12

18-CD20D1-18

Installer’s Guide

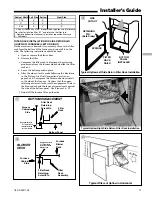

RETURN AIR FILTERS FOR UPFLOW FURNACE

IN HORIZONTAL CONFIGURATION

When the Upflow Furnace is installed in the horizontal

configuration, the return air filters must be installed exterior

to the cabinet. Remote filter grilles may be used for home-

owner convenience or the filters may be installed in the duct

work upstream of the furnace. See Figure 21.

BLOWER DOOR/HINGE REMOVAL

If clearance or other problems create a problem in using the

tilting door, the blower door hinge may be removed without

creating any problems with the seal of the furnace. To

remove the blower door, tilt the door forward 2 to 3 inches

and pull up. To remove the tilt feature, simply remove the

lower hinge as shown in Figure 22. The bottom of the blower

door will catch in the bottom of the furnace front channel for

door replacement.

REAR

SIDE

CUT

-OUT

ALTERNATE FILTER

CLIPS LOCATION

d

Door Hinge Removed

Airf low

s

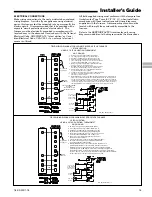

ALTERNATE UPFLOW

FILTER CLIP / BRACKET INSTALLATION

1. Determine the location to be used. The furnace cabinet

has dimples for location of the alternate furnace clips

(

Side return only

). Pre-drill clearance holes with a

3/16" drill. Bottom return holes are pre-drilled.

2. Install the clips in front and rear of the desired location

using the screws provided. The filter clip with the leaf

spring mounts in the rear of the cabinet.

UNIT

SIZE

RETURN AIR

BOTTOM

SIDE

17-1/2"

DO NOT CUT

DO NOT CUT

21"

DO NOT CUT CUT ON LINE

24-1/2"

DO NOT CUT CUT ON LINE

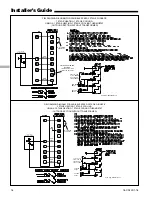

INSTALLING THE FILTER

The filter may need to be cut to fit the unit depending on the

location of the return air filter.

A score line and the words “CUT HERE” are located on the

end of the filter. If your application requires cutting the

filter, do so as indicted by the score mark.

Airflow

Airflow

f

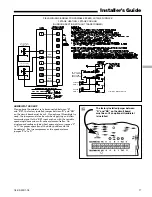

TYPICAL DOWNFLOW FURNACE

RETURN AIR FILTER INSTALLATIONS

Two filters are factory supplied for each downflow furnace.

These furnaces require high velocity type air filters. Down-

flow furnace filters must be located outside the furnace

cabinet. Typical installations are shown in Figure 24. Tables

5 and 6 provide information for installation of the filter

retaining brackets shipped with downflow furnaces.