18-CD20D1-18

7

Installer’s Guide

6

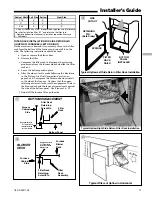

50 CU. FT. OR MORE

PER 1000 BTU/HR. INPUT

ALL EQUIP. INSTALLED

UNCONFINED

7

CONFINED

LESS THAN 50 CU. FT.

PER 1000 BTU/HR. INPUT

ALL EQUIP INSTALLED

8

Typical Suspended Upflow/Horizontal Furnace

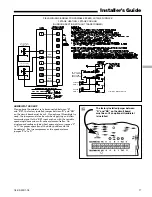

A cutout is provided on both sides of the downflow furnace

cabinet to allow a 90° elbow to be attached inside the cabinet

and the vent piping to connect there. In horizontal, the

downflow furnace may be vented through the top of the

cabinet if needed. In vertical configuration, the downflow

furnace may be vented using the side cabinet cutouts. This

venting configuration could be used if an electronic air

cleaner is installed.

When the downflow furnace is vented through the left

side of the furnace cabinet in horizontal or vertical

configuration, Type B vent pipe must be used within

the cabinet.

AIR FOR COMBUSTION AND VENTILATION

Adequate flow of combustion and ventilating air must not be

obstructed from reaching the furnace. Air openings provided

in the furnace casing must be kept free of obstructions which

restrict the flow of air. Airflow restrictions affect the effi-

ciency and safe operation of the furnace. Keep this in mind

should you choose to remodel or change the area which

contains your furnace. Furnaces must have a free flow of air

for proper performance.

Provisions for combustion and ventilation air shall be made

in accordance with “latest edition” of Section 5.3, Air for

Combustion and Ventilation, of the National Fuel Gas Code,

ANSI Z223.1, or Sections 7.2, 7.3 or 7.4 of CAN/CGA B149

Installation Codes, and applicable provisions of the local

building codes. Special conditions created by mechanical

exhausting of air and fireplaces must be considered to avoid

unsatisfactory furnace operation.

Furnace locations may be in “confined space” or “unconfined

space”. Unconfined space is defined in Table 2 and Figure 6.

These spaces may have adequate air by infiltration to pro-

vide air for combustion, ventilation, and dilution of flue

gases. Buildings with tight construction (for example,

weather stripping, heavily insulated, caulked, vapor barrier,

etc.), may need additional air provided as described for con-

fined space.

Confined spaces are installations with less than 50 cu. ft. of

space per 1000 BTU/hr input from all equipment installed.

Air for combustion and ventilation requirements can be

supplied from inside the building as in Figure 8 or from the

outdoors, as in Figure 9.

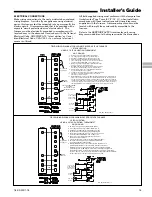

1. All air from inside the building as in Figure 8: The

confined space shall be provided with two permanent

openings communicating directly with an additional

room(s) of sufficient volume so that the combined volume

of all spaces meets the criteria for an unconfined space.

The total input of all gas utilization equipment installed

in the combined space shall be considered in making this

determination. Refer to Table 3, for minimum open

areas required.

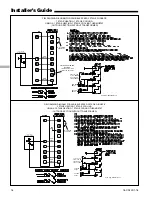

2. All air from outdoors as in Figure 9: The confined space

shall be provided with two permanent openings, one

commencing within 12 inches of the top and one com-

mencing within 12 inches of the bottom of the enclosure.

The openings shall communicate directly, or by ducts,

with the outdoors or spaces (crawl or attic) that freely

communicate with the outdoors. Refer to Table 3, for

minimum open areas required.

3. The following types of installations will

require

use of

OUTDOOR AIR for combustion, due to chemical

exposures:

* Commercial buildings

* Buildings with indoor pools

* Furnaces installed in commercial laundry rooms

* Furnaces installed in hobby or craft rooms

* Furnaces installed near chemical storage areas.

Exposure to the following substances in the combus-

tion air supply will also require OUTDOOR AIR for

combustion:

* Permanent wave solutions

* Chlorinated waxes and cleaners

* Chlorine based swimming pool chemicals

* Water softening chemicals

* Deicing salts or chemicals

* Carbon Tetrachloride

* Halogen type refrigerants

* Cleaning solvents (such as perchloroethylene)

* Printing inks, paint removers, varnish, etc.

* Hydrochloric acid

* Cements and glues

* Antistatic fabric softeners for clothes dryers

* Masonry acid washing materials

TABLE 2

MINIMUM AREA IN SQUARE FEET

FOR UNCONFINED SPACE INSTALLATIONS

FURNACE

MAXIMUM BTUH

INPUT RATING

WITH 8 FT. CEILING

MINIMUM AREA IN SQUARE

FEET OF UNCONFINED SPACE

60,000

80,000

100,000

120,000

140,000

375

500

625

750

875