51

Chec

k code

Main

remote

contr

oller

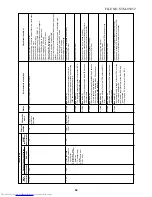

P07

P12

P13

P15

P17

P19

Outdoor 7-segment displa

y

Chec

k code

Sub-code

P07

0

1

:

Compressor

1 side

0

2

:

Compressor

2 side

——

P13

—

P15

0

1

:

TS condition

02:

TD

condition

P17

—

P19

Detected

outdoor unit No

.

AI-NET

central contr

ol

remote contr

oller

1C

11

47

AE

AE

bb

8

Detected

position

IPDU

I/F

Indoor

I/F

I/F

I/F

I/F

I/F

Check code

name

Heat sink

o

v

erheat error

Indoor f

a

n

motor error

Outdoor liquid

bac

k detection

error

Gas leak

detection

(TS1 condition)

Gas leak

detection

(TD condition)

Discharge

temp TD2

error

4-w

a

y

v

alv

e

oper

ation error

Status

All stop

Corresponding

unit only stops

.

All stop

All stop

All stop

All stop

All stop

Err

or detection condition

IGBT b

uilt-in temp sensor (TH) w

as o

v

erheated.

•

The v

alue of motor speed de

viated from

target v

alue w

as detected f

or cer

tain time

.

•

O

v

er-current protection oper

ated.

<In cooling>

While the system is oper

ating in COOL mode

, a

high pressure v

alue w

as detected in f

ollo

w

e

r

unit in which compressor did not oper

ate

.

<In heating>

While the system is oper

ating in HEA

T mode

,

outdoor PMV of which opening deg

ree w

a

s

100p or less f

or a cer

tain time

.

Suction temp e

xceeded the judgment standard

temp f

or 10 min

utes or more

.

<TS err

or judgment standar

d temperature>

In cooling oper

ation:

60

°C or higher

In heating oper

ation:

40

°C or higher

Discharge temper

ature

TD1 or

TD2 w

a

s

contin

uously 108

°C or higher f

or 10 min

utes

.

Discharge temper

ature (TD2) e

xceeded 115

°C.

When abnor

mal refr

iger

ating cycle data w

a

s

detected in heating

Chec

k item (position)

•

Chec

k po

w

er v

oltage

.

•

Chec

k outdoor f

an system error

.

•

Chec

k clogging of heat sink cooling duct.

•

Chec

k fixation betw

een IGBT and heat sink.

(Chec

k scre

wing and contact.)

•

Chec

k IPDU error

.(IGBT b

uilt-in temp sensor (TH) error)

•

Chec

k connection of f

an connector and wir

ing.

•

Chec

k f

an motor error

.

•

Chec

k indoor P

.C

. board error

.

•

Chec

k influence of outside air control.

•

Chec

k indoor type code (DN=10) and the capacity code (DN=11).

•

Chec

k full close oper

ation of outdoor PMV (1, 2).

•

Chec

k Pd and Ps sensor error

.

•

Chec

k clogging of SV2 circuit.

•

Chec

k clogging of balance pipe

.

•

Chec

k clogging of SV3B circuit.

•

Chec

k outdoor P

.C

. board (I/F) error

.

•

Chec

k capillar

y clogging of oil retur

n circuit from oil separator

.

•

Chec

k leakage of chec

k v

alv

e of the main discharge pipe

.

•

Chec

k refr

iger

ant shor

tage

.

•

Chec

k full open of outdoor ser

vice v

alv

es (gas side

, liquid side).

•

Chec

k outdoor PMV clogging (PMV1, 2).

•

Chec

k char

acter

istics of

TS1 sensor resistance v

alue

.

•

Chec

k 4-w

a

y

v

alv

e error

.

•

Chec

k leakage of SV4 circuit.

•

Chec

k refr

iger

ant shor

tage

.

•

Chec

k outdoor PMV clogging (PMV1, 2).

•

Chec

k char

acter

istics of

TD1,

TD2 sensor resistance v

alue

.

•

Chec

k indoor air filter clogging.

•

Chec

k pipe clogging.

•

Chec

k SV4 circuit (V

alv

e leakage

, misinstallation)

•

Chec

k full opening of outdoor ser

vice v

alv

es

(gas side

, liquid side).

•

Chec

k clogging of outdoor PMV (PMV1, 2).

•

Chec

k char

acter

istics of

TD2 sensor resistance v

alue

.

•

Chec

k 4-w

a

y

v

alv

e error

.

•

Chec

k leakage of SV42 circuit.

•

Chec

k SV4 circuit.

(Miscab

ling and misinstallation of SV41 and SV42)

•

Error of 4-w

a

y

v

alv

e error

•

Chec

k coil error and connector connection of 4-w

a

y v

alv

e

.

•

Chec

k char

acter

istics of

TS1/TE1 sensor resistance v

alue

.

•

Chec

k char

acter

istics of Pd, Ps pressure sensor output v

oltage

.

•

Chec

k misconnection of

TE1 and

TL sensors

.

FILE NO. SVM-05052

Содержание MMK-AP0072H

Страница 125: ...TOSHIBA CARRIER CORPORATION ...