Drive System

Maintenance

Checking the Tire Air

Pressure

Service Interval:

Before each use or daily

Important:

Maintain the recommended pressure

in all tires to ensure a good quality of cut and

proper machine performance. Do not underinflate

the tires.

1.

Prepare the machine for maintenance; refer to

Preparing for Maintenance (page 40)

.

2.

Measure the tire air pressure.

Note:

The correct air pressure in the tires is 83

to 103 kPa (12 to 15 psi).

3.

If needed add air to or remove air from the tire.

4.

Repeat steps

and

at the other tires.

Checking the Torque of the

Wheel Nuts

Service Interval:

After the first hour

After the first 10 hours

Every 250 hours

WARNING

Failure to maintain proper torque of the wheel

nuts could result in personal injury.

Maintain the proper torque on the wheel nuts.

1.

Prepare the machine for maintenance; refer to

Preparing for Maintenance (page 40)

.

2.

Torque the wheel nuts to 94 to 122 N∙m (70 to

90 ft-lb).

Adjusting the Traction

Drive for Neutral

Important:

The machine must not move when

the traction pedal is released (in the N

EUTRAL

position). If the machine moves, adjust traction

pump as follows:

1.

Prepare the machine for maintenance; refer to

Preparing for Maintenance (page 40)

.

2.

Jack up the front of the machine until the both

front tires are off the ground, and support the

machine with jack stands, refer to

and

Specifications (page

.

3.

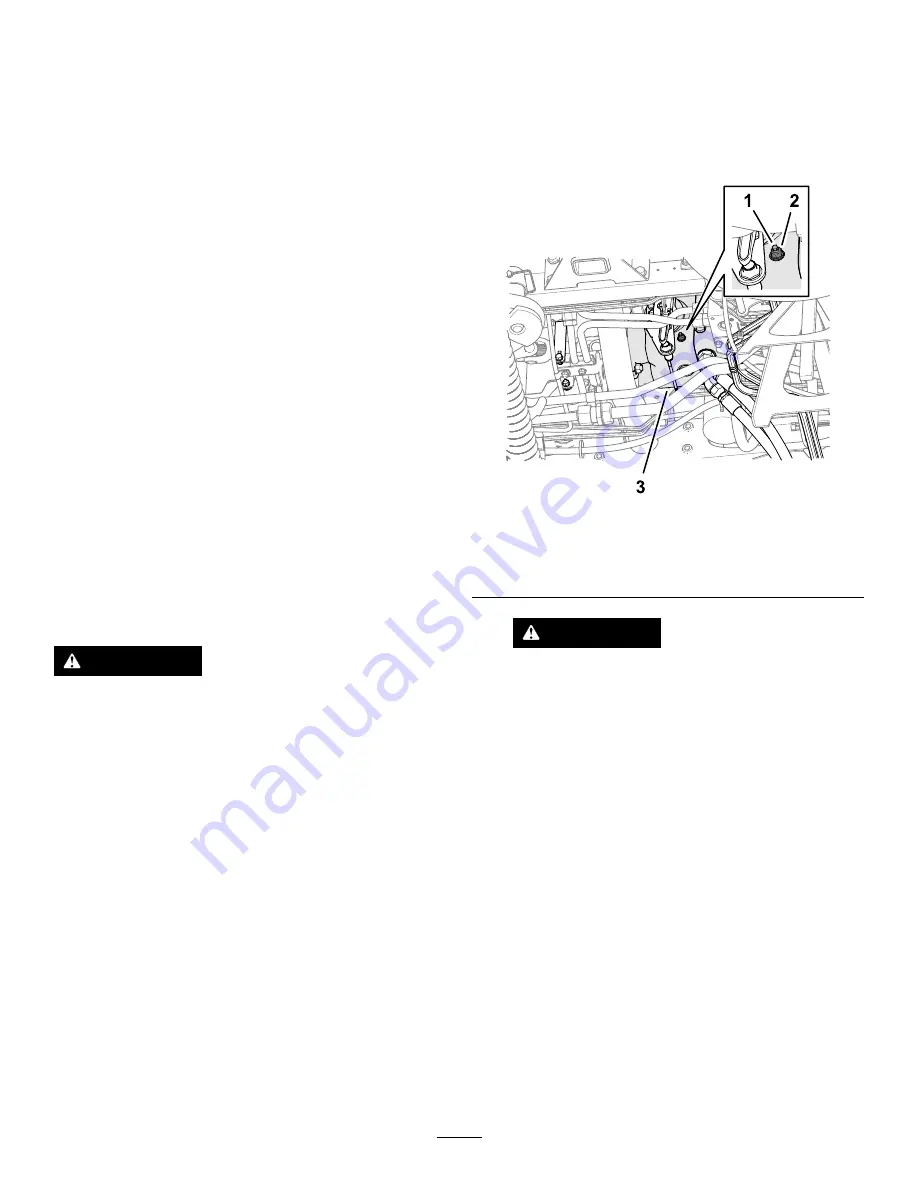

From the bottom of the machine and at the right

side of the traction pump, loosen the locknut

that secures the neutral return-adjustment screw

(

).

g375898

Figure 90

1.

Neutral return-adjustment

screw

3.

Traction pump

2.

Locknut

WARNING

The engine must be running so the final

adjustment of the traction adjustment

cam can be performed. This could cause

personal injury.

Keep hands, feet, face, and other body

parts away from the muffler, other hot

parts of the engine, and any rotating

parts.

4.

Start the engine and release the parking brake.

5.

Rotate the neutral return-adjustment screw in

either direction until the wheels stop rotating.

6.

Torque the locknut to 22 N∙m (16 ft-lb).

7.

Shut off the engine and remove the key.

8.

Remove the jack stands, and lower the machine

to the ground.

9.

Test drive the machine to ensure that it does not

move when the traction pedal is in the N

EUTRAL

position.

52

Содержание Reelmaster 5610

Страница 68: ......