3.

While relieving the spring tension, remove the

bolt and locknut securing the spring actuator to

the bracket (

g034346

Figure 37

1.

Spring

3.

Additional hole locations

2.

Spring actuator

4.

Move the spring actuator to the desired hole

location and secure it with the bolt and the

locknut.

5.

Repeat the procedure on the remaining spring.

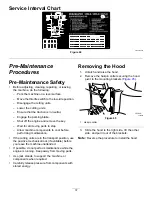

Bleeding the Fuel System

1.

Park the machine on a level surface, lower the

cutting units, engage the parking brake, shut off

the engine, and remove the key from the ignition

switch.

2.

Position the machine on a level surface, lower

the cutting units, shut off the engine, and set the

parking brake.

3.

Unlatch and raise the hood.

DANGER

Under certain conditions, diesel fuel and

fuel vapors are highly flammable and

explosive. A fire or explosion from fuel

can burn you and others and damage

property.

•

Use a funnel and fill the fuel tank

outdoors, in an open area, when the

engine is off and is cold. Wipe up any

fuel that spills.

•

Do not fill the fuel tank completely

full. Add fuel to the fuel tank until the

level is 6 to 13 mm (1/4 to 1/2 inch)

below the bottom of the filler neck.

This empty space in the tank allows

the fuel to expand.

•

Never smoke when handling fuel,

and stay away from an open flame or

where fuel fumes may be ignited by

a spark.

•

Store fuel in a clean, safety-approved

container and keep the cap in place.

4.

Open the air-bleed screw on the fuel-injection

pump (

).

g008891

Figure 38

1.

Fuel-injection pump bleed screw

5.

Turn the key in the ignition switch to the

O

N

position. The electric fuel pump begins

operation, thereby forcing air out around the

air-bleed screw.

Note:

Leave the key in the O

N

position until a

solid stream of fuel flows out around the screw.

6.

Tighten the screw and turn the key to the O

FF

position.

Note:

Normally the engine should start after the

above bleeding procedures are followed. However, if

29

Содержание 03820

Страница 53: ...Notes ...

Страница 54: ...Notes ...