40

maintenance

ProMark

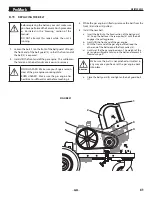

fluID SecTIoN cuT-AWAy

Peaks of upper

packings must

face up.

Torque outlet

valve housing

to 50 ft.-lbs.

(68 Nm).

Use blue

Loctite.

Oil cup area

for piston lube

packing

lubricant.

Peaks of lower

packings must

face down.

Lubricate O-ring.

fIgure 26

8.10

SAe o-rINg fITTINg INSTAllATIoN

1.

Pull washer and o-ring back as far as possible.

2.

Lubricate o-ring (1) and entrance port (2).

1

2

fIgure 27

3.

Screw fitting in until washer pushes o-ring into entrance

and sits flat against port. (Do not tighten! - only do this

step hand tight to compress o-ring into port!)

fIgure 28

4.

Back fitting out no more than one complete turn to align

as required.

fIgure 29

5.

Torque nut wrench tight holding backup on fitting (3). This

should expose a recess gap (4) behind the nut which can

act as an indicator that the fitting is assembled correctly.

4

3

fIgure 30

Attention

Avoid screwing in the fitting too far. This can

cause the washer to bend, which will cause the

O-ring to extrude.

Avoid leaving the fitting out too far. This can

lead to the O-ring being cut on the threads of the

fitting.

Содержание 200

Страница 12: ...12 description of unit ProMark 3 3 System controls FIGURE 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Страница 45: ...45 troubleshooting ProMark ...

Страница 56: ...56 Gerätebeschreibung ProMark 3 3 GERÄTESTEUERUNG abb 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Страница 89: ...89 ProMark ...

Страница 100: ...100 Description du matériel ProMark 3 3 COMMANDES DU SYSTÈME fig 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Страница 133: ...133 ProMark ...