13

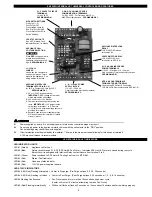

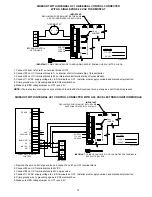

SIDESHOT WITH INTEGRAL UC1 UNIVERSAL CONTROL CONNECTED WITH A HONEYWELL R8184

SERIES OR EQUIVALENT PRIMARY CONTROL AND A BURNER MOTOR POST-PURGE

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

U

N

IVER

SAL

C

O

N

T

R

O

L

XN

BURNER

NM

T

R

M

THERMOSTAT

OIL VALVE

W

O

WHITE

ORANGE

B

F

F

T

T

IMPORTANT:

XL

J1

J2

115V

DRY

24V

D/N 9183046-4 10/16/03

115 VAC

LEGEND:

CALL

JUMPER

BLACK

HONEYWELL R8184

SERIES OR EQUIVALENT

L1 OR B1

SS2

COOLING

SS2

MOTOR

MOTOR

IGNITION

TRANS

50/60 Hz

SUPPLY

115 VAC

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

FAN

CONNECT TO

CONNECT TO

L2 OR B2

1. Separate the burner motor wire and ignition transformer from the Orange wire of R8184.

2. Connect the Orange of R8184 to #1 on UC1 terminal block.

3. Connect #2 on UC1 terminal block to White on R8184 and L2 or B2.

4. Connect the HOT wire of oil solenoid valve to #4 on UC1 terminal block and neutral wire to White or N.

5. Connect burner motor and ignition transformer HOT wires to M terminal on UC1 and neutrals to White or N.

6. Connect 115 VAC supply voltage to L & N terminals on UC1. Installer must supply overload and disconnect protection.

7. Crimp ground wire to grounding spade in SS2 electrical box.

8. Make sure RED voltage jumper on UC1 is on 115V.

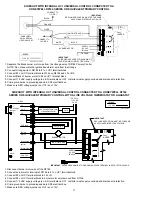

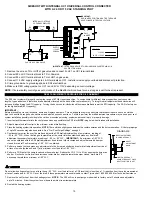

SIDESHOT WITH INTEGRAL UC1 UNIVERSAL CONTROL CONNECTED TO AN OIL-FIRED FURNACE

WITH A HONEYWELL T87 OR EQUIVALENT NON-POWERED THERMOSTAT

XN

R

UNIV

E

RS

A

L CO

NTRO

LLE

R

REMOVE JUMPER TO AVOID

AS APPLIANCE INTERLOCK VOLTAGE.

RED JUMPER POSITION MUST BE THE SAME

XL

J1

J2

DRY

115V

24V

IMPORTANT:

BACKFEEDS OR SHORT

50/60 Hz

SUPPLY

115 VAC

NON-POWERED THERMOSTAT

F

F

T

T

D/N 9183047-1

PRIMARY CONTROL

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

OR EQUIVALENT

5 VDC BOARD-GENERATED

LEGEND:

115 VAC

DO NOT SUPPLY POWER!

POWER.

LOW VAC

HONEYWELL T87 OR EQUIVALENT

W

O

WHITE

ORANGE

B

BLACK

HONEYWELL

R8184 SERIES

IMPORTANT:

FACTORY-

WIRED

CIRCUITS.

1.

IMPORTANT:

Remove J1 & J2 Call Jumper on UC1 to avoid backfeeds or short circuits.

2. Connect T87 or Equivalent non-powered thermostat to A and B terminals on UC1.

3. Remove T T Jumper from R8184 or equivalent Primary Control.

4. Connect #3 on UC1 terminal block to T terminal of Primary Control.

5. Connect #4 on UC1 terminal block to remaining T terminal of Primary Control.

6. Connect 115 VAC supply voltage to L & N terminals on UC1. Installer must supply overload and disconnect protection.

7. Crimp Ground wire to grounding spade in SS2 electrical box.

8. Make sure RED voltage jumper on UC1 is on DRY.

NOTE:

If burner safety control goes out on lockout, the SideShot will continue to run as long as a call for heat is present.