1

Address all correspondence to:

Customer Service • Tjernlund Products, Inc. • 1601 Ninth Street • White Bear Lake, MN 55110-6794

Call us toll free at 800-255-4208, visit our web site @ www.tjernlund.com or email us at [email protected].

TABLE OF CONTENTS

Description and Specifications............................................................................................................................................................1, 2

Installation Restrictions ........................................................................................................................................................................2

Cautions .................................................................................................................................................................................................3

Safety Inspection of a Previously Used Appliance .................................................................................................................................3

SideShot® Model SS2 Terminology ......................................................................................................................................................3

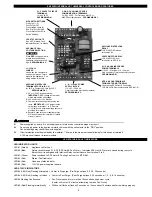

SideShot® With Integral UC1 Universal Control Board Features ..........................................................................................................4

LED Status / Fault Indicators and Fault Retrieval from Memory.........................................................................................................4, 5

Pre / Post-Purge & Prover Status Check Settings ..................................................................................................................................5

Vent Hood Termination Clearances

U.S. Installations ...................................................................................................................................................................... 6

Canadian Installations.......................................................................................................................................................... 6, 7

Installation

Tools Required ......................................................................................................................................................................7

Vent System Installation ....................................................................................................................................................8, 9

Installation of Vent Pipe ..........................................................................................................................................................9

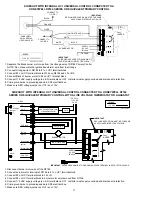

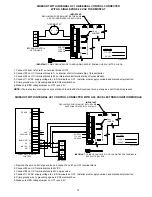

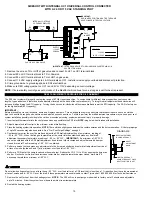

Electrical Wiring

Warnings, Sequence of Operation & Internal Schematic ....................................................................................................10

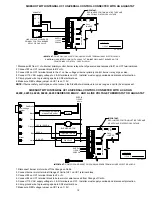

Wiring to Oil Fired Equipment ............................................................................................................................11, 12, 13, 14

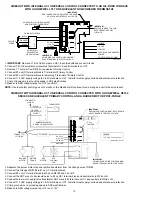

Wiring to Gas Fired Appliance .......................................................................................................................................14, 15

Draft Adjustment Procedure (Oil)....................................................................................................................................................15, 16

Draft Adjustment Procedure (Gas)........................................................................................................................................................16

Combustion Air .................................................................................................................................................................................... 16

Final System Operation Check Out .....................................................................................................................................................16

Troubleshooting Oil Odors ..............................................................................................................................................................16, 17

Troubleshooting Electrical Problems ..............................................................................................................................................17, 18

Maintenance ...................................................................................................................................................................................18, 19

How to Obtain Service ..........................................................................................................................................................................19

Warranty & Replacement Parts ............................................................................................................................................................19

SS2 Vent Cabinet Mounting Template (INSERTED)

SideShot® is a registered trademark of Tjernlund Products, Inc. for their Models SS1 & SS2 Vent Systems.

DESCRIPTION

The SS2 is a mechanical vent system designed and listed for use with natural draft oil or gas heating equipment. It is factory assembled and wired.

The SS2 automatically vents the flue gases from heating equipment to the outdoors. By recirculating indoor air with a cooling fan, surrounding com-

bustible materials remain at safe temperatures. After each burner cycle the SS2 will continue to operate in post-purge mode to purge the heater and

vent of residual flue gases. A factory post-purge time is set at 2 minutes and is adjustable up 16 minutes, see “Pre / Post-purge Settings” on page 5.

The SS2 features a safety system consisting of the integral UC1 Universal Control, a Fan Proving Switch and a High Limit temperature control. These

devices monitor the SS2’s performance and will interrupt the main burner if a venting malfunction is detected.

APPLICATION TABLE

Verify that the total BTU/hr. input of the heating appliance(s) fall within the inputs listed below. The BTU/hr. capacity range is based on a maximum of

50 equivalent feet (15 meters). To determine equivalent feet, add the total length of straight vent pipe plus 10 feet (3 meters) for each 90 degree elbow

and 5 feet (1.5 meters) for each 45 degree elbow. Vent runs of over 15 linear feet (4.5 meters) require the use of an approved, insulated vent connector

to prevent problems related to condensation.

The SS2 Vent System may only be used on Flame Retention Head Oil Burners for oil installations.

Oil burner capacities exceeding 1 GPH may require the burner to be adjusted to more efficient (12.5-13% CO2) than typical levels to maintain

recommended over-fire draft settings. See “Oil Draft Adjustment Procedure” on page 15 of this manual or consult Tjernlund at 1-800-255-4208

with questions prior to installation.

MODEL

FLAME RETENTION

FAN ASSISTED

MAX. EQUIV.

OIL BURNER

NATURAL & LP GAS

FEET

SS2

BTU / hr.

70,000 - 168,000

BTU / hr.

40,000 - 150,000

50

BTU / hr.

40,000 - 125,000

NATURAL & LP GAS

ATMOSPHERIC