Greensmaster 3300/3400

Hydraulic System

Page 5 -- 59

Hydraulic System Start--up

NOTE:

When initially starting the hydraulic system with

new or rebuilt components such as motors, pumps or lift

cylinders, it is important that this start--up procedure be

used. This procedure reduces the chance of damaging

the system or its components from not purging the sys-

tem of air.

1. After the hydraulic system components have been

properly installed and if the piston pump was rebuilt or

replaced, make sure piston pump housing is at least half

full of clean hydraulic oil.

2. Make sure all hydraulic connections and lines are se-

cured tightly.

3. Make sure hydraulic reservoir is full. Add correct oil

if necessary. Drain, flush and refill hydraulic system res-

ervoir and change oil filter if component failure was se-

vere or system is contaminated.

4. After repairs, check control linkage for proper adjust-

ment, binding or broken parts.

5. Make sure the functional control lever is in the neutral

(N) position.

6. Disconnect appropriate electrical component(s) to

prevent the engine from starting:

A. On machines with gasoline engine, disconnect

both spark plug wires from spark plugs.

B. On machines with diesel engine, disconnect wire

harness electrical connector from the engine fuel

stop solenoid.

7. Turn ignition key switch and engage starter for ten

(10) seconds to prime pumps. Return ignition switch to

off and wait one (1) minute to allow starter to cool. Re-

peat step a second time.

8. Reconnect engine electrical component(s) that were

disabled in step 6 above.

9. With the functional control lever in the neutral (N)

position, start engine and run at low idle speed. The

charge pump should pick up oil and fill the hydraulic sys-

tem. If there is no indication of fill in thirty (30) seconds,

stop the engine and determine the cause.

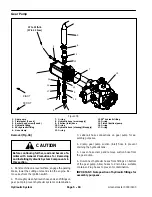

CAUTION

Be careful when operating the cutting unit reels.

Contact with the reel or other moving parts can

result in personal injury.

10.After the hydraulic system starts to show signs of fill,

accomplish the following:

A. If a reel motor was replaced or rebuilt, run the cut-

ting units at the minimum speed setting (under no

load) for ten (10) minutes in

both

directions.

B. If the gear pump was replaced or rebuilt, run the

cutting units at the minimum speed setting (under no

load) for ten (10) minutes.

C. If the piston pump or a wheel motor was replaced

or rebuilt, run the traction unit so the wheels slowly

turn for ten (10) minutes.

11.Operate the traction unit and cutting units by gradu-

ally increasing their work load to full over a ten (10) min-

ute period.

12.Stop the machine. Check reservoir and fill if neces-

sary. Check hydraulic components for leaks and tighten

any loose connections.

Hydraulic System

Содержание 04510 Greensmaster 3300 TriFlex

Страница 2: ...Greensmaster 3300 3400 This page is intentionally blank ...

Страница 4: ...Greensmaster 3300 3400 This page is intentionally blank ...

Страница 6: ...Greensmaster 3300 3400 This page is intentionally blank ...

Страница 14: ...0 09375 Greensmaster 3300 3400 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Страница 24: ...Greensmaster 3300 Page 3 6 Gasoline Engine This page is intentionally blank ...

Страница 38: ...Greensmaster 3400 Page 4 4 Diesel Engine This page is intentionally blank ...

Страница 54: ...Greensmaster 3300 3400 Hydraulic System Page 5 2 This page is intentionally blank ...

Страница 63: ...Greensmaster 3300 3400 Hydraulic System Page 5 11 This page is intentionally blank Hydraulic System ...

Страница 83: ...Greensmaster 3300 3400 Hydraulic System Page 5 31 This page is intentionally blank Hydraulic System ...

Страница 121: ...Greensmaster 3300 3400 Hydraulic System Page 5 69 This page is intentionally blank Hydraulic System ...

Страница 125: ...Greensmaster 3300 3400 Hydraulic System Page 5 73 This page is intentionally blank Hydraulic System ...

Страница 131: ...Greensmaster 3300 3400 Hydraulic System Page 5 79 This page is intentionally blank Hydraulic System ...

Страница 137: ...Greensmaster 3300 3400 Hydraulic System Page 5 85 This page is intentionally blank Hydraulic System ...

Страница 155: ...Greensmaster 3300 3400 Hydraulic System Page 5 103 This page is intentionally blank Hydraulic System ...

Страница 167: ...Greensmaster 3300 3400 Hydraulic System Page 5 115 This page is intentionally blank Hydraulic System ...

Страница 170: ...Greensmaster 3300 3400 Hydraulic System Page 5 118 This page is intentionally blank ...

Страница 172: ...Greensmaster 3300 3400 Page 6 2 Electrical System This page is intentionally blank ...

Страница 181: ...Greensmaster 3300 3400 Page 6 11 Electrical System This page is intentionally blank Electrical System ...

Страница 223: ...Greensmaster 3300 3400 Page 6 53 Electrical System This page is intentionally blank Electrical System ...

Страница 230: ...Greensmaster 3300 3400 Page 6 60 Electrical System This page is intentionally blank ...

Страница 265: ...Greensmaster 3300 3400 DPA Cutting Units Page 8 9 This page is intentionally blank DPA Cutting Units ...

Страница 279: ...Greensmaster 3300 3400 DPA Cutting Units Page 8 23 This page is intentionally blank DPA Cutting Units ...

Страница 303: ...Greensmaster 3300 3400 Groomer Page 9 13 This page is intentionally blank Groomer ...

Страница 318: ...Greensmaster 3300 3400 Page 10 2 Foldout Drawings This page is intentionally blank ...

Страница 332: ...Page 10 16 This page is intentionally blank ...