30

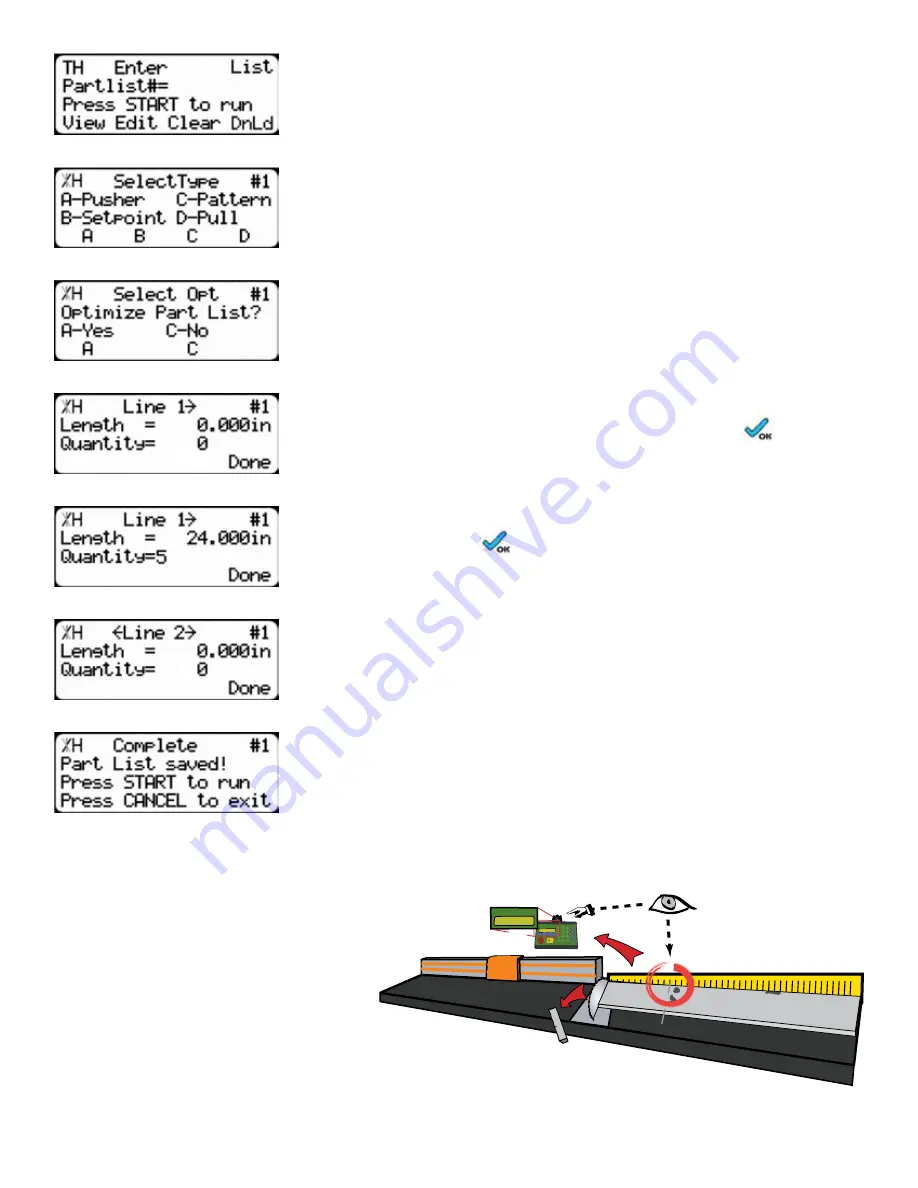

3. At the list interface, enter the list number you wish to program and

press the [Edit] soft key.

Note: The list number is a memory slot that houses the list. You can choose numbers

1 - 100.

4. Choose Set Point list.

5. TigerRack will ask if you want to optimize. Choose Yes.

Note: If you do not see this option, contact TigerStop Customer Service.

6. You will now be taken to the programming screen for line 1. Enter

the length of the part you wish to process and press

.

In this example, I will tell TigerRack I want to cut a 24 inch part.

7. The cursor will now drop to the quantity. Enter how many parts you

want, followed by

.

In this example, I will tell TigerRack that I want 5 parts.

8. You will now be taken to line 2. Repeat steps 6 and 7 until you

have entered all the parts you want to process.

Note: You can also download all the parts straight from a design file. Downloading is

a faster way of importing parts for use with TigerStop Dynamic Optimization.

9. Press the [Done] soft key once you have entered all parts.

10. The list has now been saved. Press [Start] to run the list.

Running the list

1 0

2 0

3 0

4 0

5 0

6 0

7 0

START

TigerStop

TigerStop

TigerStop

TigerStop

20in

20in

20

1. First, make your trim cut. After the

trim cut, measure up to your first

defect.

Note: If no defect is present, measure up to the

end of the material.

Содержание TigerRack

Страница 34: ...34 Date Maintenance Performed Drive Test Results Maintenance Log Maintenance Log ...

Страница 35: ...35 ...