22

Maintenance

Important

If the machine is on a slope, set the parking brake and chock or block the wheels to prevent the machine from

slowly rolling.

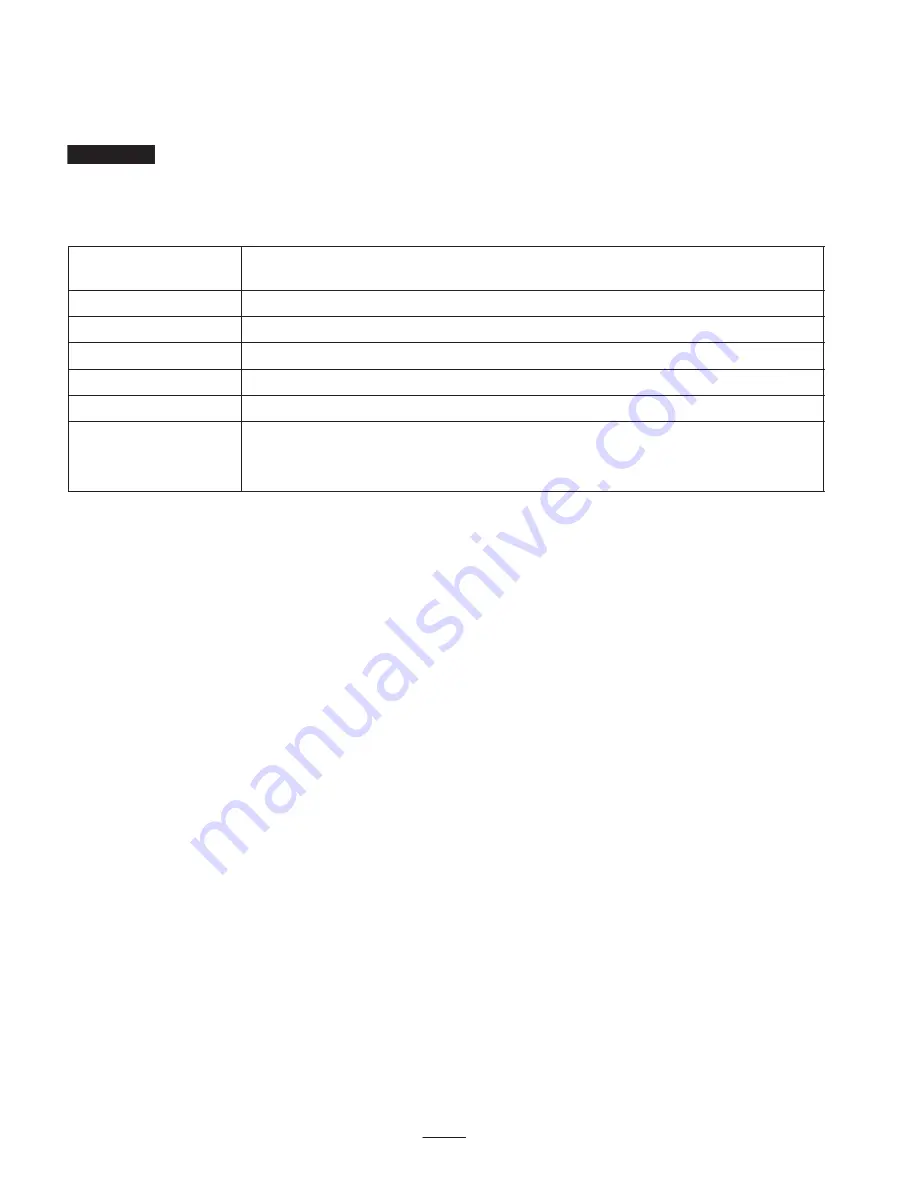

Recommended Maintenance Schedule

Maintenance Service

Interval

Maintenance Procedure

Each Use

•

Screen—clean

8 Hours

•

Bagger—clean

First 10 Hours

•

Bagger—inspect

40 Hours

•

Bagger idler arm—grease

100 Hours

•

Bagger—inspect

Storage Service

•

Belts—check for wear/cracks

•

Bagger—inspect

•

Bagger—clean

Note: Determine the left and right side of the machine from the normal operating position.

Cleaning the Screen

The screen needs to be cleaned before each use. In wet

grass it will need to be cleaned more often.

1. Disengage the PTO, set the parking brake, and chock or

block the drive wheels.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Open the bagger and hold the bagger door open. Refer

to Holding the Bagger Door Open on page 18.

4. Clean the debris from the screens.

5. Close the bagger door.

Cleaning the Bagger

The bagger needs to be cleaned after every 8 hours.

1. Wash the inside and outside of the bagger, upper tube,

lower tube, boot assembly and the underside of the

mower. Use a mild automotive detergent to remove dirt.

2. Make sure you remove matted grass from all parts.

3. After washing all parts, let them dry thoroughly.

Note: With all parts installed, start and run the machine for

a minute to assist in drying.

Checking the Bagger Belt

Check the bagger belt for wear and cracks at when storing

the bagger.

Greasing the Idler Arm

Grease the bagger belt idler arm every 40 hours.

Inspecting the Bagger

Inspect the bagger attachment after the first ten hours of

operation, and 100 hours thereafter.

1. Disengage the PTO, set the parking brake, and chock or

block the drive wheels.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Check the upper tube, lower tube, and the boot

assembly. Replace these parts if they are cracked or

broken.

4. Check the bagger, bagger frame, and screen. Replace

any parts that are cracked or broken.

5. Tighten all nuts, bolts and screws.