Operating Principles

General Requirements

Operation and maintenance information for models

CVHE, CVHF, CVHG are covered in this section. This

includes both 50 and 60 Hz centrifugal chillers equipped

with the AdaptiView UC800 control system. Please note

that information pertains to all chiller types unless differ-

ences exist in which case the sections are broken down

by chiller type as applicable and discussed separately.

By carefully reviewing this information and following the

instructions given, the owner or operator can successful-

ly operate and maintain a CenTraVac unit. If mechanical

problems do occur, however, contact a qualified service

organization to ensure proper diagnosis and repair of

the unit.

Cooling Cycle

When in the cooling mode, liquid refrigerant is distrib-

uted along the length of the evaporator and sprayed

through small holes in a distributor (i.e., running the

entire length of the shell) to uniformly coat each evapo-

rator tube. Here, the liquid refrigerant absorbs enough

heat from the system water circulating through the evap-

orator tubes to vaporize. The gaseous refrigerant is then

drawn through the eliminators (which remove droplets

of liquid refrigerant from the gas) and first stage variable

inlet guide vanes, and into the first stage impeller.

Note: Inlet guide vanes are designed to modulate the

flow of gaseous refrigerant to meet system capacity

requirements; they also pre-rotate the gas, allowing it

to enter the impeller at an optimal angle that maximizes

efficiency at all load conditions.

CVHE, CVHG 3-Stage Compressor

Compressed gas from the first-stage impeller flows

through the fixed, second-stage inlet vanes and into

the second-stage impeller. Here, the refrigerant gas is

again compressed, and then discharged through the

third-stage variable guide vanes and into the third stage

impeller.

Once the gas is compressed a third time, it is discharged

into the condenser. Baffles within the condenser shell

distribute the compressed refrigerant gas evenly across

the condenser tube bundle.

Cooling tower water circulated through the condenser

tubes absorbs heat from the refrigerant, causing it to

condense. The liquid refrigerant then passes through

orifice plate and into the economizer.

The economizer reduces the energy requirements of

the refrigerant cycle by eliminating the need to pass all

gaseous refrigerant through three stages of compression

(see

). Notice that some of the liquid

refrigerant flashes to a gas because of the pressure drop

created by the orifice plates, thus further cooling the liq-

uid refrigerant. This flash gas is then drawn directly from

the first and second stages of the economizer into the

third-and second-stage impellers of the compressor, re-

spectively. All remaining liquid refrigerant flows through

another orifice plate to the evaporator.

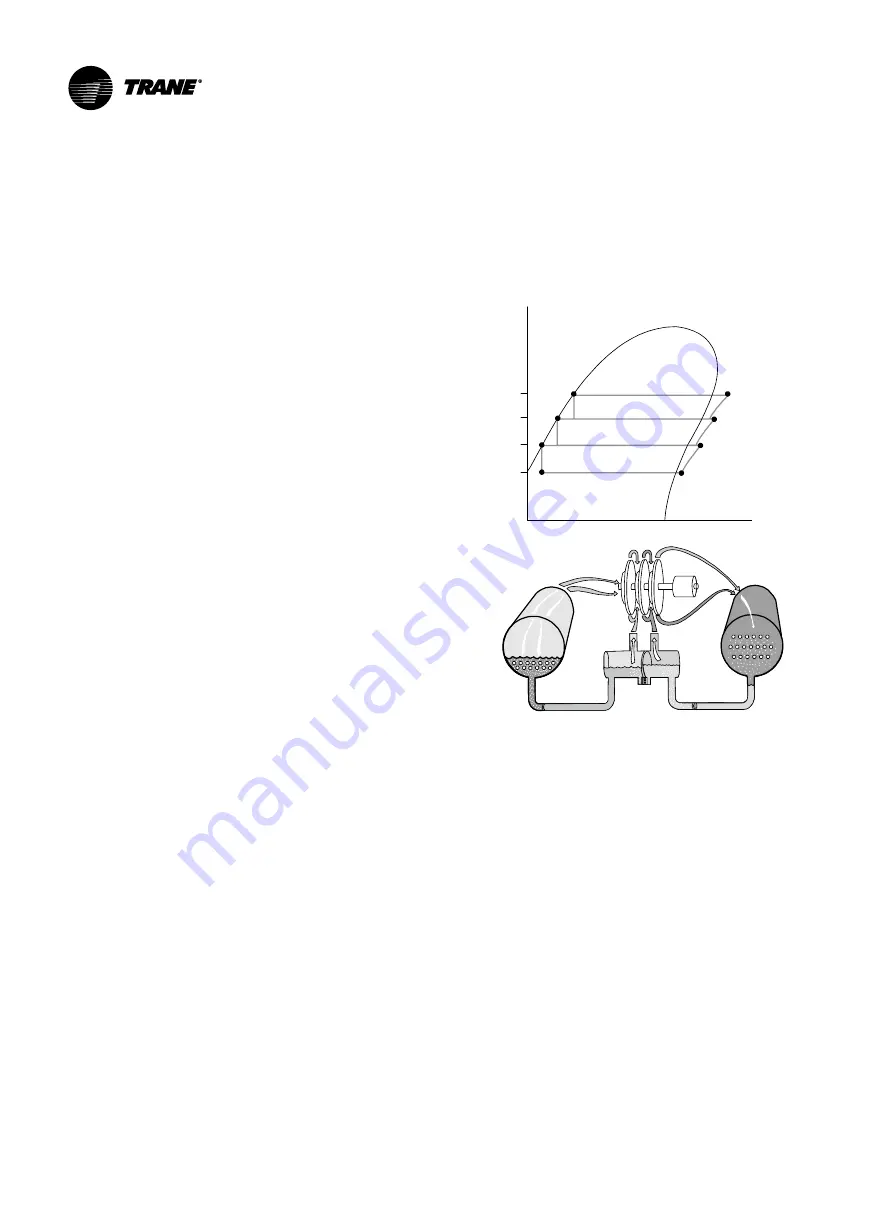

Figure 24. Pressure enthalpy curve 3 stage

condenser

2

3

evaporator

4

P

1

P

3

P

2

P

4

Pressure

(PSI

)

compressor

3rd stage)

high side economizer

low side economizer

compressor

compressor

(2nd stage)

5

6

(1st stage)

7

8

1

Figure 25. Refrigerant flow 3 stage

CVHF 2-Stage Compressor

Compressed gas from the first-stage impeller is dis-

charged through the second-stage variable guide vanes

and into the second-stage impeller. Here, the refrigerant

gas is again compressed, and then discharged into the

condenser. Baffles within the condenser shell distrib-

ute the compressed refrigerant gas evenly across the

condenser tube bundle. Cooling tower water, circulated

through the condenser tubes, absorbs heat from the

refrigerant, causing it to condense. The liquid refrigerant

then flows out of the bottom of the condenser, passing

through an orifice plate and into the economizer.

The economizer reduces the energy requirements of

the refrigerant cycle by eliminating the need to pass all

gaseous refrigerant through both stages of compression

(see

). Notice that some of the liquid

refrigerant flashes to a gas because of the pressure drop

created by the orifice plate, thus further cooling the liq-

uid refrigerant. This flash gas is then drawn directly from

the economizer into the second-stage impellers of the

compressor. All remaining liquid refrigerant flows out of

the economizer, passes through another orifice plate and

into the evaporator.

52

RELEASED 10/Mar/2020 06:59:20 GMT