19

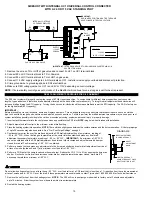

IMPELLER INSPECTION

We recommend that the SS2 impeller be inspected annually. Improper oil burner adjustment can cause excessive particulate build up over time and

impair venter performance.

NOTE:

See “SS2 Terminology” on page 3 for isometric diagram when following impeller inspection procedure.

NOTE: The following inspection procedure should be done when SS2 is mounted. Use care so hardware is not lost.

1. To examine impeller, remove vent pipe and SS2 inlet pipe by twisting counter clockwise.

2. Remove (7) screws which hold cover plate to vent cabinet.

3. Remove flexible tubing from fan prover sensing tube and remove (8) nuts which hold inlet assembly to venter housing. An impeller that exhibits large

amounts of particulate should be cleaned with a soft metal wire brush and soot cleaner. Clean each blade, as well as the rest of the impeller. An

impeller that appears to be out of round should be replaced with a new impeller. After cleaning or replacing impeller, perform “Draft Adjustment

Procedure” on pages 15, 16. If inlet assembly is removed for cleaning or replacement of impeller, make sure inlet assembly gasket is in good shape

when replacing inlet assembly. If gasket is damaged use a 1/8” bead of high temperature RTV sealant on inlet assembly before securing to venter housing.

MOTOR OILING

The SS2 Motor has sealed ball bearings and requires no oiling.

HOW TO OBTAIN SERVICE ASSISTANCE

1.

If you have any questions about your Power Venter or if it requires adjustment, repair or routine maintenance, we suggest that you contact your

installer, contractor or service agency.

2.

If you require technical information contact Tjernlund Products, Inc. at 1-800-255-4208 with the following information:

1. Model of the Power Venter as shown on the label attached to Power Venter.

2

Name and address of installer and any service agency who performed work on Power Venter.

3. Date of original installation and dates any service work was performed and details of problem.

LIMITED PARTS WARRANTY AND CLAIM PROCEDURE

Tjernlund Products, Inc. warrants the components of the SideShot for two years from date of installation. This warranty covers defects in material and

workmanship. This warranty does not cover normal maintenance, transportation or installation charges for replacement parts or any other service calls

or repairs. This warranty DOES NOT cover the complete SS2 if it is operative, except for the defective part.

Tjernlund Products, Inc. will issue credit or provide a free part to replace one that becomes defective during the two year warranty period. Proof of date

of the installation in the form of the contractor sales/installation receipt is necessary to prove the unit has been in service for under two years. All

receipts should include the date code of the SideShot to ensure that the defective component corresponds with the complete unit. This will help pre-

clude possible credit refusal.

1.) Follow troubleshooting guide to determine defective component. If unable to determine faulty component, contact your Tjernlund distributor or

Tjernlund Products Technical Customer Service Department at 1-800-255-4208 for troubleshooting assistance.

2.) After the faulty component is determined, return it to your Tjernlund distributor for replacement. Please include SideShot date code component

was taken from. The date code is located on the Electrical Box coverplate. If the date code is older than 2 years, you will need to provide a copy

of the original installation receipt to your distributor. Credit or replacement will only be issued to a Tjernlund distributor after the defective part has

been returned prepaid to Tjernlund.

WHAT IS NOT COVERED

Product installed contrary to our installation instructions, altered, neglected or misused

Product that has been wired incorrectly or damaged by a malfunctioning or maladjusted burner

Any labor charges related to evaluating and replacing the defective part or freight charges related to the return of the defective part

REPLACEMENT PARTS

Component

Part Number

SS2 Motor

950-0015

SS2 Proving Switch (Old Style metal

exterior

Junction box mount)

950-0016

SS2 Proving Switch (New Style plastic

interior

Junction box mount)

950-0029

IMPORTANT:

Old style and new style Fan Provers are not interchangeable.

Component

Part Number

SS2 Impeller

950-0017

SS2 High Limit Switch

950-0018

SS2 Venter Housing

950-0019

SS2 Cooling Fan

950-0020

Universal Control Circuit Board

950-8804

TJERNLUND LIMITED TWO YEAR WARRANTY

Tjernlund Products, Inc. warrants to the original purchaser of this product that the product will be free from defects due to faulty material or workman-

ship for a period of (2) years from the date of original purchase or delivery to the original purchaser, whichever is earlier. Remedies under this war-

ranty are limited to repairing or replacing, at our option, any product which shall, within the above stated warranty period, be returned to Tjernlund

Products, Inc. at the address listed below, postage prepaid. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON

THE FACE HEREOF, AND TJERNLUND PRODUCTS, INC. EXPRESSLY DISCLAIMS LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAM-

AGES ARISING FROM THE USE OF THIS PRODUCT. THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES AND NO AGENT

IS AUTHORIZED TO ASSUME FOR US ANY LIABILITY ADDITIONAL TO THOSE SET FORTH IN THIS LIMITED WARRANTY. IMPLIED WAR-

RANTIES ARE LIMITED TO THE STATED DURATION OF THIS LIMITED WARRANTY. Some states do not allow limitation on how long an implied

warranty lasts, so that limitation may not apply to you. In addition, some states do not allow the exclusion or limitation of incidental or consequential

damages, so that above limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights

which may vary from State to State. Send all inquiries regarding warranty work to Tjernlund Products, Inc. 1601 9th Street, White Bear Lake, MN

55110-6794. Phone (651) 426-2993 • (800) 255-4208 • Fax (651) 426-9547 • Email [email protected].