Reelmaster 7000

Page 5 -- 28

Electrical System

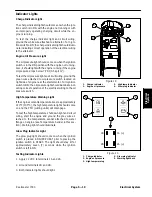

Cutting Unit Position Sensor

The cutting unit position sensor is a normally open prox-

imity sensor that is located on the traction unit frame

(Fig. 36). The sensing plate that closes the sensor is a

gusset on the front right cutting unit (#5) lift arm.

When the cutting units are lowered, the gusset on the lift

arm is located near the position sensor and the sensor

closes. This closed sensor provides an input for the TEC

controller to allow the lowered cutting units to operate.

Sensor Testing

1. Park machine on a level surface, lower cutting units,

stop engine and engage parking brake.

2. Before disconnecting the cutting unit position sensor

for testing, the sensor and its circuit wiring should be

tested as a TEC input with the Diagnostic Display (see

Diagnostic Display in the Troubleshooting section of this

chapter). If the Diagnostic Display verifies that the posi-

tion sensor and circuit wiring

are

functioning correctly,

no further sensor testing is necessary. If, however, the

Display determines that the position sensor and circuit

wiring

are not

functioning correctly, proceed with test.

3. Turn ignition switch to the ON position and check

LED on cable end of cutting unit position sensor (Fig.

36). LED

should be

illuminated when the cutting units

are fully lowered. The LED

should not be

illuminated

when the cutting units are raised above the turn--around

position.

4. If the position sensor LED did not function correctly:

A. Make sure that the cutting unit position sensor is

properly adjusted (see Cutting Unit Position Sensor

in the Adjustments section of this chapter). If neces-

sary, adjust sensor and return to step 2 above.

B. Make sure ignition switch is OFF and disconnect

the cutting unit position sensor connector from ma-

chine wire harness.

C. Verify that the machine wire harness connector

terminal for black wire is closed (continuity) to

ground.

D. Turn ignition switch to the ON position (do not

start engine) and verify with a multimeter that ma-

chine wire harness connector terminal for pink wire

has system voltage (12 VDC) present.

E. If black wire is closed to ground, pink wire has

system voltage present and sensor LED did not func-

tion, replace cutting unit position sensor. Adjust sen-

sor after installation (see Cutting Unit Position

Sensor in the Adjustments section of this chapter).

5. If the cutting unit position sensor tests correctly and

a circuit problem still exists, check wire harness (see

Electrical Schematic and Wire Harness Drawings in

Chapter 9 -- Foldout Drawings).

6. Make sure that cutting unit position sensor is con-

nected to wire harness when testing is complete.

1. Position sensor

2. Sensor cable

3. Lift arm (#5)

Figure 36

3

1

2

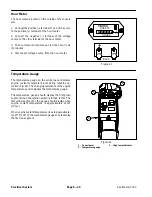

Figure 37

CUTTING UNIT LOCATIONS

#4

#1

#5

#3

#2

Содержание Reelmaster 7000

Страница 2: ...Reelmaster 7000 This page is intentionally blank ...

Страница 4: ...Reelmaster 7000 This page is intentionally blank ...

Страница 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Страница 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Страница 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Страница 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Страница 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Страница 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Страница 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Страница 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Страница 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Страница 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Страница 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Страница 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Страница 221: ...Reelmaster 7000 Page 6 7 Axles Planetaries and Brakes This page is intentionally blank Axles Planetaries and Brakes ...

Страница 227: ...Reelmaster 7000 Page 6 13 Axles Planetaries and Brakes This page is intentionally blank Axles Planetaries and Brakes ...

Страница 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Страница 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Страница 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Страница 287: ...Reelmaster 7000 DPA Cutting Units Page 8 23 This page is intentionally blank DPA Cutting Units ...

Страница 291: ...Reelmaster 7000 DPA Cutting Units Page 8 27 This page is intentionally blank DPA Cutting Units ...

Страница 295: ...Reelmaster 7000 DPA Cutting Units Page 8 31 This page is intentionally blank DPA Cutting Units ...

Страница 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Страница 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Страница 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Страница 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Страница 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...