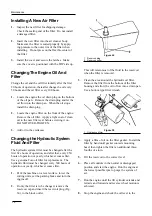

Installing A New Air Filter

1.

Inspect the new filter for shipping damage.

Check the sealing end of the filter. Do not install

a damaged filter.

2.

Insert the new filter into the air cleaner body.

Make sure the filter is sealed properly by apply-

ing pressure to the outer rim of the filter when

installing. Do not press on the flexible center of

the filter.

3.

Install the cover and secure the latches. Make

sure the cover is positioned with the TOP side up.

Changing The Engine Oil And

Filter

Change the oil and the oil filter initially after the first

20 hours of operation, thereafter change the oil every

50 hours and the oil filter every 100 hours.

1.

Locate the engine the oil drain plug on the bottom

of the oil pan.. Remove the drain plug and let the

oil flow into the drain pan. When the oil stops,

install the drain plug.

2.

Locate the engine filter on the front of the engine.

Remove the oil filter. Apply a light coat of clean

oil to the new filter seal before screwing it on.

DO NOT OVER-TIGHTEN.

3.

Add oil to the crankcase.

Changing the Hydraulic System

Fluid And Filter

The hydraulic system filter must be changed after the

first five hours of operation, and after that, every 250

hours of operation or yearly, whichever comes first.

Use a genuine Toro oil filter for replacement. The

hydraulic fluid must be changed every 500 hours of

operation or yearly, whichever comes first.

1.

Park the machine on a level surface, lower the

cutting units, set the parking brake and turn the

engine off.

2.

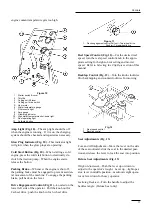

If only the filter is to be changed, remove the

reservoir cap and insert the reservoir plug (Fig.

30), to the block outlet.

Figure 29

1. Reservoir plug

2. Reservoir outlet

This will retain most of the fluid in the reservoir

when the filter is removed.

3.

Clean the area around the hydraulic oil filter.

Remove the filter from the bottom of the filter

housing and allow the oil to flow into a drain pan.

Use a bottom type filter wrench.

Figure 30

1. Hydraulic oil filter

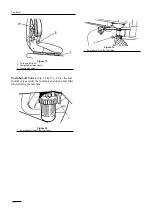

4.

Apply a film of oil on the filter gasket. Install the

filter by hand until gasket contacts mounting

head; then tighten the filter an additional three-

fourths of a turn.

5.

Fill the reservoir to the correct level.

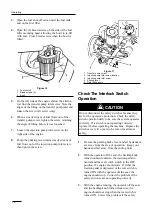

6.

Place all controls in the neutral or disengaged

position and start the engine. Run the engine at

the lowest possible rpm to purge the system of

air.

7.

Run the engine until the lift cylinder extends and

retracts and forward and reverse wheel motion is

achieved.

8.

Stop the engine and check the oil level in the

26

Maintenance

Содержание REELMASTER 2300-D

Страница 24: ...Figure 21 Figure 22 Figure 23 Figure 24 Figure 25 Figure 26 24 Maintenance ...

Страница 29: ......