28

Working with Part Lists

Working with Part Lists

TigerRack has a versatile part list feature that allows users to enter large lists of parts for use with the

TigerStop Dynamic Optimization upgrade. This lets the user run, view, edit, clear and optimize lists of

parts, then processes the parts quickly and accurately.

There are 4 types of lists that you can enter;

Pusher

A pusher list will tell TigerRack to push the stock material into the tool. You can enter as many parts as

you like into a pusher list and TigerRack will tell you when it needs another piece of stock. Pusher lists

can be optimized if you have the TigerStop Dynamic Optimizing upgrade.

Set Point

A set point list will tell TigerRack to act as a stop. It will treat each length you enter as an absolute value

from your zero point. Set point lists can be optimized if you have the TigerStop Dynamic Optimizing

upgrade.

Pattern

A pattern list will tell TigerRack to process one stock lengths worth of parts in a push feed fashion. It will

run the same pattern of parts over and over until its told to stop. Pattern lists cannot be optimized.

Pull

A pull list works just like a pattern except it pulls away from the zero point instead of pushing towards

it. Pull lists cannot be optimized.

Programming a List

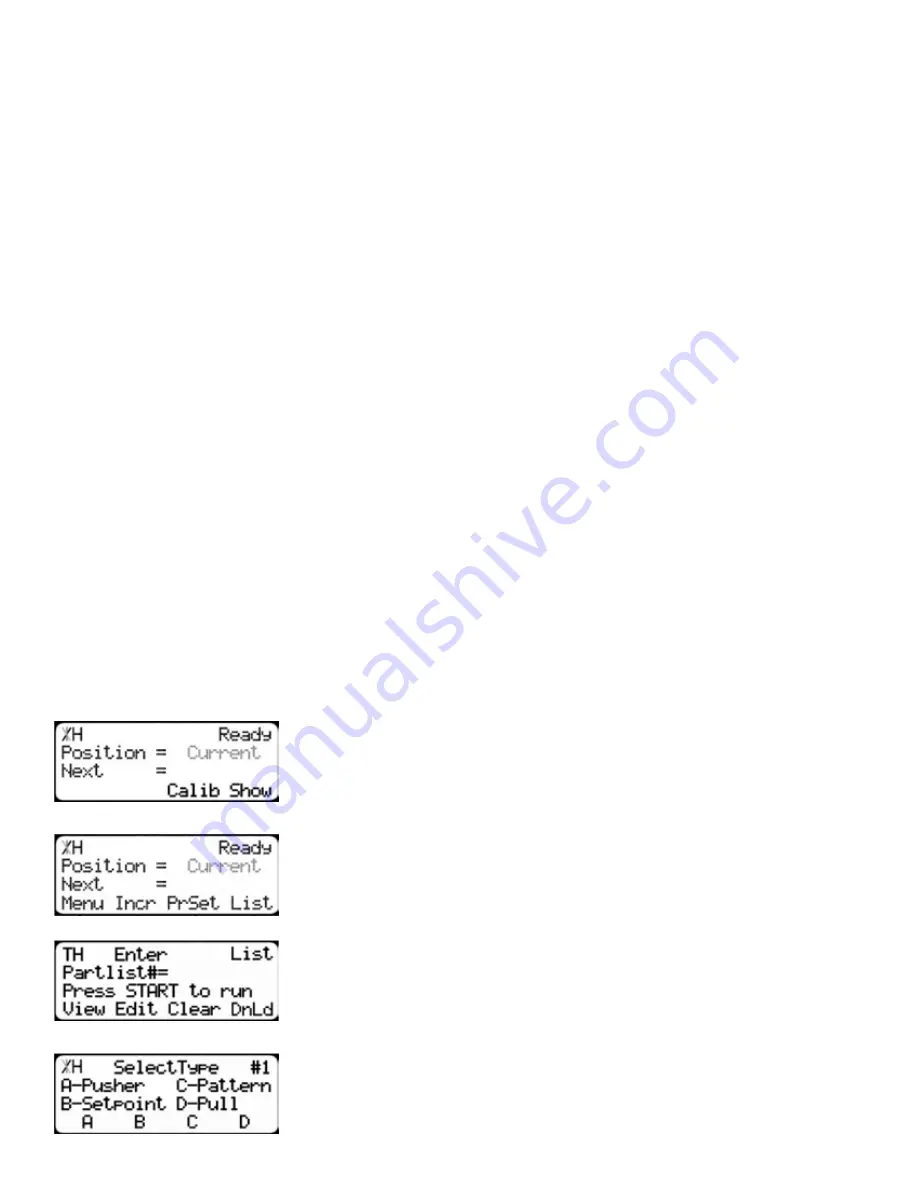

1. From the Ready Screen, press the [Show] soft key to show the menu

options.

2. A new set of soft key options have appeared. Press the [List] soft key

to access the List interface.

3. At the List interface, enter the list number you wish to program and

press the [Edit] soft key.

Note: the list number is a memory slot that houses the list. You can choose numbers

1 - 100.

4. Select the type of list you would like to program.

Содержание TigerRack

Страница 34: ...34 Date Maintenance Performed Drive Test Results Maintenance Log Maintenance Log ...

Страница 35: ...35 ...