– 96 –

Concealed Duct High Static Pressure

Installation Manual

Concealed Duct High Static Pressure

Installation Manual

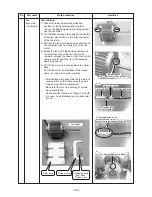

Procedure

6

When settings have been completed, push

button to

determine the settings.

When

button is pushed, “SETTING” flashes and then

the display content disappears and the air conditioner

enters the normal stop mode. (While “SETTING” is flashing,

no operation of the remote controller is accepted.)

n

Filter sign setting

According to the installation condition, the filter sign term

(Notification of filter cleaning) can be changed.

Follow to the basic operation procedure

(

1

→

2

→

3

→

4

→

5

→

6

).

• For the CODE No. in

Procedure

3

, specify [01].

• For the [SET DATA] in

Procedure

4

, select the SET

DATA of filter sign term from the following table.

n

To secure better effect of

heating

When it is difficult to obtain satisfactory heating due to

installation place of the indoor unit or structure of the

room, the detection temperature of heating can be raised.

Also use a circulator, etc. to circulate heat air near the

ceiling.

Follow to the basic operation procedure

(

1

→

2

→

3

→

4

→

5

→

6

).

• For the CODE No. in

Procedure

3

, specify [06].

• For the set data in

Procedure

4

, select the SET DATA of

shift value of detection temperature to be set up from the

table below.

n

Power saving mode

1. Push

button for at least four seconds when the

air conditioner is not working.

flashes.

Indicates CODE No. “C2.”

2. Select an indoor unit to be set by pushing

(left side of the button).

Each time you push the button, unit numbers change

as follows:

UNIT No.

1-1

UNIT No.

1-2

UNIT No.

1-4

UNIT No.

1-3

The fan of the selected unit runs.

3. Adjust the power save setting by pushing

TIME

/

buttons.

Each push of the button changes the power level by 1%

within the range from 100% to 50%.

∗

The factory default is 75%.

Setting of power level

in power saving mode

4. Determine the setting by pushing

button.

5. Push

button to complete the setting.

n

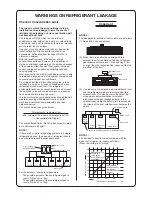

Remote controller switch monitoring function

This function is available to call the service monitor mode from the remote controller during a test run to acquire

temperatures of sensors of the remote controller, indoor unit, and outdoor unit.

SET DATA

0000

0001

0002

0003

0004

Filter sign term

None

150H

2500H (Factory default)

5000H

10000H

SET DATA

0000

0001

0002

0003

0004

0005

0006

Detection temperature shift value

No shift

+1°C

+2°C (Factory default)

+3°C

+4°C

+5°C

+6°C

1

3

4

2

1. Push and

buttons simultaneously for at least 4 seconds to call the service monitor mode.

The service monitor indicator lights up and the header indoor unit number is displayed first.

CODE No.

is also displayed.

2. Pushing TEMP.

/

buttons, select the number of sensor, etc. (CODE No.) to be monitored.

(See the following table.)

3. Pushing

(left side of the button), select an indoor unit to be monitored.

The sensor temperatures of indoor units and their outdoor unit in the control group are displayed.

4. Push

button to return to the normal display.

Indoor unit data

CODE No.

Data name

01

Room temperature (remote controller)

02

Indoor unit intake air temperature (TA)

03

Indoor unit heat exchanger (coil)

temperature (TCJ)

04

Indoor unit heat exchanger (coil)

temperature (TC)

F3

Indoor unit fan cumulative operating hours

(× 1 h)

Outdoor unit data

CODE No.

Data name

60

Outdoor unit heat exchanger (coil)

temperature (TE)

61

Outside air temperature (TO)

62

Compressor discharge temperature (TD)

63

Compressor suction temperature (TS)

64

—

65

Heatsink temperature (THS)

6A

Operating current (× 1/10)

F1

Compressor cumulative operating hours

(× 100)

– 29 –

– 30 –