OAU-SVX006E-EN

29

Installation

Ductwork

Elbows with turning vanes or splitters are recommended

to minimize air noise due to turbulence and to reduce

static pressure.

When attaching the ductwork to the unit, provide a water-

tight flexible connector at the unit to prevent operating

sounds from transmitting through the ductwork.

All outdoor ductwork between the unit and the structure

should be weather proofed after installation is completed.

Note:

For sound consideration, cut holes in the roof deck

only for the ductwork penetrations. Do not cut out

the roof deck within the entire curb perimeter. All

duct work must be installed and connected to top of

roof curb before the unit is set on curb.

If a Curb Accessory Kit is not used:

1. Be sure to use flexible duct connections at the unit.

2. Gaskets must be installed around the curb perimeter

flange and the supply and return air opening flanges.

Note:

For units will electric heat in the primary heating

position, refer to

.

Note:

A minimum 48" of straight duct is required before

an elbow. This is a requirement for both vertical

and horizontal discharge regardless of heat type.

For units with Indirect Fired Gas Heat:

•

Ductwork leaving unit should not have an immediate

duct tee.

•

If possible allow 4 feet vertical duct before first duct

tee.

•

Ensure duct work does not have an extreme transition

at the outlet of the unit. Extreme transitions can cause

restriction of airflow and high limit trips (as shown in

figure

•

Discharge Air sensor should be placed in the center of

the ductwork at least 4 feet from the unit or after the

first 90° bend.

WARNING

Hazardous Service Procedures!

Failure to follow all precautions in this manual and on

the tags, stickers, and labels could result in death or

serious injury.

Technicians, in order to protect themselves from

potential electrical, mechanical, and chemical hazards,

MUST follow precautions in this manual and on the

tags, stickers, and labels, as well as the following

instructions: Unless specified otherwise, disconnect all

electrical power including remote disconnect and

discharge all energy storing devices such as capacitors

before servicing. Follow proper lockout/tagout

procedures to ensure the power can not be

inadvertently energized. When necessary to work with

live electrical components, have a qualified licensed

electrician or other individual who has been trained in

handling live electrical components perform these

tasks.

AVERTISSEMENT

Procédures d’entretien dangereuses!

Le non-respect de toutes les précautions contenues

dans ce manuel ainsi que sur les étiquettes et les

autocollants peut entraîner des blessures graves voire

mortelles.

Les techniciens, afin d’être protégés des éventuels

risques électriques, mécaniques et chimiques,

DOIVENT suivre les précautions contenues dans ce

manuel, sur les étiquettes et les autocollants, ainsi que

les instructions suivantes : Sauf indication contraire,

coupez toute l’alimentation électrique y compris les

disjoncteurs à distance et déchargez tous les dispositifs

de stockage d’énergie comme les condensateurs avant

l’entretien. Respectez les procédures de verrouillage et

d’étiquetage appropriées pour éviter tout risque de

remise sous tension accidentelle. S’il est nécessaire de

travailler avec des composants électriques sous

tension, demandez à un électricien qualifié et agréé ou

à une autre personne ayant la formation nécessaire

pour manipuler des composants électriques sous

tension d’exécuter ces tâches.

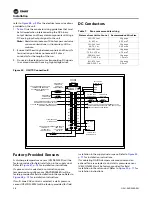

Figure 30.

Important:

Bottom discharge units with open coil

electric heater in primary heat location

require discharge duct with 90° elbow. This

is a MANDATORY installation requirement.

48 in. (121.9 cm)

minimum straight duct

distance before an elbow

for either gas heat

or electric heat

Airflow