❍

2. Sheet the bottom of the other wing panel in the same manner.

❍

3. Draw a line connecting the sides of the servo tray mounts

and use a sharp hobby knife to remove the sheeting to allow for

the installation of the servo.

❍

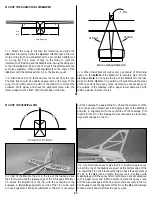

4. Cut a couple of leftover 1/16" sheets and glue them inside of

the wing as shown, to support and strengthen the sheeting around

the servo cut out.

❍

5. Using the remaining sheet of 1/16" x 3" x 36" balsa, sheet

the upper side of the wing. Sheet from the front (LE) to the rear

(TE). Again, work slowly to make sure all the pieces fit well with

the least amount of gaps. R-3 may be slightly higher than the

leading edge. Just glue the sheeting even with the LE and we will

sand everything smooth later.

❍

6. Use leftover balsa to fill areas where there may be large

openings or gaps. An example would be at the ends of the

dihedral braces and the R-3 ribs. Using balsa will mean using less

filler later.

31

FINAL ASSEMBLY

❍

1. Insert the 1/4" x 5-1/8" Hardwood Dowels into the holes

drilled earlier during the fuselage assembly. The holes can be

enlarged in the fuselage with a round file or drill bit if the fit is

too tight.

❍

2. Test fit the balsa die-cut 1/8" Front and Rear Windows into

position. Sand as necessary to achieve the best fit. Glue the

windows using medium CA.

❍

3. Align the wing and attach it with two #64 rubber bands. Use

care not to crush the trailing edge of the wing during this process.

Fit the wing on the fuselage wing saddle. Trim the aft edge of the

wing trailing edge at the center with a sanding block if necessary

for a good fit.

A

A

32