valve.

3. Run the return pipe at the full size of

the steam trap connection except for

the short nipple screwed directly

into the coil condensate connection.

Do not bush or reduce the coil return

tapping size.

4. Proper steam trap selection and

installation is necessary for

satisfactory coil performance and

service life. For installation, use the

following steps:

•

Select trap based on maximum

possible condensate rate.

•

Locate the steam trap discharge

at least 12 inches below the

condensate return tapping, this

provides sufficient hydrostatic

head pressure to overcome trap

losses and assure complete

condensate removal.

•

Float and thermostatic traps are

recommended because of gravity

drain and continuos discharge

operation.

•

Use float and thermostatic traps

are recommended because of

gravity drain and continuos

discharge operation.

•

Use float and thermostatic traps

with atmospheric pressure gravity

condensate return, with automatic

control or where the possibility of

low-pressure supply steam exists.

•

Use bucket traps ONLY when the

supply steams in unmodulated

and 25 psig or higher.

•

Always install strainers as close

as possible to the inlet side of the

trap. Do not modulate Type A, AA

coils. Use two position (ON-OFF)

steam supply controls.

Use a V-port modulating valve to

obtain gradual modulating action.

Do not modulate systems with

overhead or pressurized returns

unless the condensate is drained

by gravity to a receiver (vented to

the atmosphere) and returned to

the main by a condensate pump.

At start-up on units with fresh air

dampers, slowly turn the steam on

full at least 10 minutes before

opening the fresh air.

Pitch all supply and return steam

piping down minimum of 1-inch

per 10 feet in the direction of flow.

Do not drain the steam mains or

take-off through the coils. Drain the

mains ahead of the coils through

a steam trap to the return line.

Overhead return require 1 psig of

pressure at the steam trap

discharge for each 2 - feet

elevation to assure continuous

condensate removal.

AV - Automatic or manual air vent

GV - Gate valve

VB - Vacuum breaker

OV - Automatic two-position control valve

21

Figure 13

Typical Piping for Steam Coil

MV - Magnetic valve

FT - Float and thermostatic steam trap

ST - Strainer

CAUTION

!

Condensate must flow freely from

coil at all times to prevent physical

coil damage from water hammer,

unequal thermal stresses, freeze-up

and/or corrosion.

Complete the following recom-

mendations to prevent coil

damage.

CAUTION

!

Caution: Always open the steam

supply control valve slowly to

prevent possible coil damage.

Содержание TRANE Quantum CLCPEuro

Страница 2: ...TRANE R...

Страница 6: ...TRANE R 2 CLCPXP Model Nomenclature...

Страница 7: ...TRANE R CLCPEURO Model Nomenclature 3...

Страница 13: ...TRANE R Assembly Installation CLCPEuro CLCPXP External connection 9...

Страница 14: ...TRANE R Assembly Installation CLCPEuro Break Point 25mm Frame to Frame 10...

Страница 15: ...TRANE R 11 Assembly Installation CLCPEuro Break Point 25mm Panel to Frame...

Страница 16: ...TRANE R 12 Assembly Installation CLCPEuro Break Point 2 50mm Frame to Frame...

Страница 17: ...TRANE R Assembly Installation CLCPEuro Break Point 2 50mm Panel to Frame 13...

Страница 18: ...TRANE R Assembly Installation CLCPEuro Paneling 14...

Страница 19: ...TRANE R Assembly Installation CLCP XP Break Point 15...

Страница 20: ...TRANE R Assembly Installation CLCP XP Break Point 16...

Страница 21: ...TRANE R 17 Assembly Installation CLCP...

Страница 22: ...TRANE R Assembly Installation CLCP 18...

Страница 36: ...TRANE R Maintenance 32 Figure 18 Belt Tension Measurement...

Страница 39: ...TRANE R 35 Trouble Analysis Pulley and Belt...

Страница 45: ...TRANE R Appendix B HDT Unit Weight CLCPXP 41...

Страница 46: ...TRANE R Appendix B HDT Unit Weight CLCPXP 42...

Страница 47: ...TRANE R Appendix B HDT Unit Weight CLCPXP 43...

Страница 48: ...TRANE R Appendix B VDT Unit Weight CLCPXP 44...

Страница 52: ...TRANE R Appendix D Filter and Quantity 48 Filter Dimension and Arrangement High Capacity Filter CLCP Euro only...

Страница 53: ...TRANE R Appendix D Filter and Quantity 49 Filter Dimension and Arrangement Final Filter HEPA...

Страница 57: ...TRANE R Typical Wiring Diagram Starter Star Delta 380 420V 3Phase 4Wires ELCB Standard 53...

Страница 58: ...TRANE R 54 Typical Wiring Diagram Starter Dol 380 420V 3Phase 4Wires ELCB Standard...

Страница 59: ...TRANE R 55 Typical Wiring Diagram Starter Dol 380 420V 3Phase 4Wires Standard...

Страница 60: ...TRANE R 56 Typical Wiring Diagram VFD Starter Dol Bypass Starter C W Door Switch 380 415 440 460V 3Phase 3Wires...

Страница 61: ...TRANE R 57 Typical Wiring Diagram Starter Dol 380 420V 3Phase 4Wires ELCB Enhance with Thermistor Relay...

Страница 62: ...TRANE R 58 Typical Wiring Diagram Starter Dol 380 420V 3Phase 4Wires Standard...

Страница 63: ...TRANE R 59 Typical Wiring Diagram Starter Dol 380 420V 3Phase 4Wires Enhance with Thermistor Relay...

Страница 64: ...TRANE R 60 Typical Wiring Diagram Starter Star Delta 380 420V 3Phase 4Wires Enhance with Thermistor Relay...

Страница 65: ...TRANE R 61 Typical Wiring Diagram Starter Star Delta 380 420V 3Phase 4Wires Standard...

Страница 68: ...TRANE R 64...

Страница 70: ...TRANE R 66...

Страница 71: ...TRANE R...