the hinges to keep them centered. Close the hinge gap to 1/32"

or less – it is better to have a

slight gap to avoid inadvertently

gluing the control surfaces together. Remove the pins if you have

used any.

❍

4. Add 6 drops of thin CA to the center of all the hinges on

both the top and the bottom.

❍

5. Join the rudder to the fin using the same procedures.

❍

6. Clean the aileron torque rod arms with rubbing alcohol to

remove skin oils or smeared petroleum jelly.

❍

7. Prepare the hinge slots in the ailerons the same way as the

tail surfaces.

❍

8. Use a toothpick to pack the torque rod holes in the ailerons

with 30-minute epoxy, then install the ailerons with the hinges and

thin CA using the methods we’ve described. Wipe away the epoxy

that is squeezed out of the ailerons with a paper towel and alcohol.

Do not use accelerator on any of the hinges. Do not glue the

hinges with anything but thin CA and do not attempt to glue

one half of the hinge at a time with medium or thick CA. They

will not be properly secured and the controls could separate

while the model is in flight.

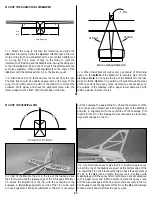

THE CA WICKS

ALONG THE "TUNNELS"

TO THE ENTIRE

HINGE SURFACE

ASSEMBLE, THEN APPLY 6 DROPS

OF THIN CA TO CENTER

OF HINGE, ON BOTH SIDES

45

FINAL CONTROL HOOKUPS

❍

1. Install the Elevator and Rudder small nylon control horns in

line with the pushrod exits as shown on the plans. Hold the horns

in position and mark the location of the mounting holes. Drill

3/32" mounting holes through the marks. Wick two to three drops

of Thin CA into the holes to harden the underlying balsa. The

horns are screwed in place using 2-56 x 5/8" machine screws and

nylon nut plates. Do not tighten the screws as to crush the

underlying balsa.

❍

2. Mount the servos into the main servo tray oriented as shown

on the fuselage plan top view. Mount the aileron servo in the

aileron tray. Since the main servo tray is adjustable fore and aft

for small CG corrections, do not glue it in until told to do so.

❍

3. For easy setup and good control response, we recommend

you start off using servo horns resembling those on the plans. The

Rudder, Throttle and Elevator horns are made using the large four

armed horns. The aileron servo used the smaller, six armed horn

to provide differential throw. In this case it will cause the ailerons

to deflect “up” more than the deflect “down.”

❍

4. Make the Rudder and Elevator pushrods: (Use the sketch on

the plans to assist in making the pushrods. Both the Elevator and

Rudder are made using the same sketch.)

A. Locate the two 36" threaded rods. Cut each of the threaded

rods so there are two 10" rods with threads on one end. Save

the remaining wire, as it will be used in a couple of minutes.

B. Locate the two 1/4" x 16" hardwood dowels. Cut them to a

length of 14". Drill a 5/64" hole 1" from the end of the dowel.

A total of four holes need to be drilled.

C. Using a sharp hobby knife, cut a notch from the hole to the

end of the dowel as was done with the ailerons to provide

access for the torque rods.

D. Bend one end of the threaded rods, and one end of the

remaining wire, 1/4" from the non-threaded end. Insert the

bend into the hole drilled in the dowel.

46