G014973

1

2

3

Figure 46

1.

Opposing blade edge, in position for measuring

2.

Level surface

3.

Second measured distance between blade and surface (B)

WARNING

A blade that is bent or damaged could break

apart and could seriously injure or kill you or

bystanders.

•

Always replace bent or damaged blade with

a new blade.

•

Never file or create sharp notches in the

edges or surfaces of blade.

A. If the difference between A and B is greater

than 1/8 inch (3mm) replace the blade with a

new blade. Refer to Removing the Blades and

Installing the Blades.

Note:

If a bent blade is replaced with a new one

and the dimension obtained continues to exceed

1/8 inch (3mm), the blade spindle could be bent.

Contact an Authorized Toro Dealer for service.

B. If the variance is within constraints, move to the

next blade..

Repeat this procedure on each blade.

Removing the Blades

The blades must be replaced if a solid object is hit,

if the blade is out of balance, or the blade is bent.

To ensure optimum performance and continued

safety conformance of the machine, use genuine Toro

replacement blades. Replacement blades made by other

manufacturers may result in non-conformance with

safety standards.

Hold the blade end using a rag or thickly-padded glove.

Remove the blade bolt, curved washer, blade stiffener,

and blade from the spindle shaft (Figure 47).

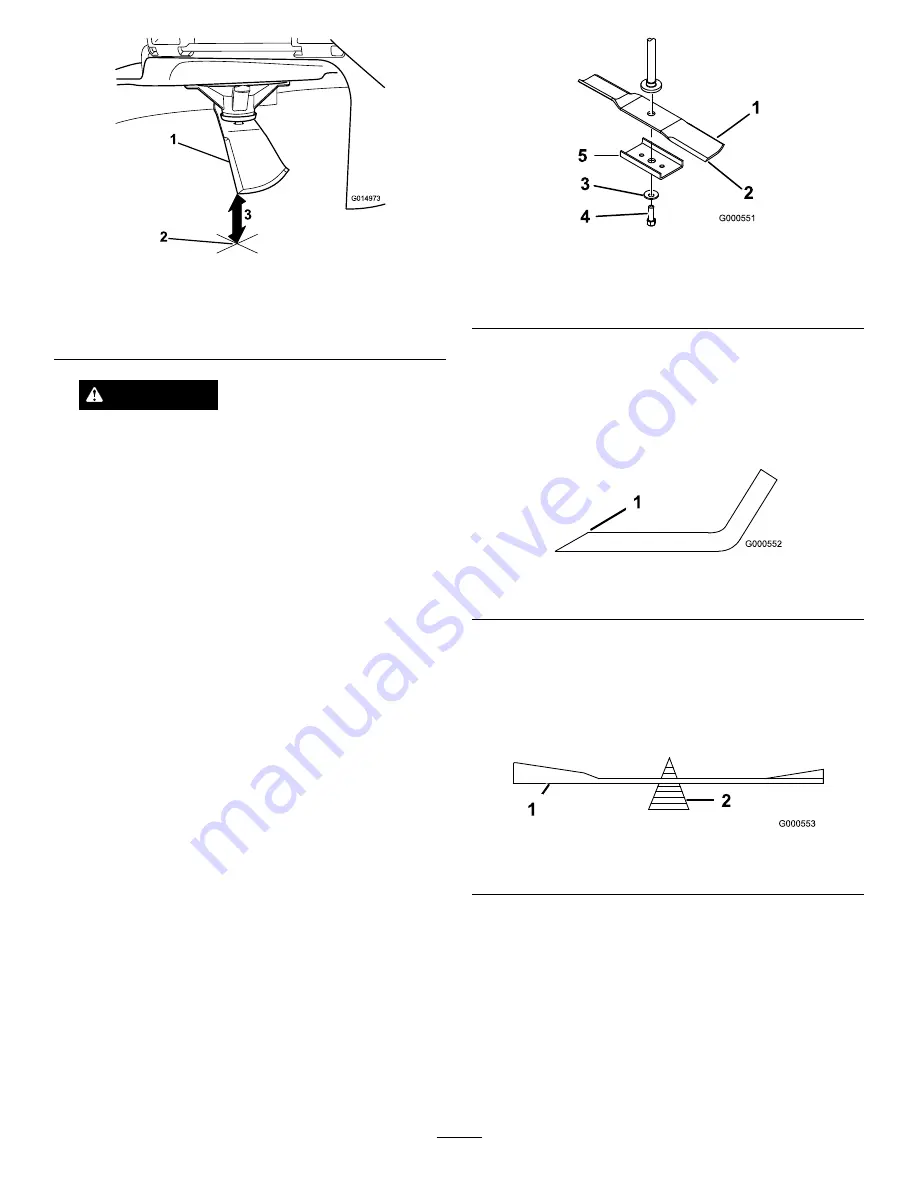

Figure 47

1.

Sail area of blade

4.

Blade bolt

2.

Blade

5.

Blade stiffener

3.

Curved washer

Sharpening the Blades

1. Use a file to sharpen the cutting edge at both ends

of the blade (Figure 48). Maintain the original angle.

The blade retains its balance if the same amount of

material is removed from both cutting edges.

Figure 48

1.

Sharpen at original angle

2. Check the balance of the blade by putting it on a

blade balancer (Figure 49). If the blade stays in a

horizontal position, the blade is balanced and can be

used. If the blade is not balanced, file some metal off

the end of the sail area only (Figure 48). Repeat this

procedure until the blade is balanced.

Figure 49

1.

Blade

2.

Balancer

Installing the Blades

1. Install the blade onto the spindle shaft (Figure 47).

Important:

The curved part of the blade must

be pointing upward toward the inside of the

mower to ensure proper cutting.

2. Install the blade stiffener, the curved washer (cupped

side toward the blade) and the blade bolt (Figure 47).

3. Torque the blade bolt to 35-65 ft-lb (47-88 N-m).

38

Содержание TimeCutter MX 4260

Страница 10: ...119 8874 1 Low speed 2 High speed 10 ...

Страница 11: ...121 0772 1 Fast 4 Choke 2 Continuous variable setting 5 Power take off PTO Blade control switch 3 Slow 11 ...

Страница 48: ...Schematics g017655 Electrical Diagram Rev A 48 ...

Страница 49: ...Notes 49 ...

Страница 50: ...Notes 50 ...

Страница 51: ...Notes 51 ...