Startup

56

OAU-SVX006E-EN

surrounding buildings or prevailing winds cause

recirculation, a flue extension may be required to

prevent recirculation. Contact manufacturer prior

to making any flue adjustments.

•

Reduced air delivery can also be the result of

inducer fan blade slippage, dirt accumulation in the

fan blade or low voltage to draft inducer motor.

Inspect draft fan assembly and be sure fan blade is

secure to motor shaft. Check line voltage to heater.

7. Flame Sensor Current Check

Flame current is the current which passes through the

flame from the sensor to ground. A flame signal of 0.5

to 1.0 microamp (

A) is marginal. For dependable

operation, a flame signal of greater than 1.0

A is

required. To measure flame current, connect a meter

capable of reading micro-amp current so the flame

signal will be read thru the meter’s COM and

A

connections. The meter should read greater than

1.0

A.

Note:

If the meter reads below “0” on scale, meter

leads are reversed; disconnect power and

reconnect meter leads for proper polarity.

NOTICE

Meter Damage!

Measuring voltage with meter connect to a circuit

could result in meter damage. Do NOT measure voltage

with meter connected to a circuit.

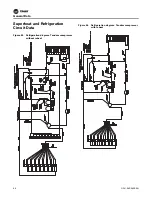

Figure 42.

Indirect fired gas furnace components

INDUCER MOTOR

IGNITION

CONTROLLERS

ON/OFF GAS VALVE

ON/OFF GAS VALVE

MANIFOLD GAS

PRESSURE TAP

AIR-PROVING

SWITCH

MINIMUM/MAXIMUM INLET PRESSURE =

7 IN. WC/14 IN. WC (1.7 KPA/3.5 KPA)

FOR NATURAL GAS AND 10 IN. WC/14 IN. WC

(2.5 KPA/3.5 KPA) FOR PROPANE

MANIFOLD GAS

PRESSURE TAP 3.5 in. wc

ROLLOUT SWITCH

MINIMUM/MAXIMUM INLET PRESSURE =

7 IN. WC/14 IN. WC (1.7 KPA/3.5 KPA)

FOR NATURAL GAS AND 10 IN. WC/14 IN. WC

(2.5 KPA/3.5 KPA) FOR PROPANE

CONDENSATE DRAIN

(TYP. 2)

INDUCER BLOWER

MODULATING VALVE

INLET PRESSURE TAP

5 in. wc

FLAME

SENSOR

HIGH LIMIT

SWITCH

ROLLOUT

SWITCH

MODULATING

GAS VALVE